Lithium-ion battery negative electrode pole piece, preparation method thereof and lithium-ion secondary battery

A technology of lithium ion battery and negative pole piece, applied in the field of lithium ion battery negative pole piece and lithium ion secondary battery, can solve the problems of inability to meet industrial demands, low theoretical specific capacity, etc. High capacity and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of a kind of lithium-ion battery negative pole sheet of the present embodiment comprises the following steps:

[0029] Step 1, select a 100 μm pure tin metal foil as a self-supporting negative electrode;

[0030] Step 2, wipe the surface of the self-supporting negative electrode with alcohol, remove the stains on the surface, and dry it. Cut the dried self-supporting negative electrode into discs with a diameter of 12 mm to obtain battery pole pieces;

[0031] In step 3, the battery pole piece is placed in a vacuum oven at 80° C. for 6 hours to 12 hours to obtain a lithium ion battery negative pole piece.

[0032] In this example, CR2025 button-type lithium iron phosphate / / tin full battery and tin / / lithium half-cell were assembled in a glove box with both water and oxygen content 6 ) were dissolved in DEC and EC solvents with a volume ratio of 1:1 and a ceramic separator was assembled into a secondary battery.

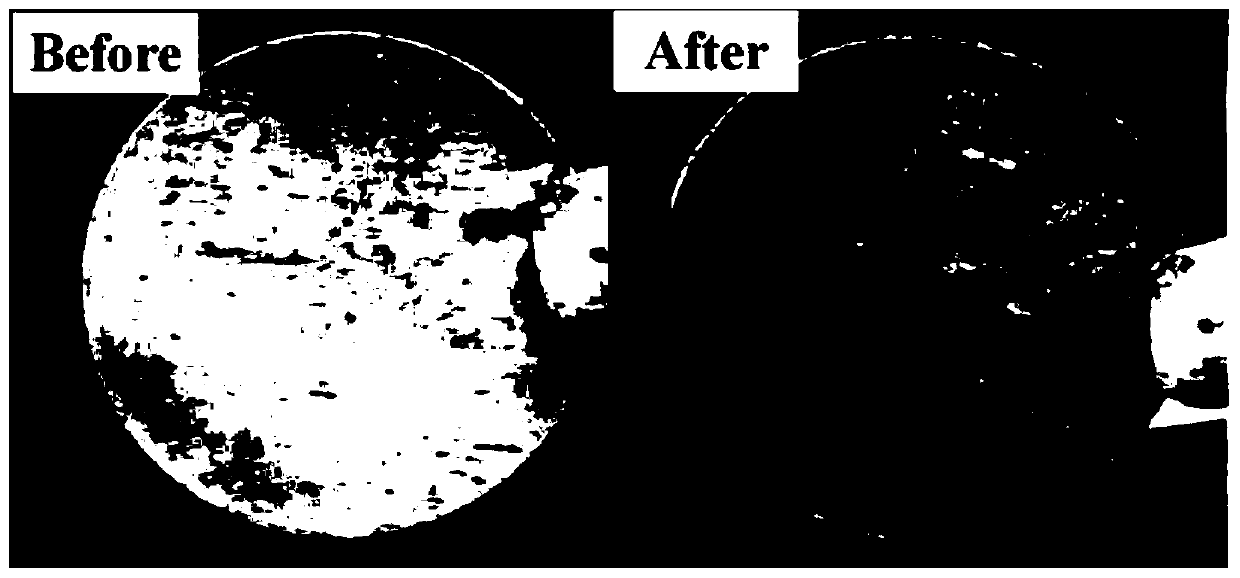

[0033] figure 1 It is the physic...

Embodiment 2

[0038] The preparation method of a kind of lithium-ion battery negative pole sheet of the present embodiment comprises the following steps:

[0039] Step 1, selecting 15 μm-100 μm tin-copper alloy containing 0.7wt% copper as the metal foil for the negative electrode;

[0040] Step 2, wipe the surface of the negative electrode with metal foil with alcohol, after drying, cut it into discs with a diameter of 12mm to obtain battery pole pieces;

[0041] In step 3, the battery pole piece is placed in a vacuum oven at 80° C. for 6 hours to 12 hours to obtain a lithium ion battery negative pole piece.

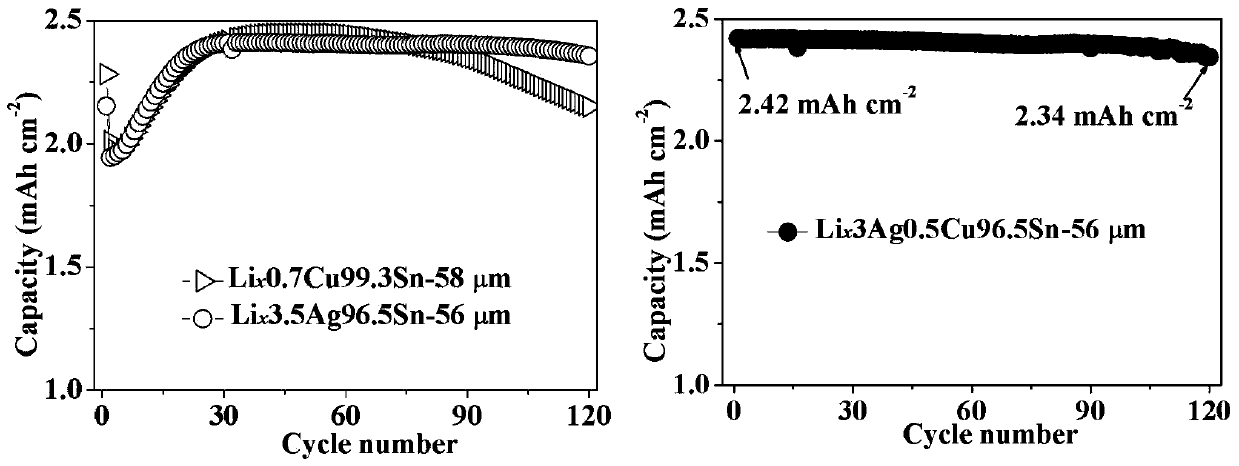

[0042] In this embodiment, a button-type full battery is assembled by using the lithium-ion battery negative pole piece and the lithium iron phosphate positive pole in a glove box where the water oxygen content is <0.1 ppm.

Embodiment 3

[0044] The preparation method of a kind of lithium-ion battery negative pole sheet of the present embodiment comprises the following steps:

[0045] Step 1, selecting 15 μm-100 μm tin-silver alloy foil material containing 3.5wt% silver as the metal foil for the negative electrode;

[0046] Step 2, wipe off the stains with alcohol on the surface of the metal foil for the negative electrode, dry it, and cut it into discs with a diameter of 12mm to obtain battery pole pieces;

[0047] In step 3, the battery pole piece is placed in a vacuum oven at 80° C. for 6 hours to 12 hours to obtain a lithium ion battery negative pole piece.

[0048]In this embodiment, a button-type full battery is assembled by using the lithium-ion battery negative pole piece and the lithium iron phosphate positive pole in a glove box where the water and oxygen content must meet <0.1ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com