Monoatomic catalyst, and preparation method and applications thereof

A catalyst and atom technology, applied in the field of single-atom catalyst and its preparation, can solve the problem of insufficient photocatalytic activity, and achieve the effects of good photocatalytic activity, improved photocatalytic activity, and high hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

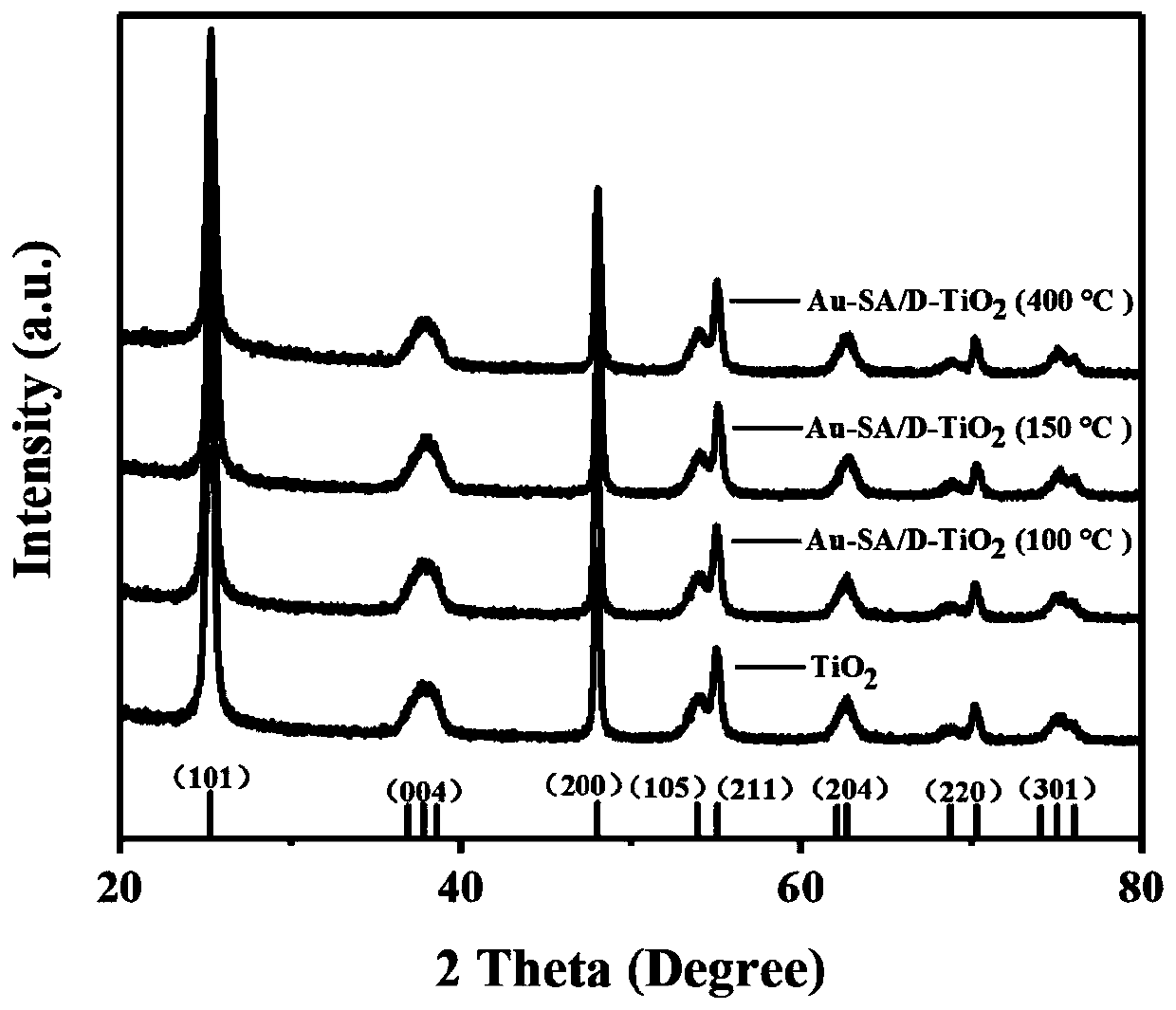

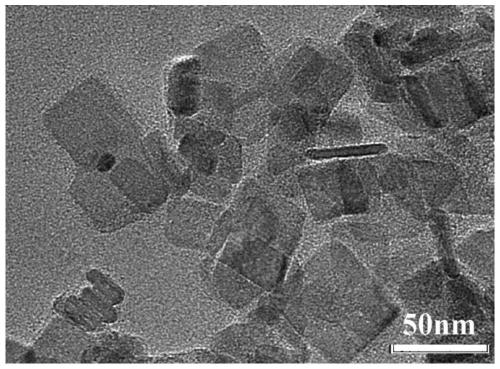

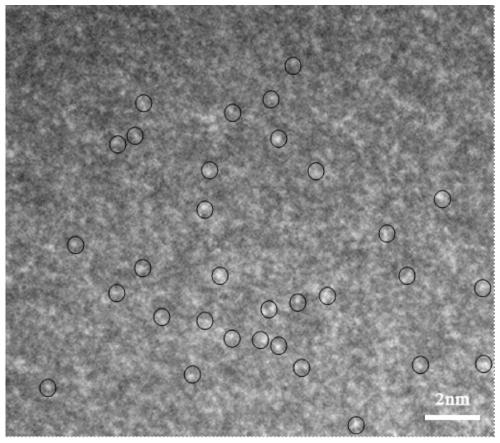

[0058] This embodiment provides a gold single-atom catalyst Au / TiO 2 , and its preparation method includes the following steps.

[0059] Synthesis of Au / TiO by Deposition-Precipitation Method 2 , specifically as follows: Weigh 1g of titanium dioxide nanosheets at a temperature of 100 ° C, calcined in argon and hydrogen (10vol.%) mixed gas, then suspend in 50mL deionized water, stir for 15 minutes, add ammonium carbonate solution (25mL, 1mol / L), tetrachloroauric acid trihydrate (10mg) were dissolved in 25mL deionized water, and dropped into the stock solution, the pH was 8.9. After stirring at room temperature for 1 hour, it was filtered, washed with water and ethanol, and the precipitate was collected and dried at 70° C. for 4 hours.

[0060] The obtained precursor was then calcined to 200 °C in a mixed gas of argon and hydrogen (10 vol.%), kept for two hours, and then the temperature was programmatically cooled to room temperature to obtain the gold single-atom catalyst Au / ...

Embodiment 2

[0062] This embodiment provides a gold single-atom catalyst Au / TiO 2 , and its preparation method includes the following steps.

