Method for preparing cement kiln fuel from lignite and biomass co-pyrolysis product

A technology for pyrolysis products and biomass, which can be applied to biofuels, waste fuels, fuels, etc., can solve the problems of low calorific value of lignite, and the difficulty of lignite calorific value to meet the combustion temperature, so as to improve energy utilization, low cost and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

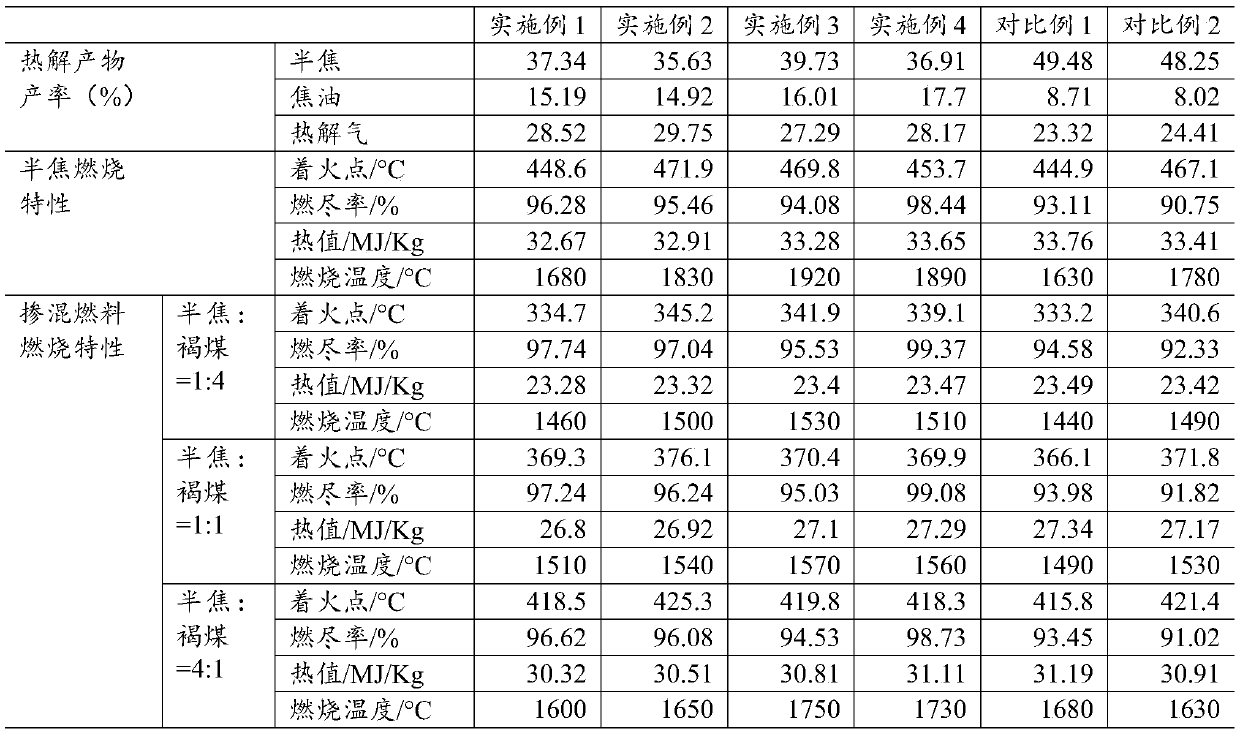

Embodiment 1

[0024] The dried pine sawdust and lignite were pulverized and sieved respectively to obtain a 50-200 mesh sample, and the pine sawdust sample and the lignite sample were mixed uniformly at a mass ratio of 3:7 to obtain a mixed sample with a total mass of 10 g. Then put the mixed sample in a pyrolysis furnace for airtight anaerobic pyrolysis. The heating rate of the pyrolysis process is 10°C / min, the constant temperature of pyrolysis is 400°C, and the pyrolysis time at constant temperature is 30min. After pyrolysis, the pyrolysis gas is condensed by a circulating condensing device, and the hydrous pyrolysis tar is separated. The hydrolysis pyrolysis tar is dehydrated to obtain pyrolysis tar. The condensed pyrolysis gas is collected and sealed with a gas collection bag. The pyrolysis furnace The remaining solid product is pyrolysis semi-coke, and finally the pyrolysis semi-coke and lignite are mechanically mixed at a mass ratio of 1:4, 1:1, and 4:1 respectively to obtain fuel.

Embodiment 2

[0026] The dried pine sawdust and lignite were pulverized and sieved respectively to obtain a 50-200 mesh sample, and the pine sawdust sample and the lignite sample were mixed uniformly at a mass ratio of 4:6 to obtain a mixed sample with a total mass of 10 g. Then put the mixed sample in a pyrolysis furnace for airtight anaerobic pyrolysis. The heating rate of the pyrolysis process is 20°C / min, the constant temperature of pyrolysis is 450°C, and the pyrolysis time at constant temperature is 30min. After pyrolysis, the pyrolysis gas is condensed by a circulating condensing device, and the hydrous pyrolysis tar is separated. The hydrolysis pyrolysis tar is dehydrated to obtain pyrolysis tar. The condensed pyrolysis gas is collected and sealed with a gas collection bag. The pyrolysis furnace The remaining solid product is pyrolysis semi-coke, and finally the pyrolysis semi-coke and lignite are mechanically mixed at a mass ratio of 1:4, 1:1, and 4:1 respectively to obtain fuel.

Embodiment 3

[0028] The dried pine sawdust and lignite were pulverized and sieved respectively to obtain a 50-200 mesh sample, and the pine sawdust sample and the lignite sample were mixed uniformly at a mass ratio of 3:7 to obtain a mixed sample with a total mass of 10 g. Then put the mixed sample in a pyrolysis furnace for airtight anaerobic pyrolysis. The heating rate of the pyrolysis process is 10°C / min, the constant temperature of pyrolysis is 450°C, and the pyrolysis time at constant temperature is 30min. After pyrolysis, the pyrolysis gas is condensed by a circulating condensing device, and the hydrous pyrolysis tar is separated. The hydrolysis pyrolysis tar is dehydrated to obtain pyrolysis tar. The condensed pyrolysis gas is collected and sealed with a gas collection bag. The pyrolysis furnace The remaining solid product is pyrolysis semi-coke, and finally the pyrolysis semi-coke and lignite are mechanically mixed at a mass ratio of 1:4, 1:1, and 4:1 respectively to obtain fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com