Method and system for preparing dry desulfurization ash into desulfurization gypsum by using social waste acid

A dry-process desulfurization ash and desulfurization gypsum technology, applied in calcium/strontium/barium sulfate, cement production, etc., can solve the problems of secondary pollution and the difficulty of industrialization of desulfurized gypsum, and achieve the effect of solving secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

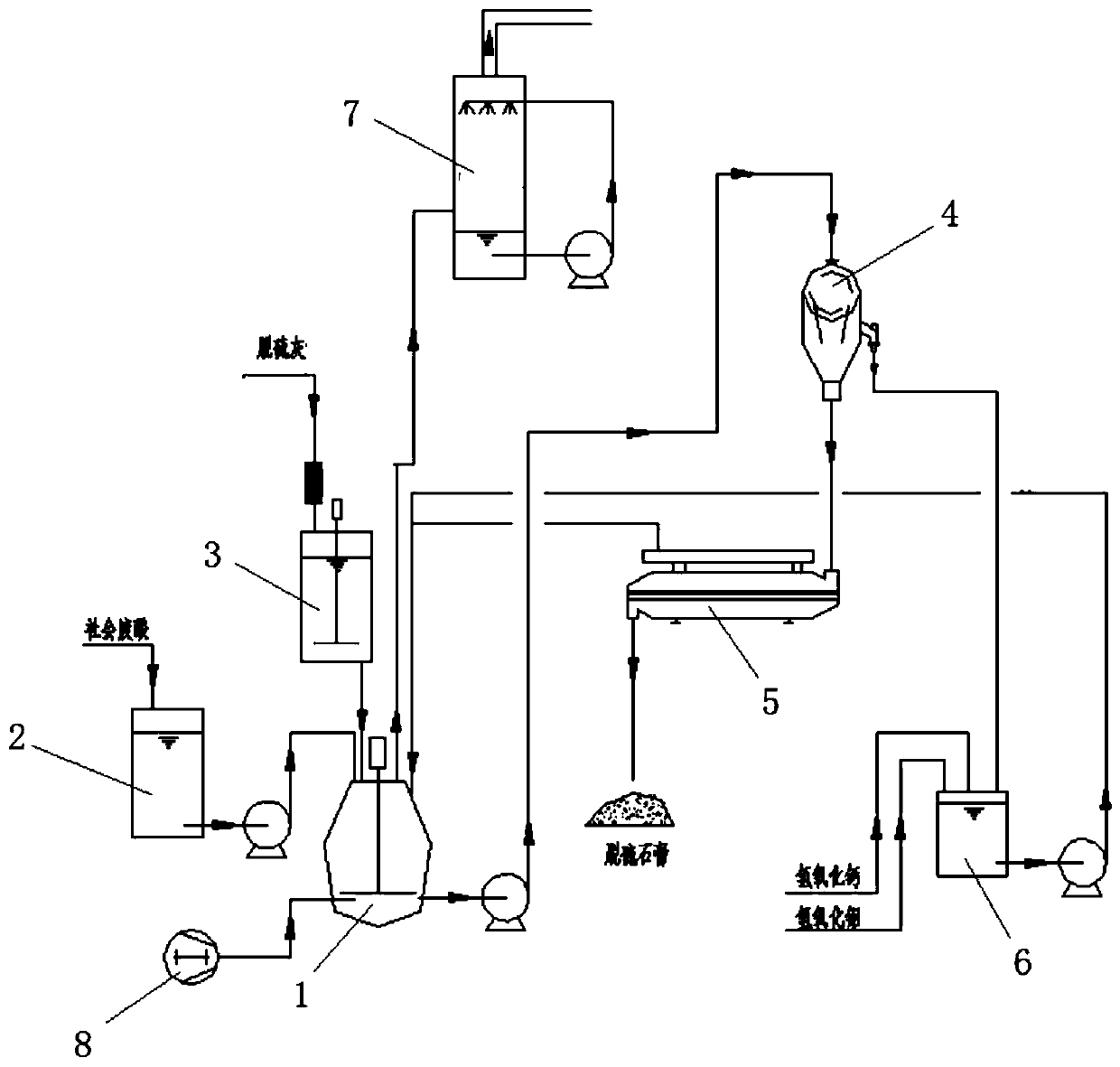

[0026] The present invention will be further described below in conjunction with embodiment.

[0027] A method for preparing desulfurized gypsum by using social waste acid to dry desulfurized ash, comprising the following steps:

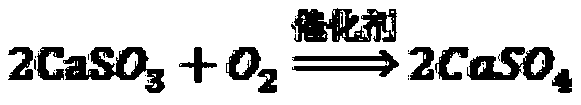

[0028] 1) Pass water into the slurry tank 3 with stirring function, and add the dry desulfurization ash to be oxidized, start the mixer, and stir it into a dry desulfurization ash solution; in the dry desulfurization ash, CaSO 3 1 / 2H 2 The mass fraction of O is 10-70%, CaCl 2 The mass fraction is 1.5-2%; the addition ratio of dry desulfurization ash and water is 1:5-1:4. If the solid-liquid ratio of dry desulfurization ash solution is high, there will be calcium sulfite that cannot be converted, resulting in a low conversion rate; if the solid-liquid ratio is reduced, the conversion rate will increase, but the production efficiency is low, which is not conducive to large-scale production.

[0029] 2) Pass the dry desulfurization ash solution into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com