MOF-based porous polyaniline electrode material, preparation method thereof and use thereof

An electrode material, polyaniline technology, applied in the field of porous polyaniline electrode materials and its preparation, can solve the problems of poor electrical conductivity, etc., and achieve the effects of good electrical conductivity, large specific surface area, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a MOF-based porous polyaniline electrode material, comprising:

[0024] (1) 0.7248g Cu(NO 3 ) 2 ·3H 2 O was dissolved in 12mL ultrapure water and stirred evenly;

[0025] (2) Add 0.4203g H 3 BTC (trimesic acid) was dissolved in 12mL of absolute ethanol and stirred for 0.5h;

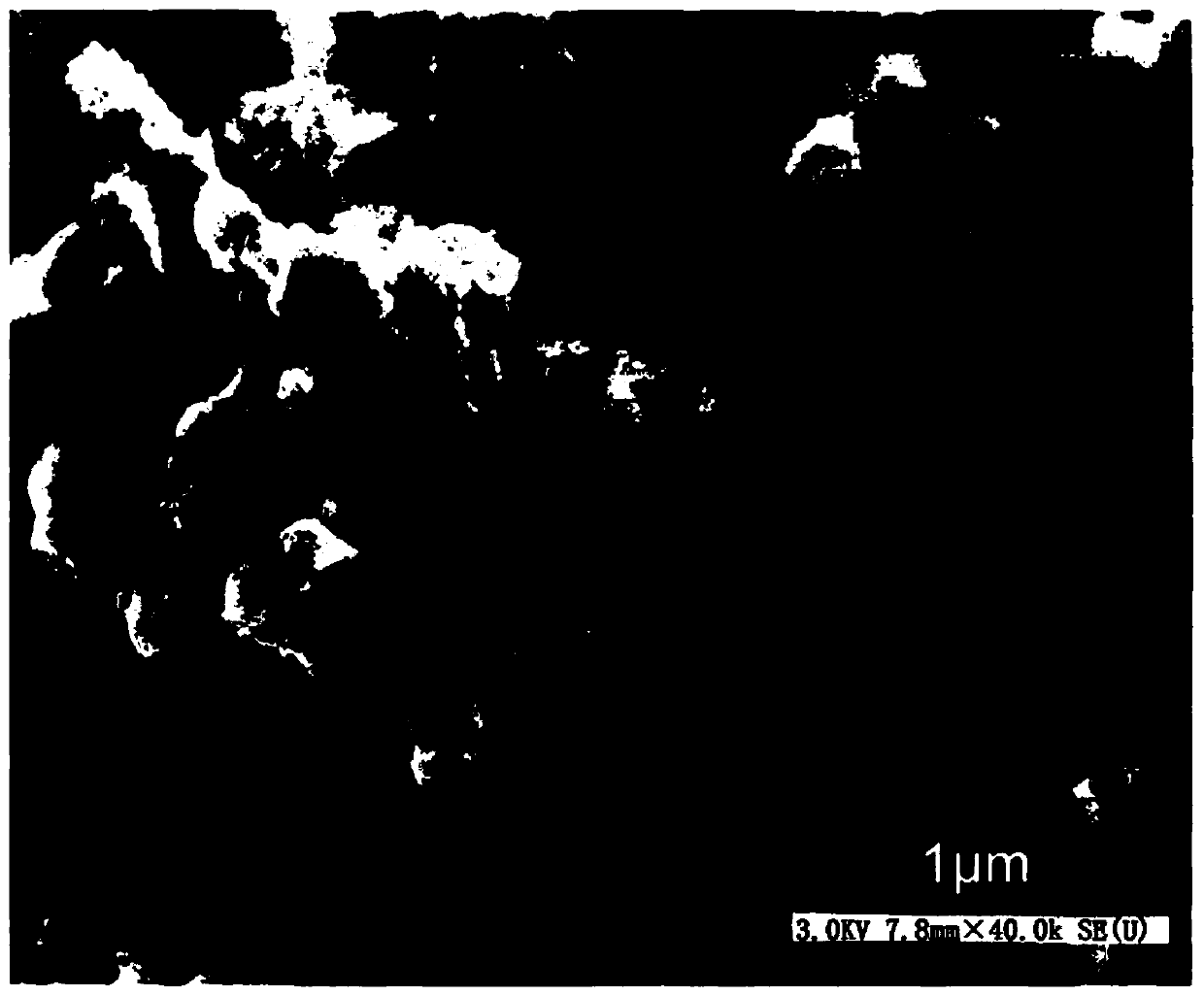

[0026] (3) Mix and stir the solutions prepared in step (1) and step (2), then seal the mixture in an autoclave, heat to 110° C. for 12 hours and then centrifuge the precipitate, place the precipitate in ethanol and Cool to room temperature, centrifuge and dry in air at room temperature to obtain a blue 3,3,5-C polyhedral metal-organic framework;

[0027] (4) Disperse acetylene black (conductive agent), PVDF (polyvinylidene fluoride, binder) and 3,3,5-C polyhedral metal-organic framework in N,N-dimethylformamide (DMF) , with a mass ratio of 7:2:1, prepared into a slurry after stirring for 6 hours;

[0028] (5) Coat the prepared slurry evenly on the carbon fiber cloth (C...

