Aerobic granular sludge culture method and culture device

A technology of aerobic granular sludge and cultivation method, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. Unable to meet the standard and other problems, to achieve the effect of shortening the cultivation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

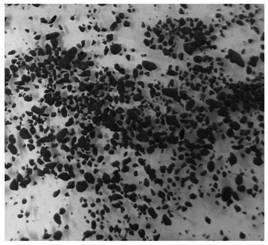

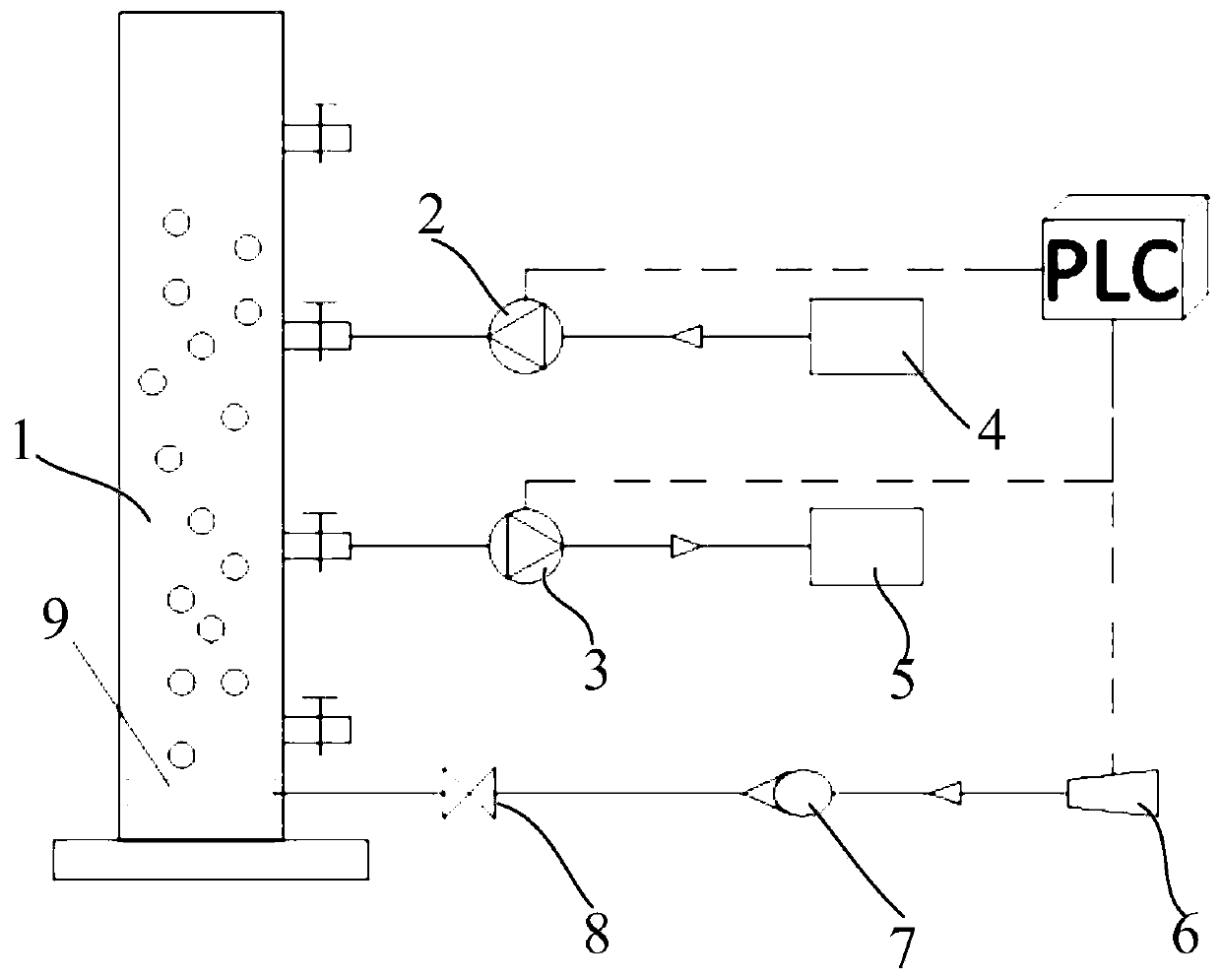

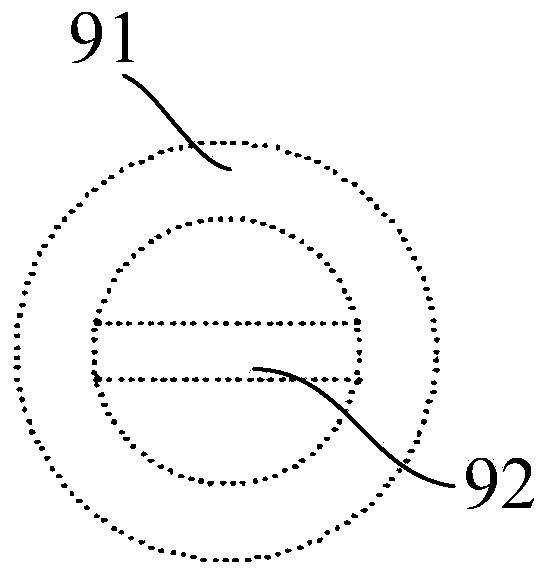

[0043]The mud cake after dehydration treatment in the sewage treatment plant is used as the inoculation sludge. The mud cake is yellowish brown, with a water content of 80%. After compression, the mud cake has a compact structure; the wastewater is taken from the sewage treatment plant regulating tank, and the COD of the wastewater is 500mg / L, total nitrogen 60mg / L, total phosphorus 6mg / L, suspended solids concentration 200mg / L, pH value 7.8, reactor height 1000mm, inner diameter 90mm, effective volume 3L, put inoculated sludge into the reactor Feed waste water into the reactor at the middle and back, air aerate for 24 hours, and then the reactor operates in the order of water intake-aeration-sedimentation-drainage, divided into 4 operation cycles every day, and each cycle runs for 6 hours. day, the water intake time is 6min, the aeration time is 337min, the aeration rate is 2L / min, the sedimentation time is 15min, the drainage time is 2min, and the water exchange rate is 50%....

Embodiment 2

[0047] The mud cake after dehydration treatment in the sewage treatment plant is used as the inoculation sludge. The mud cake is yellowish brown, with a water content of 85%. After compression, the mud cake has a compact structure; the waste water is taken from the sewage treatment plant regulating tank, and the COD of the waste water is 490mg / L, total nitrogen 62mg / L, total phosphorus 6mg / L, suspended solids concentration 320mg / L, pH value 8.2, reactor height 1000mm, inner diameter 90mm, effective volume 3L, put inoculated sludge into the reactor Feed waste water into the reactor in the middle and back, air-aerate for 22 hours, and then the reactor operates in the order of water intake-aeration-sedimentation-drainage, with 4 operating cycles per day. On the first to seventh days, the water intake time is 5min, the aeration time is 337min, the aeration rate is 5L / min, the settling time is 15min, the drainage time is 3min, and the water exchange rate is 50%. On the 7th day, aer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com