High-capacity lithium thionyl chloride energy type battery and preparation method thereof

A lithium thionyl chloride, energy-based technology, applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve problems such as poor contact between cells, poor current collection efficiency, and complicated installation process, achieving extremely easy installation, Space-saving and small increase in internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following specific examples illustrate the present invention in further detail.

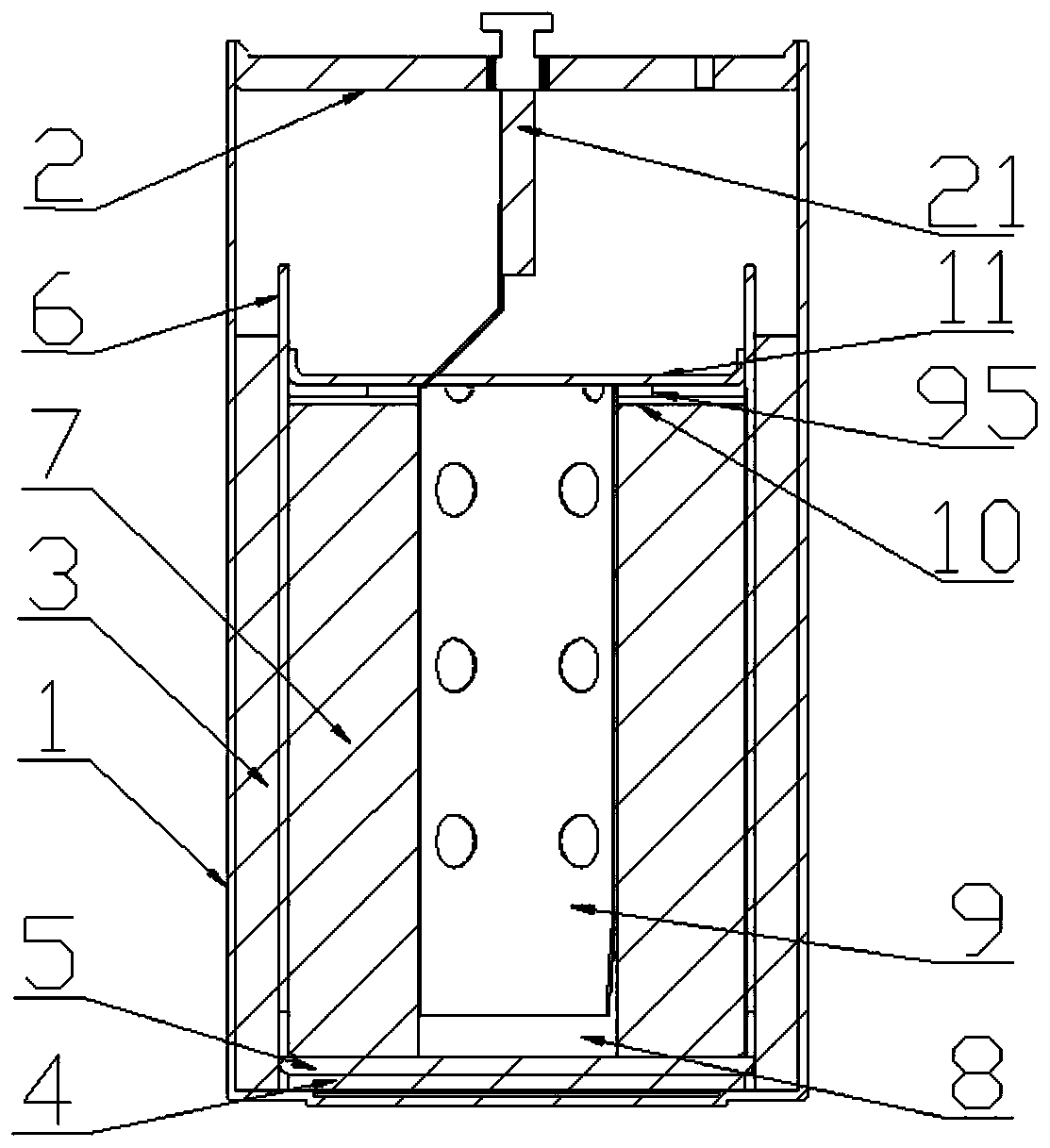

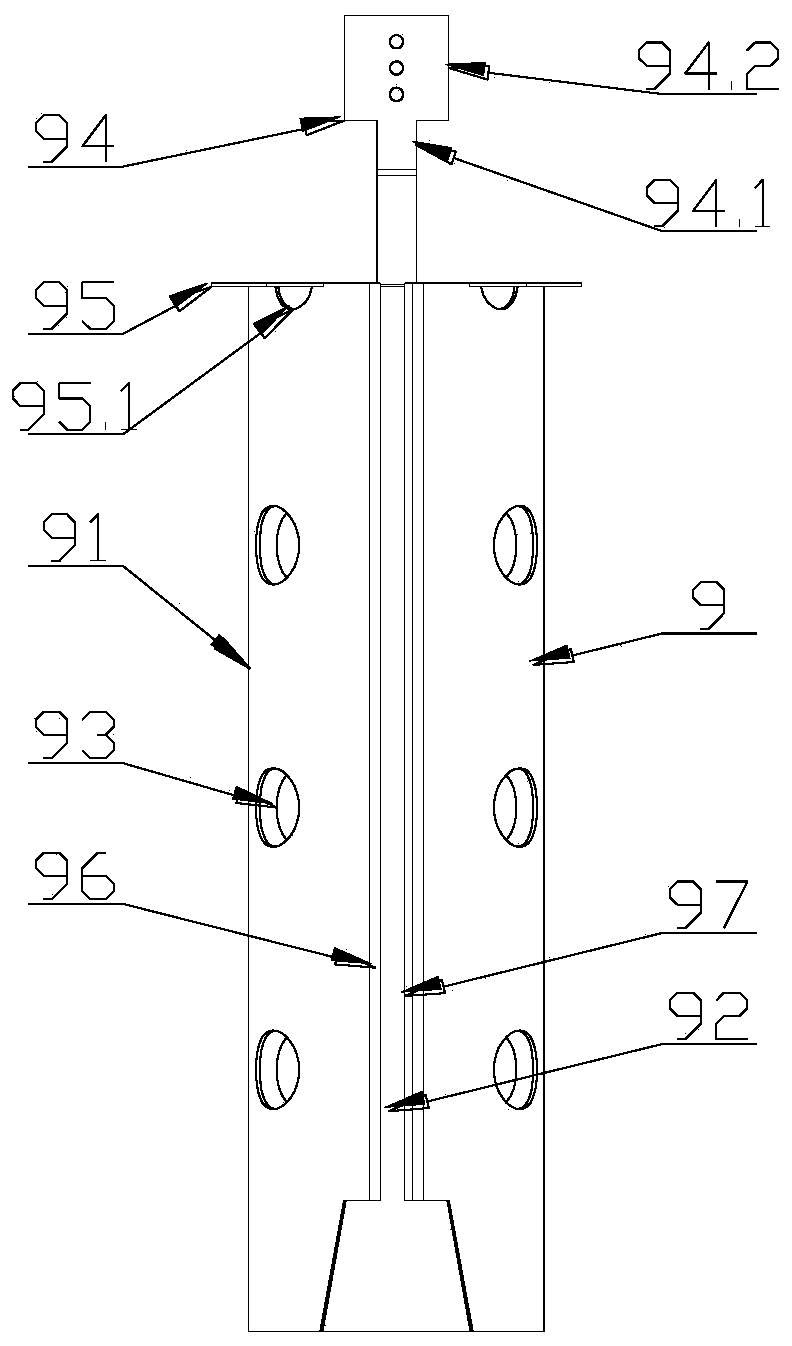

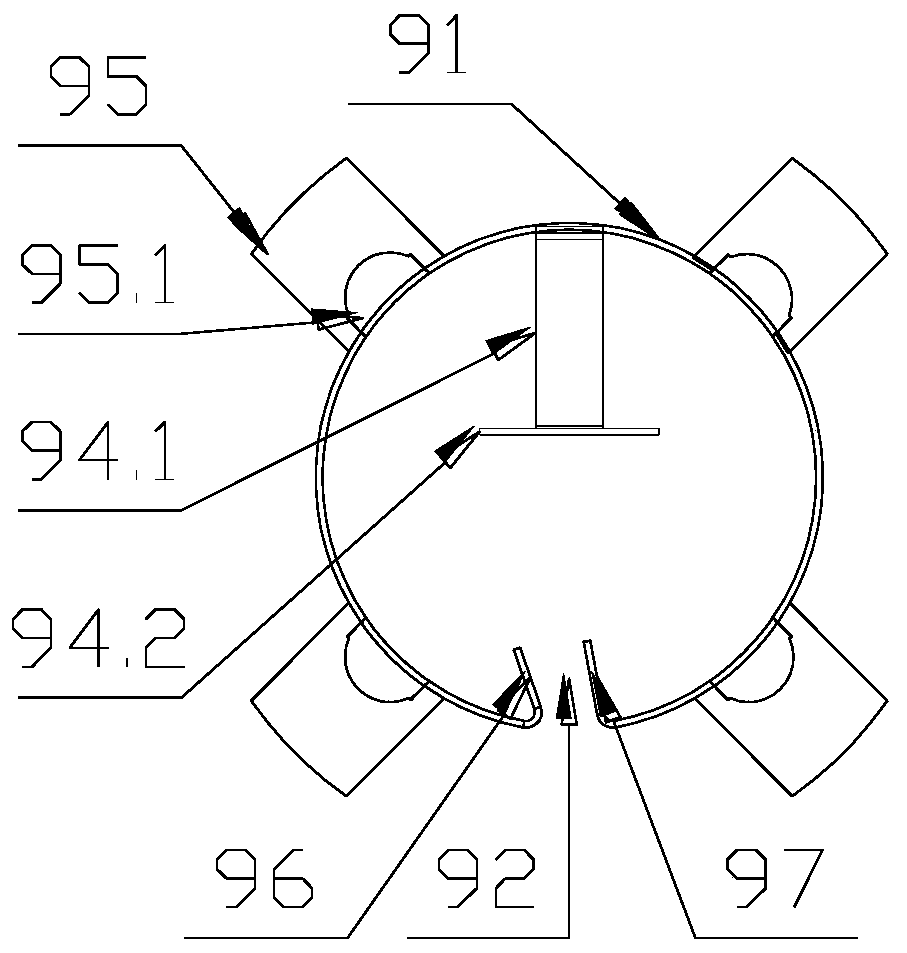

[0048] Such as figure 1 As shown, the present invention provides a high-capacity lithium thionyl chloride energy battery, comprising a casing 1, a positive electrode cover group 2 on the top of the casing 1, an annular negative lithium sheet 3 close to the inner wall of the casing 1, and the casing 1 The bottom is provided with a circular first bottom film 4 and a bowl-shaped second bottom film 5. The inner wall of the negative lithium sheet 3 is provided with a side separator 6, and the negative lithium sheet 3 is provided with a side separator 6 close to the side. The cylindrical positive carbon ring 7 formed by pressing the material, the positive carbon ring 7 is provided with a cavity 8 for filling the electrolyte, the inner wall of the positive carbon ring 7 is closely attached to a current collector 9, and the top of the positive carbon ring 7 is provided with a The current coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com