Embodiment 2

[0032] The preparation method of the porous polyaniline electrode material based on MOF is basically the same as that of Example 1, the difference is that:

[0033] In step (1), Cu(NO 3 ) 2 ·3H 2 The consumption of O is 2.1744g, and the consumption of ultrapure water is 36mL;

[0034] In step (2), H 3 The dosage of BTC is 1.2609g, the dosage of absolute ethanol is 36mL, stir for 1h;

[0035] In step (3), heating to 130° C. for 15 hours;

[0036] In step (4), the mass ratio of acetylene black (conductive agent), PVDF (polyvinylidene fluoride, binder) and 3,3,5-C polyhedral metal-organic framework is 9:4:1, after stirring for 8 hours prepared as a slurry;

[0037] In step (6), H 2 SO 4 In a solution with a concentration of 1.5 mol / L and a concentration of ANI of 0.3 mol / L, the duty ratio of the applied positive pulse is 60%, and the deposition lasts for 400 s.

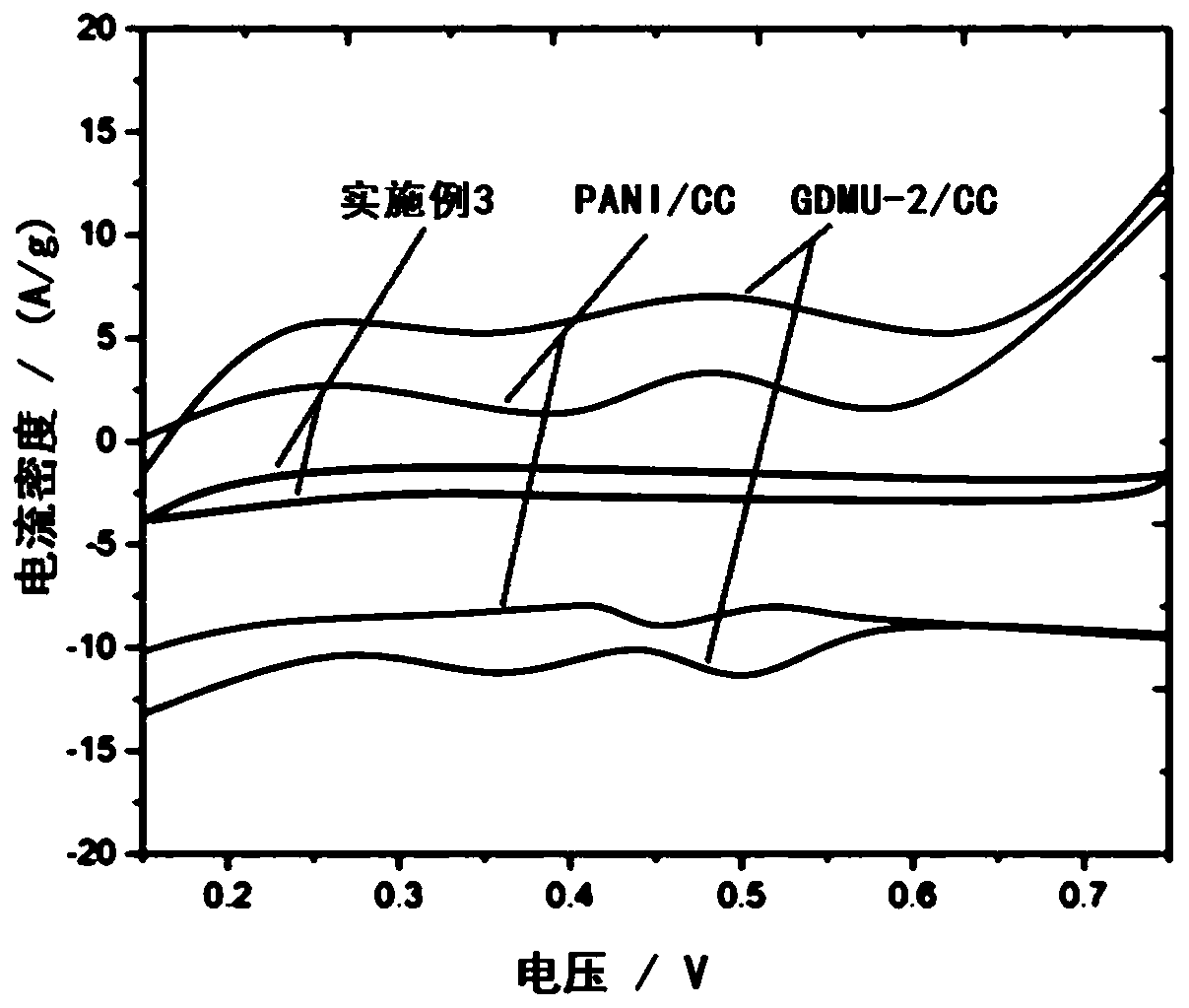

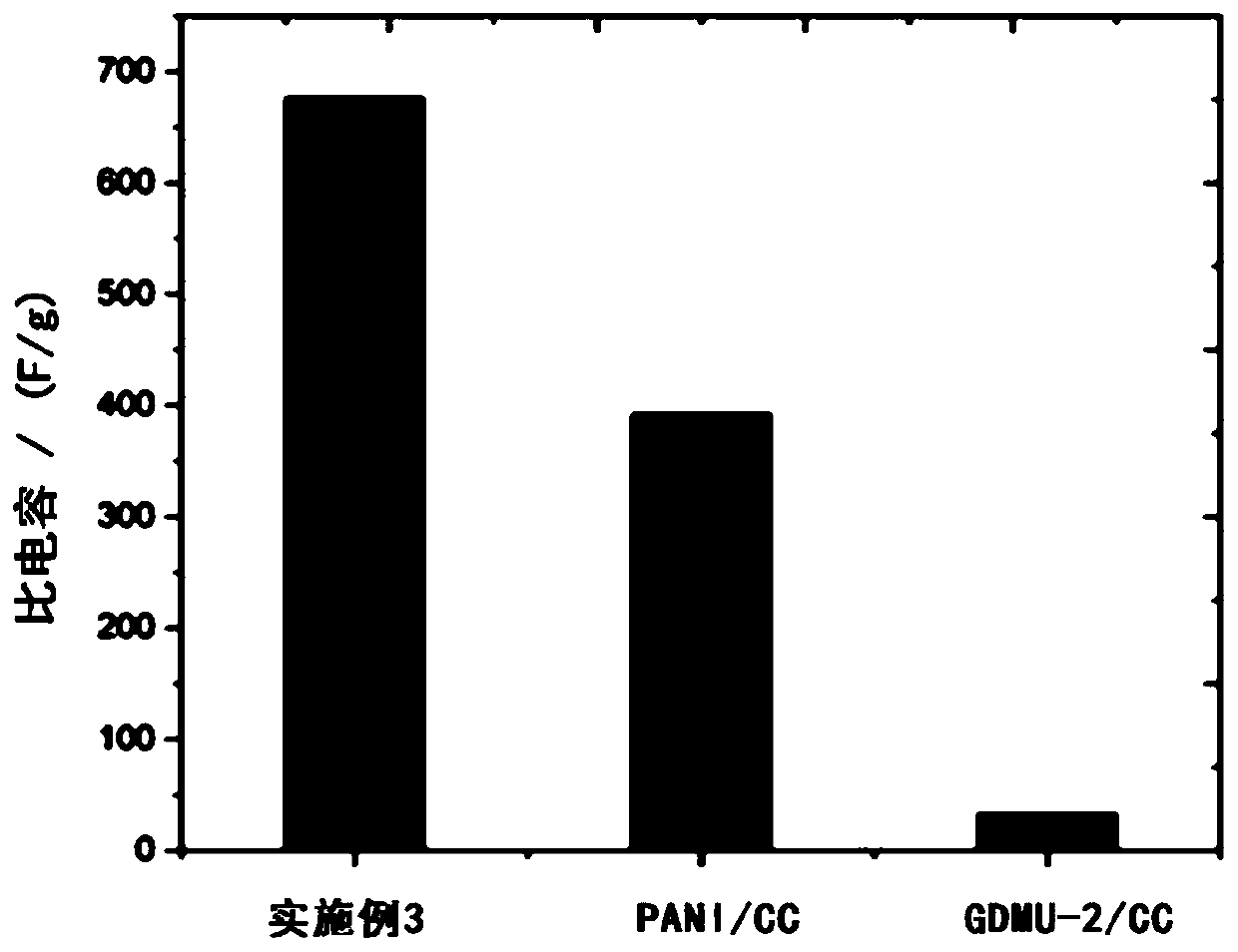

Embodiment 3

[0039] The preparation method of the porous polyaniline electrode material based on MOF is basically the same as that of Example 1, the difference is that:

[0040] In step (1), Cu(NO 3 ) 2 ·3H 2 The consumption of O is 1.4496g, and the consumption of ultrapure water is 24mL;

[0041] In step (2), H 3 The dosage of BTC is 0.8406g, the dosage of absolute ethanol is 24mL, stir for 1h;

[0042] In step (3), heating to 120° C. for 13 hours;

[0043] In step (4), the mass ratio of acetylene black (conductive agent), PVDF (polyvinylidene fluoride, binder) and 3,3,5-C polyhedral metal-organic framework is 8:3:1, after stirring for 7 hours prepared as a slurry;

[0044] In step (6), H 2 SO 4 In a solution with a concentration of 1.0 mol / L and a concentration of ANI of 0.2 mol / L, the duty ratio of the applied positive pulse is 55%, and the deposition lasts for 350 s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com