Carbon-composited sulfur compound composite material and preparation method and application thereof

A technology of chalcogenides and composite materials, which is applied in the fields of nanotechnology, electrochemical generators, electrical components, etc. for materials and surface science, which can solve the problem of low chalcogenide loading, difficult industrial application, and carbon-based composite materials. Structural stability can not meet the requirements and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a carbon-composite chalcogenide composite material described in the above technical solution, comprising the following steps:

[0037] After mixing metal powder and / or silicon powder with chalcogenide material and carbon material, mechanical alloying is carried out to obtain a carbon-composite chalcogenide compound material; the chalcogenide material is at least one of sulfur powder and selenium powder.

[0038] In the present invention, the metal powder and / or silicon powder refers to: a mixture of metal powder and silicon powder, metal powder, and silicon powder; specifically, when the chalcogenide is a metal chalcogenide, the Metal powder is mixed with chalcogenide materials and carbon materials, when the chalcogenides are silicon chalcogenides (such as SiS 2 、SiSe 2 ), the silicon powder is mixed with the chalcogenide material and the carbon material, and when the chalcogenide compound is a mixture of metal...

Embodiment 1

[0050] Put 0.933g iron powder (purity>99.95%), 1.067g sulfur powder (purity>99.9%), 0.1g multi-walled carbon nanotubes (purity>95%, diameter less than 8nm, length 10-30μm) in the glove box After the argon atmosphere is manually ground and mixed evenly, it is put into a stainless steel ball mill jar, and a stainless steel ball with a diameter of 12mm is weighed according to the ratio of the ball to material ratio of 10:1, and added to the stainless steel ball mill jar, and the The ball milling tank is sealed, and ball milling is carried out at a speed of 500r / min for 35 hours to obtain a carbon-composite iron disulfide negative electrode material, which is denoted as FeS 2 @CNTs.

[0051] Characterization of the structure:

