Novel solar flexible module film laminating process

A solar module and flexible module technology, applied in the direction of electrical components, semiconductor devices, climate sustainability, etc., can solve the problems of ETFE film wrinkles, weak, shifted EVA adhesion, etc., to avoid waste and improve adhesion The effect of high stability and good processing and forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

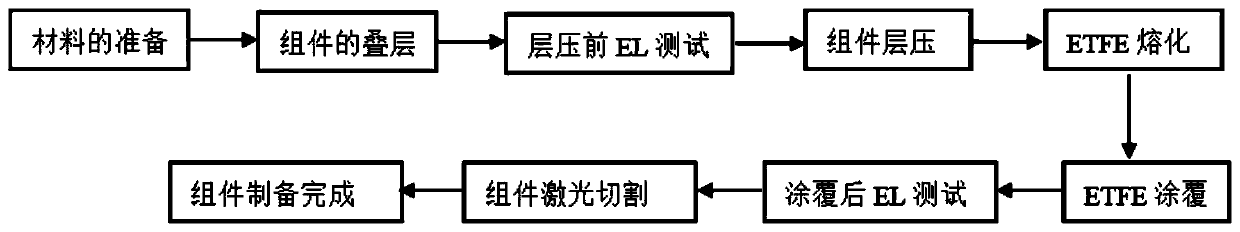

[0019] Example: such as figure 1 Shown, a kind of lamination process of novel solar energy flexible component, described process method comprises: S1: prepare required material: solar TPT back plate, solar cell sheet, EVA adhesive film (ethylene-vinyl acetate copolymer), ETFE ( Ethylene-tetrafluoroethylene copolymer);

[0020] S2: Lamination, from the bottom to the top, the solar TPT backplane, EVA film, solar cell, and EVA film are laminated sequentially;

[0021] In this embodiment, the solar TPT backplane has a thickness of 2-3 mm, the EVA adhesive film has a thickness of 0.3-0.8 mm, and the solar cell is a crystalline silicon cell.

[0022] S3: EL test before lamination, through the EL detector to detect whether the solar module is damaged during the lamination process;

[0023] S4: Lamination, put the solar modules that have passed the EL test on the loading table of the laminator, and package the components in an environment of 142 degrees Celsius. It should be noted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com