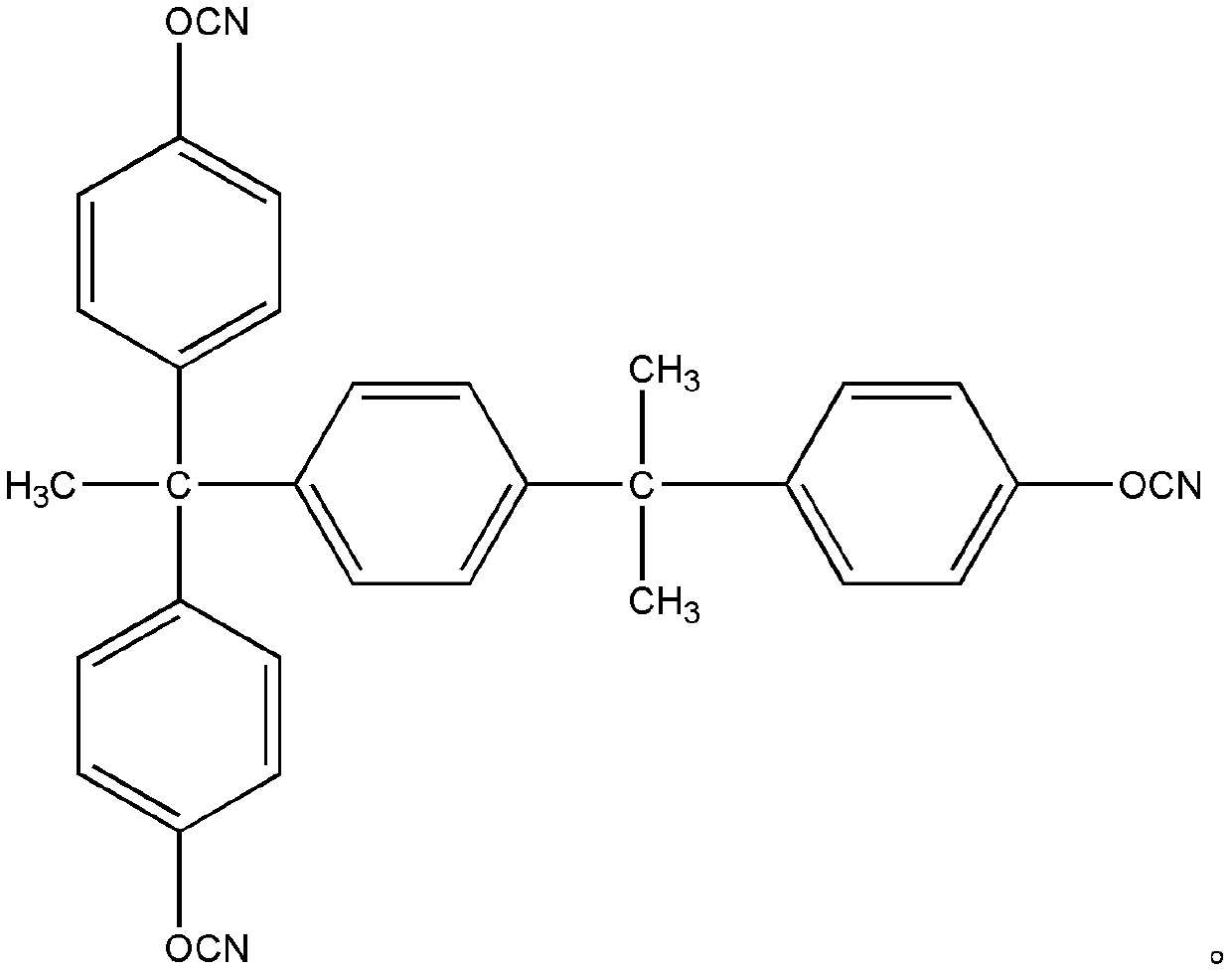

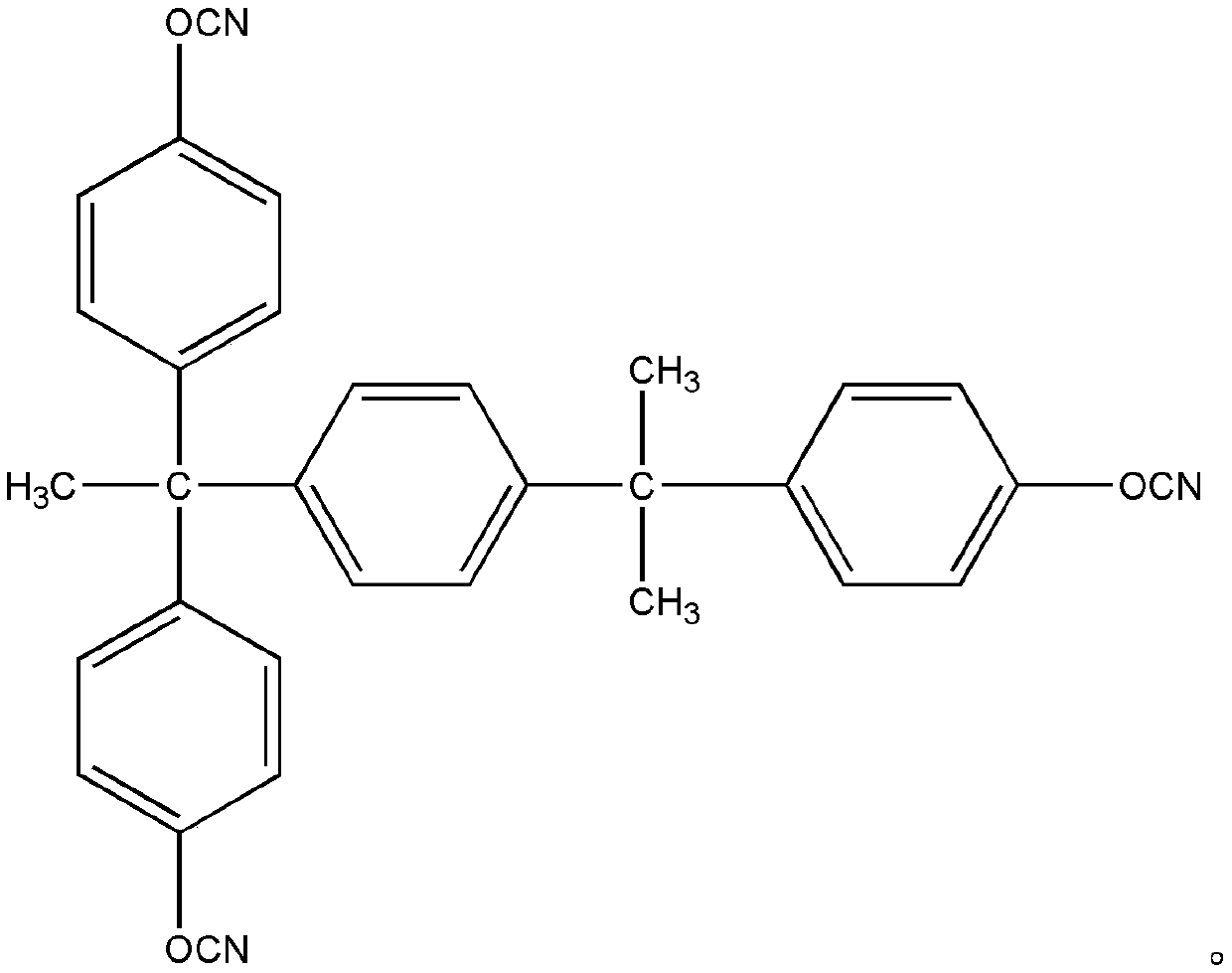

Triphenol A type cyanate ester and preparation method thereof

A type of cyanate ester and triethylamine technology, which is applied in the field of organic polymer material synthesis, can solve the problems of moisture absorption and heat resistance, and achieve good manufacturability and repeatability, stable yield and quality, and Effect of heat and humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] A preparation method of trisphenol A type cyanate, in a 3000ml four-necked flask equipped with a stirrer, dropping funnel and thermometer, first put 2600g of ether into it, cool to -5°C, and then add 400g of cyanogen chloride.

[0020] Dissolve 600g of triphenol A in 2600g of ether, then add 500g of triethylamine and stir evenly. Control the reaction temperature at 0°C, add the above mixed solution dropwise to the ether solution of cyanogen chloride, and add dropwise for 1 hour. After the dropwise addition is complete, continue to keep warm for 1 hour.

[0021] Pour the reaction materials into a beaker, add 2500ml of deionized water, 2000ml of alkaline water, 1600ml of acidic water, and 2000ml of deionized water*2 in sequence, and repeat the steps of washing, resting, layering, and collecting the feed solution.

[0022] Add 200 g of anhydrous sodium sulfate to the collected feed liquid, filter and collect the feed liquid, add it to a 3000ml four-neck flask, carry out ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com