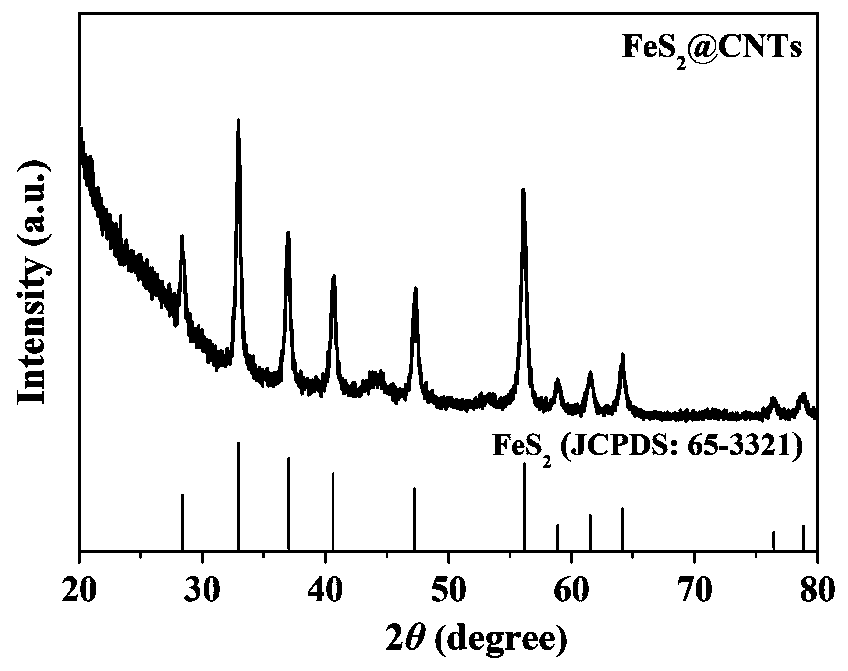

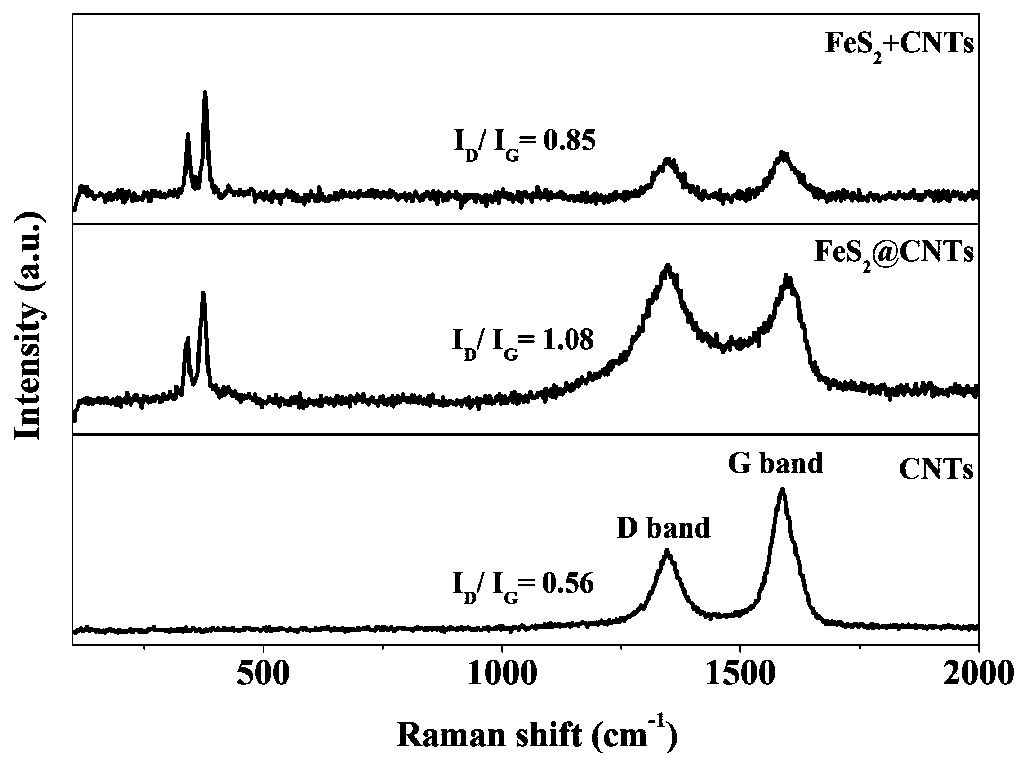

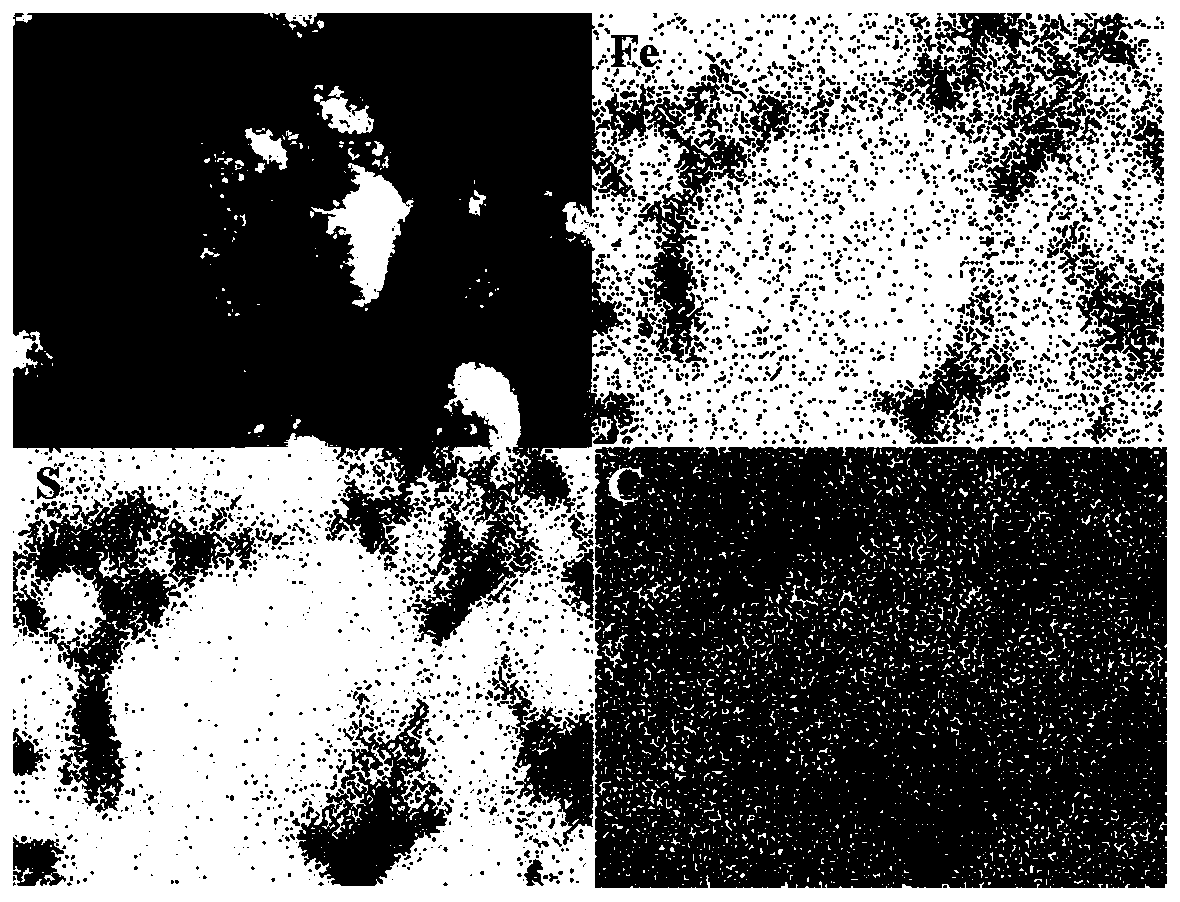

[0052] FeS 2 @CNTs conducts X-ray diffraction (XRD) test, the test uses Rigaku D / max-2500 / PC (Cu Kα, 40kV, 200mA), the test range is 10°~80°, the rate is 4 degrees / min, the results are as follows figure 1 shown. Depend on figure 1 It can be seen that F...

Embodiment 2

[0060] 0.933g iron powder (purity > 99.95%), 1.067g sulfur powder (purity > 99.9%), and 0.1g graphene were manually ground and mixed in the argon atmosphere in the glove box, and then put into a stainless steel ball mill tank, according to Weigh stainless steel balls with a diameter of 12mm at a ball-to-material ratio of 10:1, add them to a stainless steel ball mill jar, seal the ball mill jar in an argon atmosphere, and ball mill for 40 hours at a speed of 500r / min to obtain carbon-composite disulfide Iron anode material, denoted as FeS 2 @graphene.

[0061] Test the FeS obtained in this embodiment 2 The SEM image of @graphene, and measure its average particle size to be 50nm; use HRTEM to test the FeS obtained in this example 2 @graphene's TEM image, and measured FeS 2 The average particle size of the nanocrystals is 10 nm.

[0062] Adopt the testing method of electrochemical performance among the embodiment 1 to test FeS 2Electrochemical performance of @graphene with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com