Ultra-large-load water-cooling low-NOx gas burner

A gas burner, water cooling technology, applied in gas fuel burners, burners, combustion methods, etc., can solve the problems of short service life of heating furnaces and achieve the effect of inhibiting NOx generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

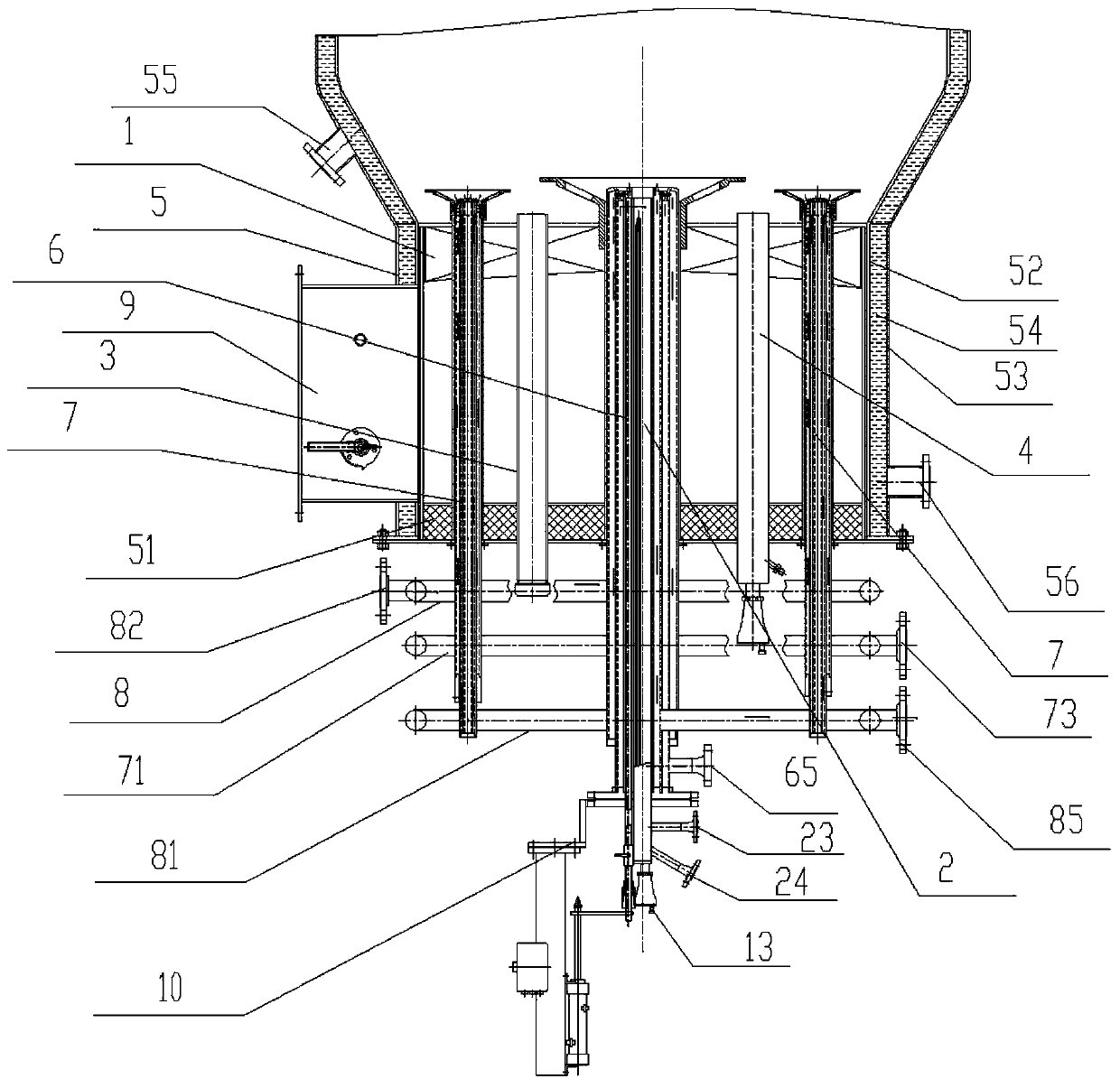

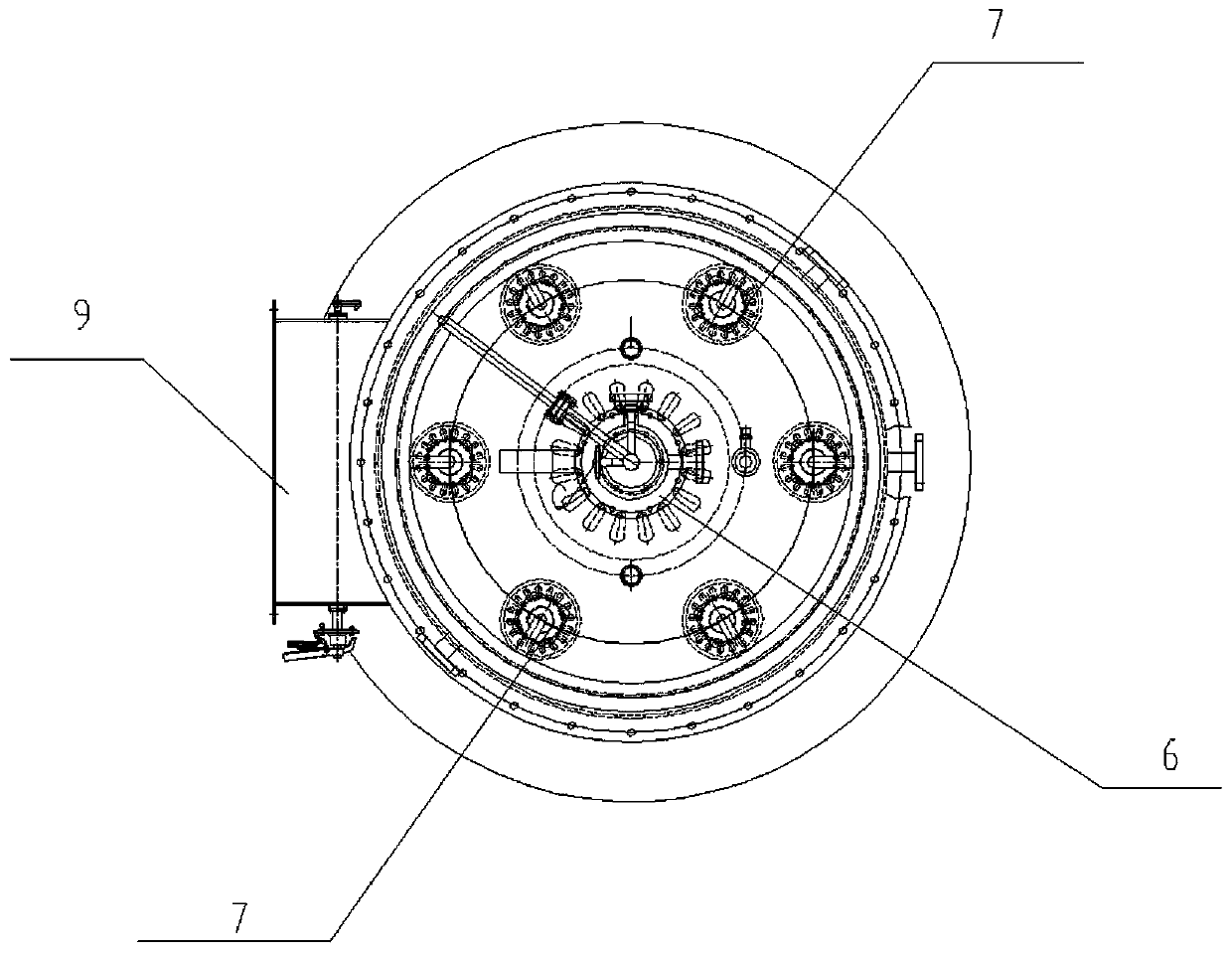

[0040] see Figure 1 to Figure 9 , a super load water cooled low NO x The gas burner is installed in the heating furnace, including the high-pressure cooling water circulation assembly, the swirl plate assembly 1, the light assembly 2, the burner cylinder assembly 5 and the burner cylinder assembly through the bottom of the burner cylinder assembly 5 Central gas gun assembly 6, annular gas gun assembly 7, viewing fire hole assembly 3, fire detection assembly 4 in 5.

