Condensed polycyclic compound, preparation method and application thereof

A technology for fused polycyclic compounds, which is applied in the field of fused polycyclic compounds and their preparation, can solve the problems of easy crystallization, low glass transition temperature, inability to have both thermal stability and high triplet energy level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

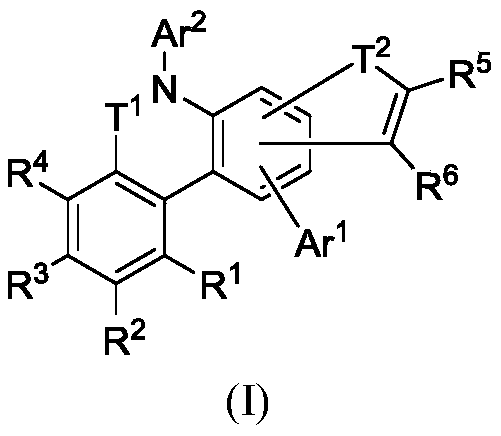

Method used

Image

Examples

Embodiment 1

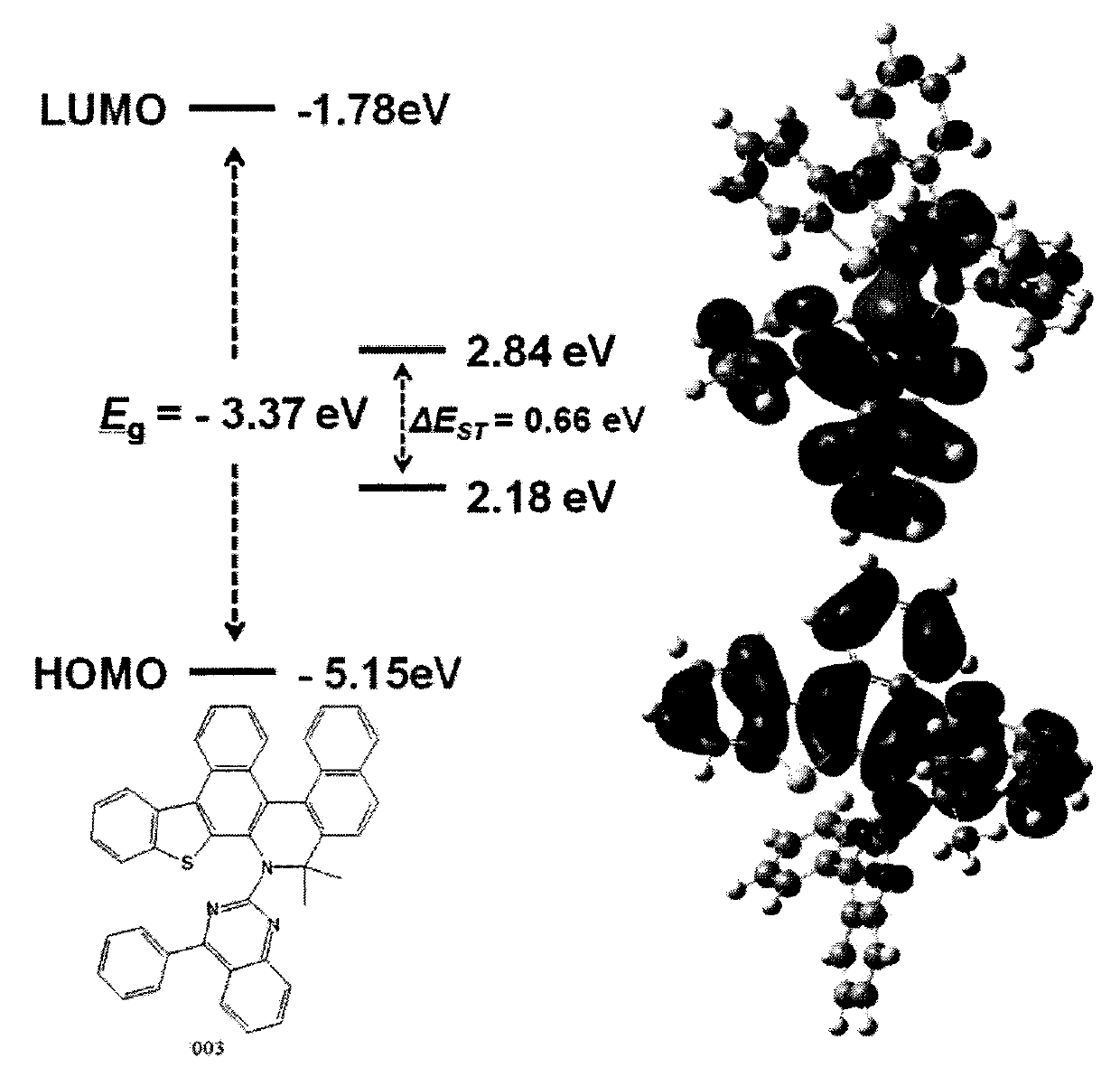

[0091] This embodiment provides a fused polycyclic compound having the structure shown in the following formula 003:

[0092]

[0093] The synthetic route of the compound shown in formula 003 is as follows:

[0094]

[0095] The preparation method of the compound shown in formula 003 specifically comprises the following steps:

[0096] (1) Preparation of intermediate 003-B

[0097] Add 500mL of acetic acid in the there-necked flask, then add 72.0g (0.20mol) of the compound shown in formula 003-A, add 20.3g (0.21mol) of concentrated nitric acid with a mass fraction of 65% dropwise at 0°C, after the addition is complete, the Stir at ℃ for 2 hours, pour the reaction solution into 800 mL of ice water, add sodium hydroxide to neutralize the solution to a pH of 6-7, extract twice with 500 mL of ethyl acetate, combine the organic phases, and wash the organic phases with 200 mL of saturated brine for 2 After drying with anhydrous sodium sulfate, the dried organic phase was spi...

Embodiment 2

[0108] This embodiment provides a fused polycyclic compound having the structure shown in the following formula 001:

[0109]

[0110] The difference between the preparation steps of the compound shown in formula 001 and the preparation steps of the compound shown in 003 provided in Example 1 is only:

[0111] The compound represented by formula 003-C-1 was used to replace the compound 003-C in the step (2) of Example 1, and the total yield of the compound represented by the structure represented by 001 was 25.7%.

[0112]

Embodiment 3

[0114] This embodiment provides a fused polycyclic compound having the structure shown in the following formula 002:

[0115]

[0116] The difference between the preparation steps of the compound shown in formula 002 and the preparation steps of the compound shown in 003 provided in Example 1 is only:

[0117] The compound represented by formula 003-C-2 was used to replace the compound 003-C in the step (2) of Example 1, and the total yield of the compound represented by the structure represented by 002 was 24.9%.

[0118]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com