Process method for continuous production of 2,2-dimethylolbutyric acid by using microreactor

A technology of dimethylol butyric acid and dimethylol butyraldehyde, which is applied in the field of continuous production of 2,2-dimethylol butyric acid using microreactors, can solve complex reactions, high energy consumption, and many by-products and other problems, to achieve the best metal ion content, reduce waste water discharge, and reduce the effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

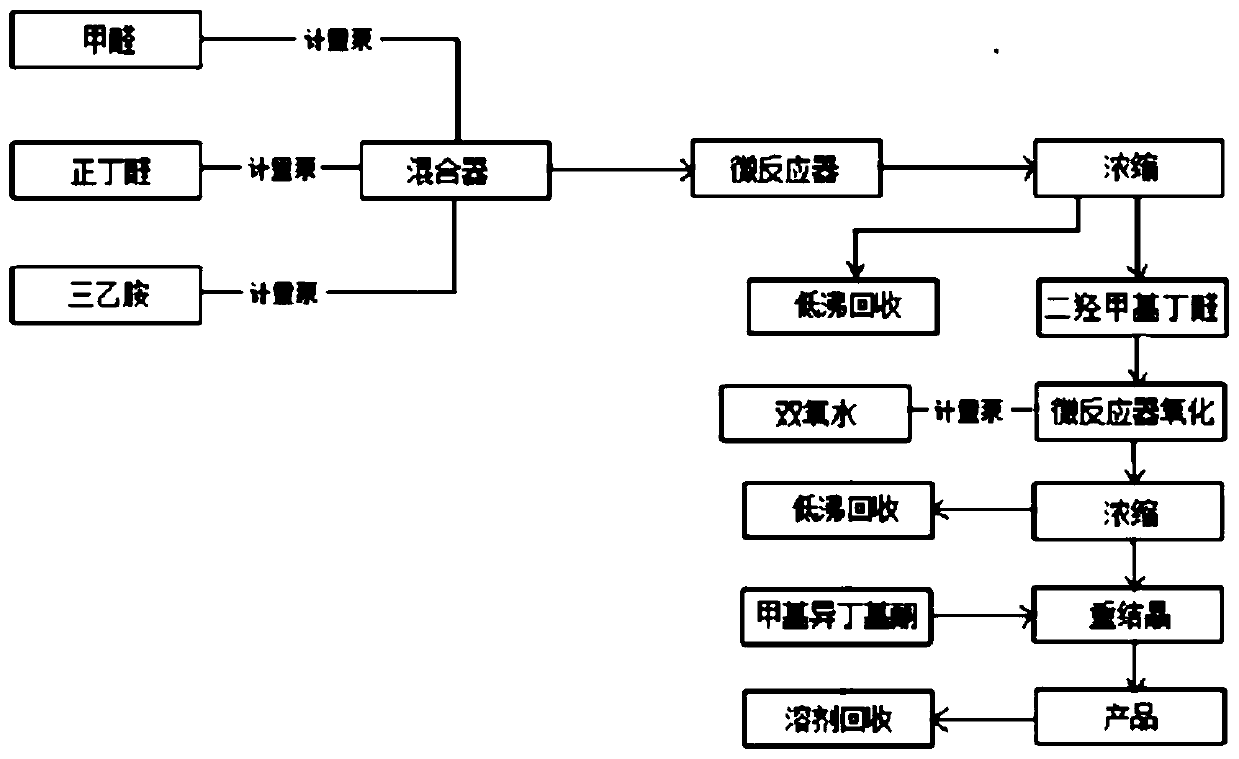

[0025] Embodiment 1, a kind of processing method that uses microreactor to continuously produce 2,2-dimethylol butyric acid, comprises the steps:

[0026] S1. Formaldehyde, butyraldehyde and triethylamine measured and quantified by a metering pump are placed in a mixer for forced mixing, and then enter the microreactor for condensation reaction. The flow rates of triethylamine, formaldehyde and n-butyraldehyde are respectively 250ml / minutes, 2000ml / min, 1100ml / min, the flow rate of triethylamine, formaldehyde, and n-butyraldehyde is 0.1m / s, the reaction temperature is 50°C, the pressure is 0.2MPa, the reaction residence time is 70 seconds, and the mixer is connected with three Metering pump and a microreactor, the material of the mixer and microreactor can be any one or more of glass, stainless steel, resin and silicon carbide, and one or more microreactors can be used in series. A heat exchanger is installed inside the device to obtain a reaction solution mainly containing 2...

Embodiment 2

[0030] Embodiment 2, a kind of processing method that uses microreactor to continuously produce 2,2-dimethylol butyric acid, comprises the steps:

[0031] S1. Formaldehyde, butyraldehyde and triethylamine measured and quantified by a metering pump are placed in a mixer for forced mixing, and then enter the microreactor for condensation reaction. The flow rates of triethylamine, formaldehyde and n-butyraldehyde are respectively 250ml / minutes, 2000ml / min, 1100ml / min, the flow velocity of triethylamine, formaldehyde, and n-butyraldehyde is 0.2m / s, the reaction temperature is 80°C, the pressure is 0.4MPa, the reaction residence time is 100 seconds, and the mixer is connected with three Metering pump and a microreactor, the material of the mixer and microreactor can be any one or more of glass, stainless steel, resin and silicon carbide, and one or more microreactors can be used in series. A heat exchanger is installed inside the device to obtain a reaction solution mainly contain...

Embodiment 3

[0035] Embodiment 3, a kind of processing method that uses microreactor to continuously produce 2,2-dimethylol butyric acid, comprises the steps:

[0036]S1. Formaldehyde, butyraldehyde and triethylamine measured and quantified by a metering pump are placed in a mixer for forced mixing, and then enter the microreactor for condensation reaction. The flow rates of triethylamine, formaldehyde and n-butyraldehyde are respectively 250ml / minutes, 2000ml / min, 1100ml / min, the flow velocity of triethylamine, formaldehyde and n-butyraldehyde is 0.5m / s, the reaction temperature is 50°C, the pressure is 0.6MPa, the reaction residence time is 120 seconds, and the mixer is connected with three Metering pump and a microreactor, the material of the mixer and microreactor can be any one or more of glass, stainless steel, resin and silicon carbide, and one or more microreactors can be used in series. A heat exchanger is installed inside the device to obtain a reaction solution mainly containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com