Adsorption crystallization coupling aromatic hydrocarbon production method and system provided with toluene shape-selective disproportionation

A technology of crystallization and toluene, applied in the field of adsorption crystallization coupling aromatics production system, can solve the problems of adsorption separation process limitations, no further progress, low heat utilization efficiency, etc., and achieve the effect of avoiding continuous accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

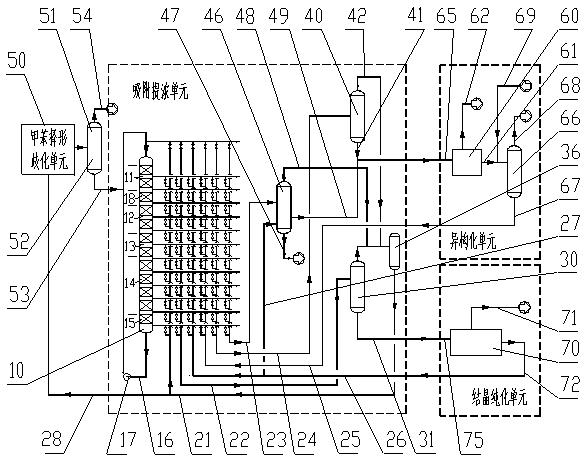

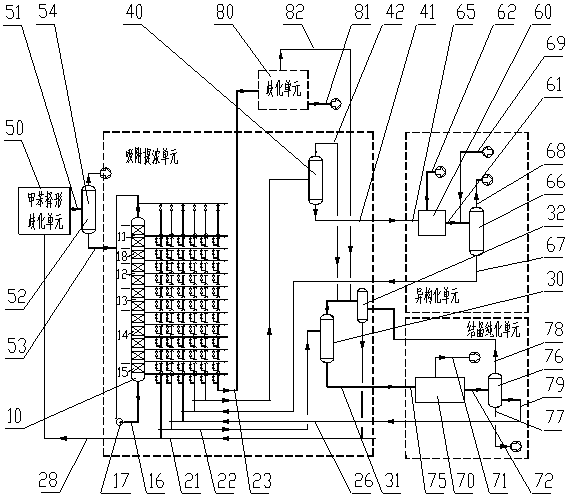

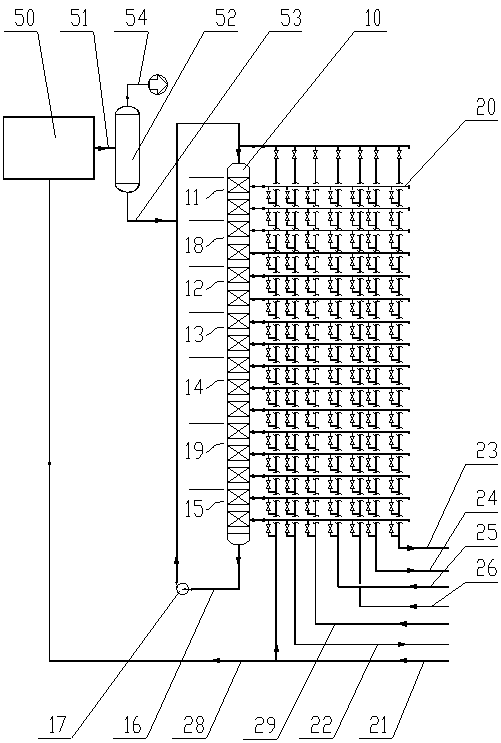

[0103] see Figure 1~6 , the adsorption crystallization coupled aromatics production system provided with toluene shape-selective disproportionation of the present invention is used to implement any one of the adsorption crystallization coupled aromatics production methods provided with toluene shape-selective disproportionation disclosed in the present invention, by adopting any one disclosed in the present invention An adsorption crystallization coupled aromatics production method with toluene shape-selective disproportionation is provided for aromatics production.

[0104] The system mainly includes an adsorption concentration unit, an isomerization unit, a crystallization purification unit and a toluene shape-selective disproportionation unit.

[0105] The simulated moving bed 10 of the adsorption and concentration unit is used for the adsorption and concentration of PX, and is successively divided into an adsorption zone, a refining zone 12, a desorption zone and an isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com