[0041] Wherein, the permanent light assembly 2 extends into the central gas gun assembly 6 from the bottom of the central gas gun assembly 6 and is fixed at the center of the central gas gun assembly 6 . The swirl vane assembly 1 is arranged in the combustor barrel assembly 5 .

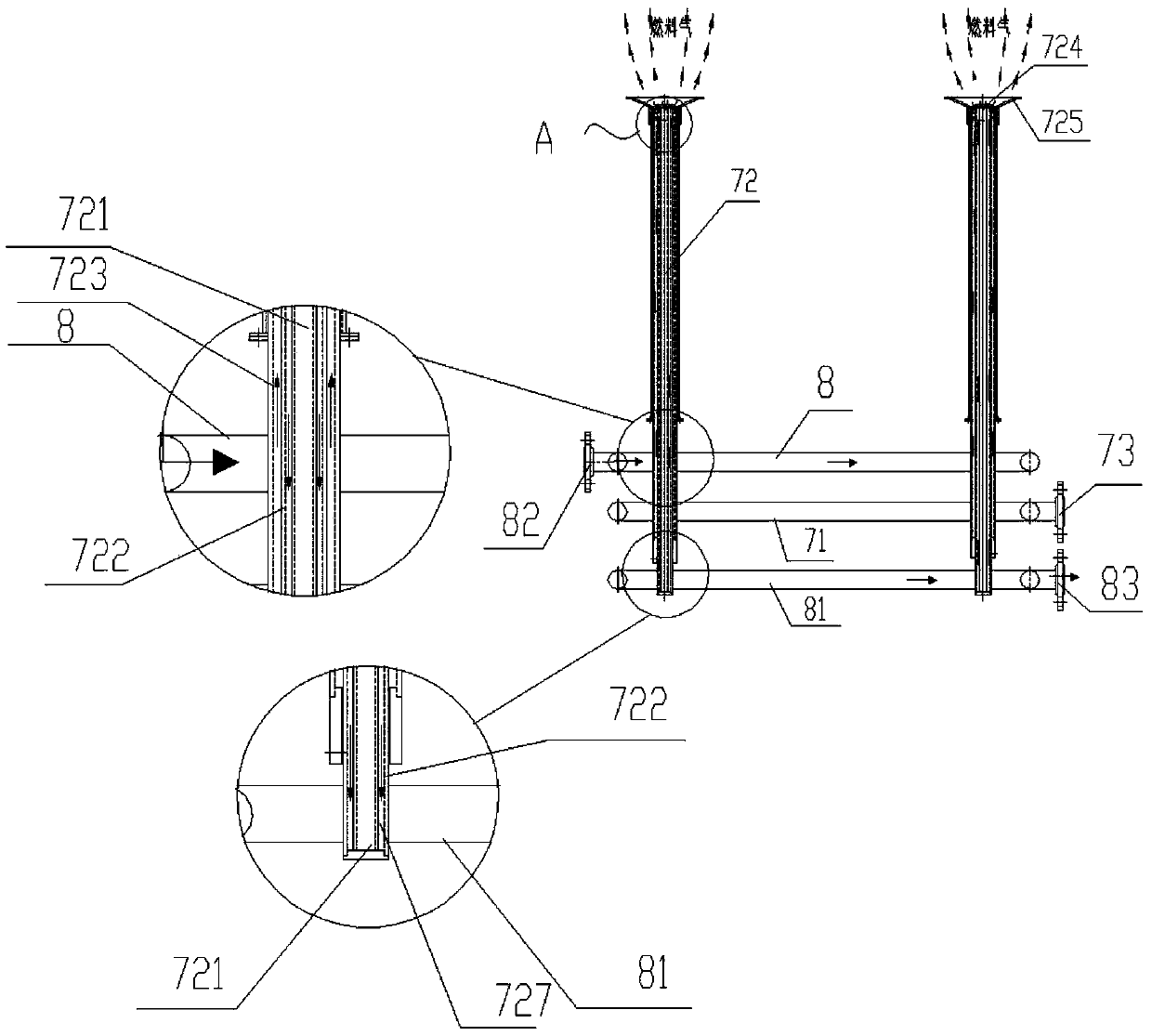

[0042] Among them, the high-pressure cooling water circulation assembly includes a cooling water inlet pipe 8, a cooling water outlet pipe 81, a gas gun cooling water inlet 82, a gas gun cooling water outlet 83, a cylinder cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com