Slurry for reducing graphene oxide in predetermined pattern, method of use and obtained graphene film layer

A technology of predetermined pattern and graphene film, applied in the direction of graphene, nano-carbon, etc., can solve the problems of unsuitability, harsh environmental requirements, long lithography process, etc., and achieve the effect of clear edge and complete pattern.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

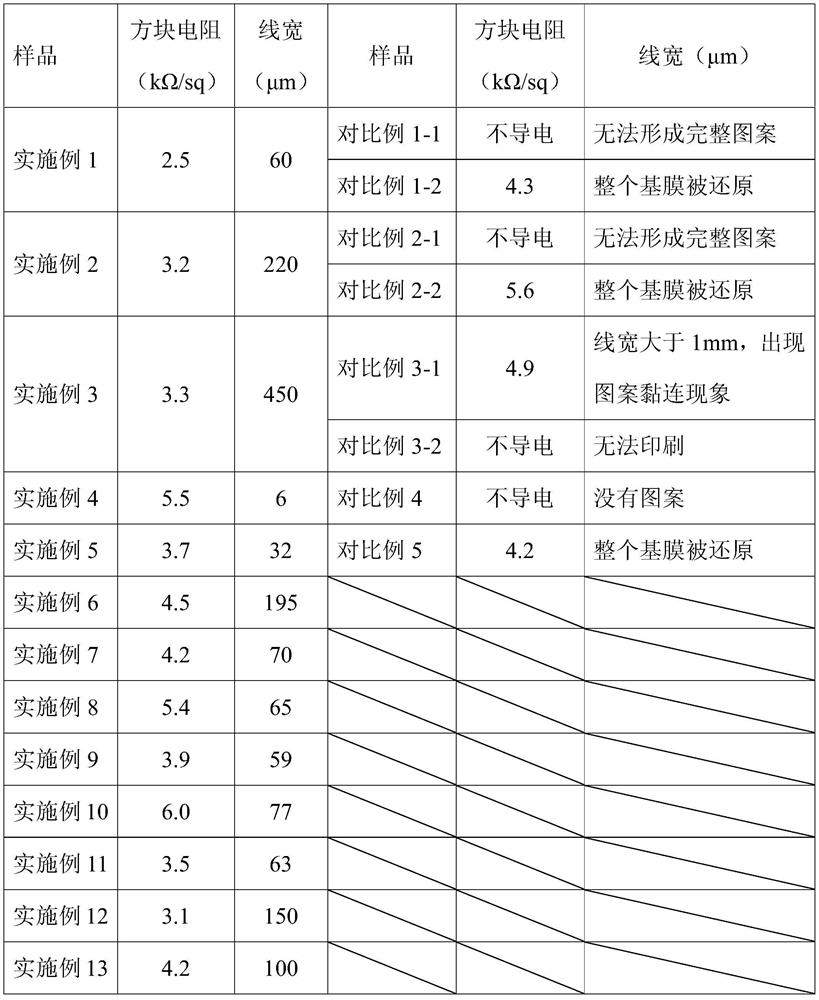

Embodiment 1

[0053] A method for preparing a patterned graphene film, comprising the steps of:

[0054] (1) Prepare a 10nm thick graphene oxide film on the PET film surface by spin coating;

[0055] (2) According to aluminum powder (particle diameter is 10 μm) 50wt%, polyester resin (weight average molecular weight is greater than 100,000) 10wt%, the ratio preparation slurry of N-methylpyrrolidone 40wt%, records the viscosity of described slurry is 1000 centipoise;

[0056] (3) The slurry of step (2) is coated on the surface of the graphene oxide film prepared in step (1) by screen printing, and the line width is 50 μm;

[0057] (4) Stand at a temperature of 50°C for 1 min, dry for 5 min, pickle for 1 min, wash with water for 2 min, and dry for 1 min to obtain a graphene patterned film with a line width of 60 μm, clear edges, and a complete graphene film layer. The thickness of the graphene patterned film was measured to be about 10 nm.

Embodiment 2

[0065] A method for preparing a patterned graphene film, comprising the steps of:

[0066] (1) Prepare a 1 μm thick graphene oxide film on the surface of the PET film by dipping;

[0067] (2) Prepare the slurry according to the ratio of 30wt% of zinc powder (2 μm in particle size), 5wt% of polyurethane (250,000 weight average molecular weight), and 65wt% of DMF (N,N-dimethylformamide), and the measured viscosity is 800 centipoise;

[0068] (3) Applying the slurry of step (2) to the surface of the graphene oxide film prepared in step (1) by screen printing, the line width is 200 μm;

[0069] (4) Stand at a temperature of 30°C for 5 minutes, dry for 5 minutes, pickle for 1 minute, wash with water for 2 minutes, and dry for 10 minutes to obtain a graphene patterned film with a line width of 220 μm, clear edges, and a complete graphene film layer. The thickness of the graphene patterned film was measured to be about 1 μm.

Embodiment 3

[0077] A method for preparing a patterned graphene film, comprising the steps of:

[0078] (1) Prepare a 10 μm thick graphene oxide film on the surface of the PP film by extrusion coating;

[0079] (2) According to stannous chloride 30wt%, PVP (polyvinylpyrrolidone) (weight-average molecular weight is 150,000) 15wt%, DMSO (dimethyl sulfoxide) 55wt% ratio preparation slurry, record viscosity is 400 centimeters Park;

[0080] (3) coating the slurry of step (2) on the surface of the graphene oxide film prepared in step (1) by gravure printing, with a line width of 500 μm;

[0081] (4) Stand at a temperature of 40°C for 10 minutes, dry for 10 minutes, pickle for 5 minutes, wash with water for 5 minutes, and dry for 15 minutes to obtain a graphene patterned film with a line width of 450 μm, clear edges, and a complete graphene film layer. The thickness of the graphene patterned film was measured to be 9.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com