[0063] Synthesis of Au / TiO by Deposition-Precipitation Method 2 , specifically as follows: Weigh 1g of titanium dioxide nanosheets at a temperature of 150 ° C, calcined in argon and hydrogen (10vol.%) mixed gas, then suspend in 50mL deionized water, stir for 15 minutes, add ammonium carbonate solution (25mL, 1mol / L), tetrachloroauric acid trihydrate (8mg) was dissolved in 25mL deionized water, and dropped into the stock solution, the pH was 9.17. After stirring at room temperature for 1 hour, it was filtered, washed with water and ethanol, and the precipitate was collected and dried at 70° C. for 4 hours.

[0064] The obtained precursor was then calcined to 200 °C in a mixed gas of argon and hydrogen (10 vol.%), kept for two hours, and then the temperature was programmatically cooled to room temperature to obtain the gold single-atom catalyst Au / T...

Embodiment 3

[0066] This embodiment provides a gold single-atom catalyst Au / TiO 2 , and its preparation method includes the following steps.

[0067] Synthesis of Au / TiO by Deposition-Precipitation Method 2 . Weigh 1g of titanium dioxide nanosheets at a temperature of 400 ° C, calcined in argon and hydrogen (10vol.%) mixed gas, then suspended in 50mL deionized water, after stirring for 15 minutes, add ammonium carbonate solution (25mL, 1mol / L), tetrachloroauric acid trihydrate (6mg) were dissolved in 25mL deionized water, and dropped into the stock solution, the pH was 9.05. After stirring at room temperature for 1 hour, it was filtered, washed with water and ethanol, and the precipitate was collected and dried at 70° C. for 4 hours.

[0068] The obtained precursor was then calcined to 200 °C in a mixed gas of argon and hydrogen (10 vol.%), kept for two hours, and then the temperature was programmatically cooled to room temperature to obtain the gold single-atom catalyst Au / TiO support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com