Method for efficiently converting nitrate nitrogen in nitrate waste liquid into nitrite nitrogen

A technology of nitrite nitrogen and nitrate, applied in chemical instruments and methods, light water/sewage treatment, water pollutants, etc., can solve problems such as secondary pollution, improve waste liquid, etc., achieve high-efficiency conversion, and simple operation process , the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

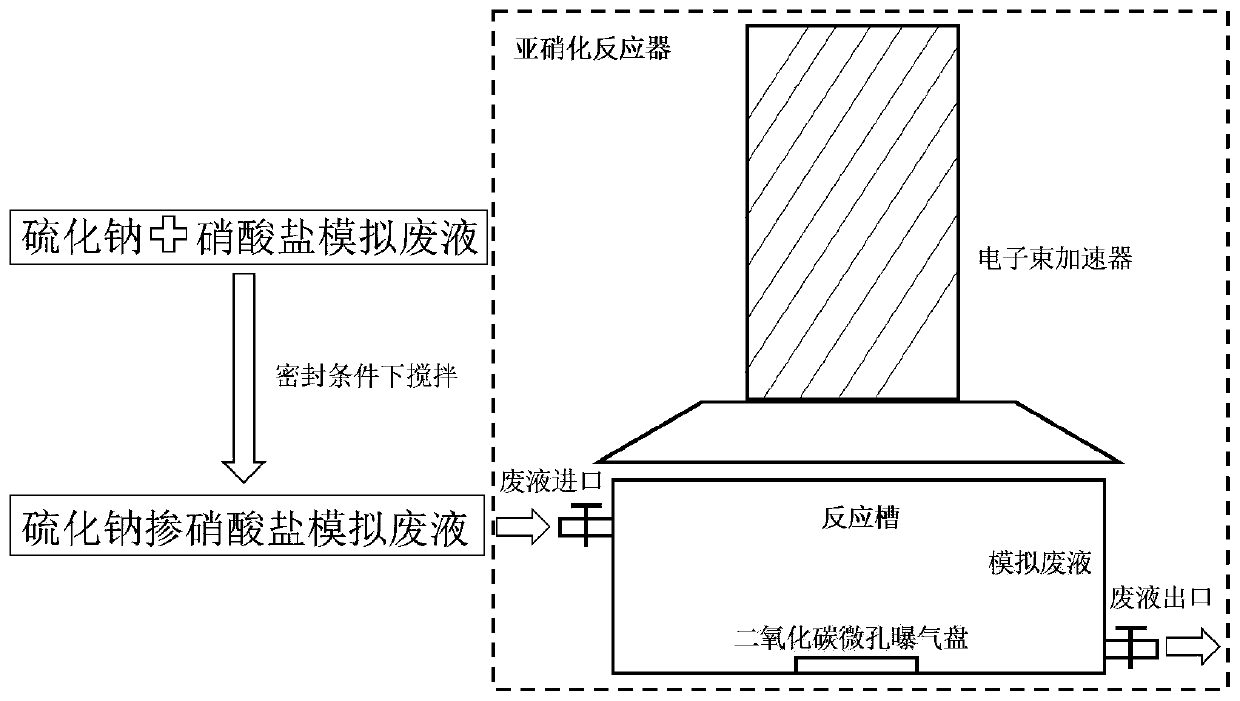

[0019] Example 1 Effect of solid-liquid ratio of sodium sulfide and nitrate waste liquid on the disposal performance of electron beam irradiated nitrate waste liquid

[0020] Preparation of simulated nitrate waste liquid: Weigh sodium nitrate and water according to the solid-to-liquid ratio of 5:100 mg / mL, dissolve sodium nitrate in water, and stir under sealed conditions until the sodium nitrate is completely dissolved to obtain simulated nitrate waste liquid.

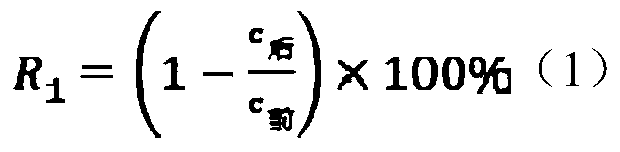

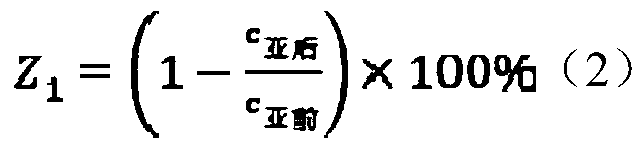

[0021] Disposal of nitrate simulated waste liquid: according to the ratio of solid to liquid: 0.01:1mg / mL, 0.015:1mg / mL, 0.018:1mg / mL, 0.02:1mg / mL, 0.03:1mg / mL, 0.04:1mg / mL, 0.05:1mg / mL, 0.052: 1mg / mL, 0.055: 1mg / mL, 0.06: 1mg / mL respectively weighed sodium sulfide and nitrate simulated waste liquid, dissolved sodium sulfide into the nitrate waste liquid, and stirred it under sealed condition until it vulcanized Sodium is completely dissolved to obtain sodium sulfide mixed with nitrate liquid. Wherein, the nitrate c...

Embodiment 2

[0030] Example 2 Influence of injection height of nitrate simulated waste liquid in reaction tank on disposal performance of electron beam irradiated nitrate simulated waste liquid

[0031] Preparation of simulated nitrate waste liquid: Weigh sodium nitrate and water according to the solid-to-liquid ratio of 15:100 mg / mL, dissolve sodium nitrate in water, stir under sealed conditions until sodium nitrate is completely dissolved, and obtain simulated nitrate waste liquid

[0032] Disposal of simulated nitrate waste liquid: Weigh sodium sulfide and simulated nitrate waste liquid according to the solid-to-liquid ratio of 0.05:1mg / mL, dissolve sodium sulfide into simulated nitrate waste liquid, and stir until sodium sulfide is completely dissolved under sealed conditions , to get sodium sulfide mixed with nitrate simulated waste liquid. Wherein, the nitrate concentration in the above nitrate simulation waste liquid is 150mg / L. The sodium sulfide mixed with nitrate simulated waste...

Embodiment 3

[0037] Example 3 Effect of carbon dioxide gas ventilation on the disposal performance of electron beam irradiated nitrate simulated waste liquid

[0038] Preparation of simulated nitrate waste liquid: Weigh sodium nitrate and water according to the solid-to-liquid ratio of 25:100 mg / mL, dissolve sodium nitrate in water, stir under sealed conditions until sodium nitrate is completely dissolved, and obtain simulated nitrate waste liquid

[0039] Disposal of simulated nitrate waste liquid: Weigh sodium sulfide and simulated nitrate waste liquid according to the solid-to-liquid ratio of 0.05:1mg / mL, dissolve sodium sulfide into simulated nitrate waste liquid, and stir until sodium sulfide is completely dissolved under sealed conditions , to get sodium sulfide mixed with nitrate simulated waste liquid. Wherein, the nitrate concentration in the above-mentioned nitrate simulated waste liquid is 250 mg / L. The sodium sulfide mixed with nitrate simulated waste liquid was introduced int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com