Composite ceramic, preparation method and application in selenium extraction

A technology of composite ceramics and porous ceramics, applied in the field of ceramic materials, can solve the problems of low separation efficiency of low-concentration selenium, limited application, slow processing speed, etc., to promote environment-friendly and resource-saving, and improve resource utilization. , improve the effect of environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of composite ceramics, comprising the steps of:

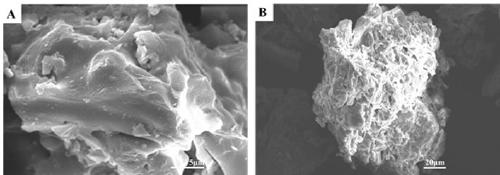

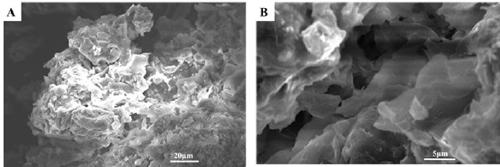

[0036] a) Collect ordinary red bricks, mechanically crush, grind and sieve them to obtain brick slag powder. Immerse 5g of brick slag powder into 100mL of hydrochloric acid solution with a concentration of 0.1mol / L, let it stand for 3h, repeat the immersion for 5 times, then filter with suction, then wash with distilled water until neutral, and then wash with ethanol twice. Finally, the brick slag powder obtained by suction filtration was dried at 80° C. for 12 hours to obtain a pretreated ceramic material.

[0037] b) Add 5g of the pretreated ceramic material to 100mL of aluminum sol with an aluminum concentration of 0.4mol / L, let it stand for 1 hour, filter it with suction, dry it at 80°C for 4 hours, then calcinate it at 500°C for 5 hours, repeat the above impregnation-pumping Filtration-drying-calcination was performed four times to obtain an aluminum-modified ceramic material.

[0038] c) Prep...

Embodiment 2

[0042] A preparation method of composite ceramics, comprising the steps of:

[0043] a) Collect ordinary hollow bricks, mechanically crush, grind and sieve them to obtain brick slag powder. Immerse 5g of brick slag powder into 100mL of hydrochloric acid solution with a concentration of 0.1mol / L, let it stand for 4h, repeat the immersion for 5 times, then filter with suction, then wash with distilled water until neutral, and then wash with ethanol twice. Finally, the brick slag powder obtained by suction filtration was dried at 80° C. for 12 hours to obtain a pretreated ceramic material.

[0044] b) Add 5g of the pretreated ceramic material to 100mL of aluminum sol with an aluminum concentration of 0.4mol / L, let it stand for 1 hour, filter it with suction, dry it at 80°C for 4 hours, then calcinate it at 500°C for 5 hours, repeat the above impregnation-pumping Filtration-drying-calcination was performed four times to obtain an aluminum-modified ceramic material.

[0045] c) P...

Embodiment 3

[0049] A preparation method of composite ceramics, comprising the steps of:

[0050] a) Collect ordinary hollow bricks and mixed red bricks, mechanically pulverize, grind and sieve them to obtain brick slag powder. Immerse 5g of brick slag powder into 100mL of hydrochloric acid solution with a concentration of 0.1mol / L, let it stand for 5h, repeat the immersion 8 times, then filter with suction, then wash with distilled water until neutral, and then wash with ethanol twice. Finally, the brick slag powder obtained by suction filtration was dried at 80° C. for 12 hours to obtain a pretreated ceramic material.

[0051] b) Add 5g of the pretreated ceramic material to 100mL of aluminum sol with an aluminum concentration of 0.4mol / L, let it stand for 1 hour, filter it with suction, dry it at 80°C for 4 hours, then calcinate it at 500°C for 5 hours, repeat the above impregnation-pumping Filtration-drying-calcination was performed four times to obtain an aluminum-modified ceramic mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com