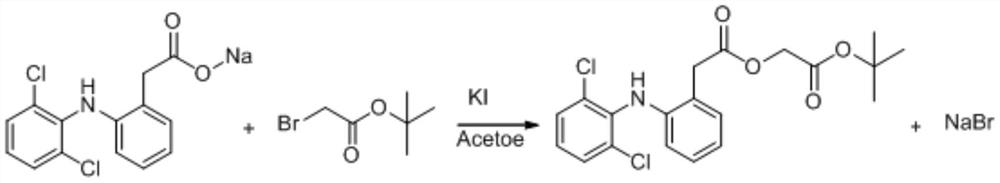

A kind of method for producing aceclofenac tert-butyl ester

A technology of aceclofenac and tert-butyl bromoacetate, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of large discharge of organic waste solvents, low process safety factor, and difficult product separation and other issues, to achieve the effect of sufficient response, process safety and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 100g of water to a 250ml three-necked flask, turn on stirring, add 20g (80%, 50.31mmol) of crude diclofenac sodium (DOS5), add 16.7g (85.64mmol, 1.7eq) of tert-butyl bromoacetate, 0.6g (3.614mmol) , 0.07eq) potassium iodide, 1.6g (4.713mmol, 0.09eq) tetrabutylammonium hydrogen sulfate, turn on the heating, heat up to 60 ℃, start to keep warm, control the temperature at 60-65 ℃, keep warm for 2 hours, slowly cool down to the temperature The temperature was 5-15°C, kept at 5-15°C for half an hour, and vacuum filtered to obtain a brownish-yellow solid. The solid was washed with ethanol 3 times the mass of DOS5 until off-white, and dried at 60°C for 30 hours to obtain 17.3 g of aceclofenac tert-butyl ester. The yield was 94.5%, and the liquid phase purity was 99.62%.

Embodiment 2

[0020] Add 500g of water to a 1000ml three-necked flask, turn on stirring, add 100g (80%, 251.6mmol) of crude diclofenac sodium (DOS5), add 73.6g (377.4mmol, 1.5eq) of tert-butyl bromoacetate, 2.9g (17.61mmol) , 0.07eq) potassium iodide, 7.7g (22.64mmol, 0.09eq) tetrabutylammonium hydrogen sulfate, turn on the heating, heat up to 60 ℃, start to keep warm, control the temperature at 60-65 ℃, keep warm for 2.5 hours, slowly cool down to the temperature The temperature was 5-15°C, kept at 5-15°C for half an hour, and vacuum filtered to obtain a brownish-yellow solid. The solid was washed with ethanol 3 times the mass of DOS5 to off-white, and dried at 60°C for 30 hours to obtain 88.7 g of aceclofenac tert-butyl ester. The yield was 94.16%, and the liquid phase purity was 99.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com