Motor control module, actuator and electro-mechanical braking device

A technology of motor control and actuator, applied in the direction of motor control, connection with control/drive circuit, brake, etc., can solve the problems of low assembly efficiency, circuit board scrapping, circuit board occupation, etc., to improve assembly efficiency, Reduce the difficulty of assembly and meet the diverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

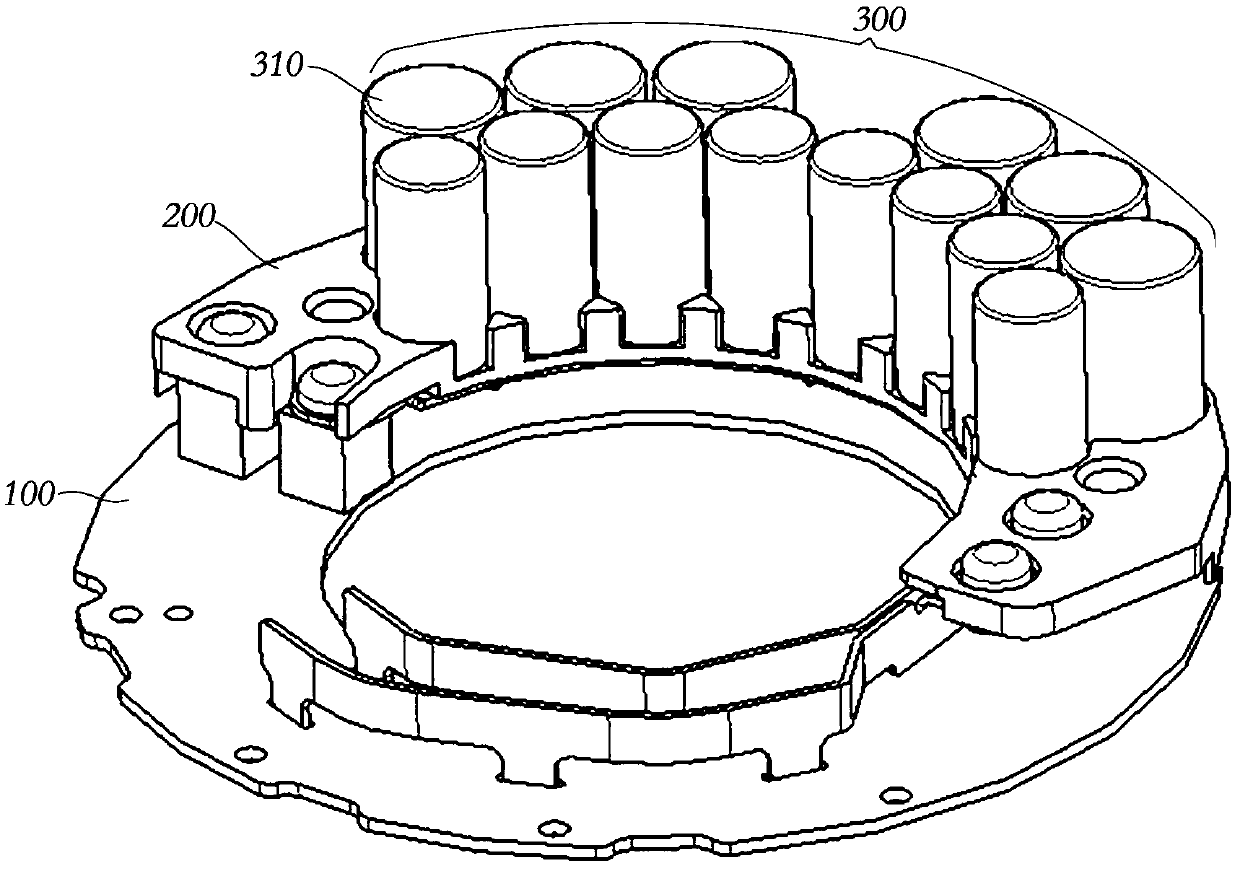

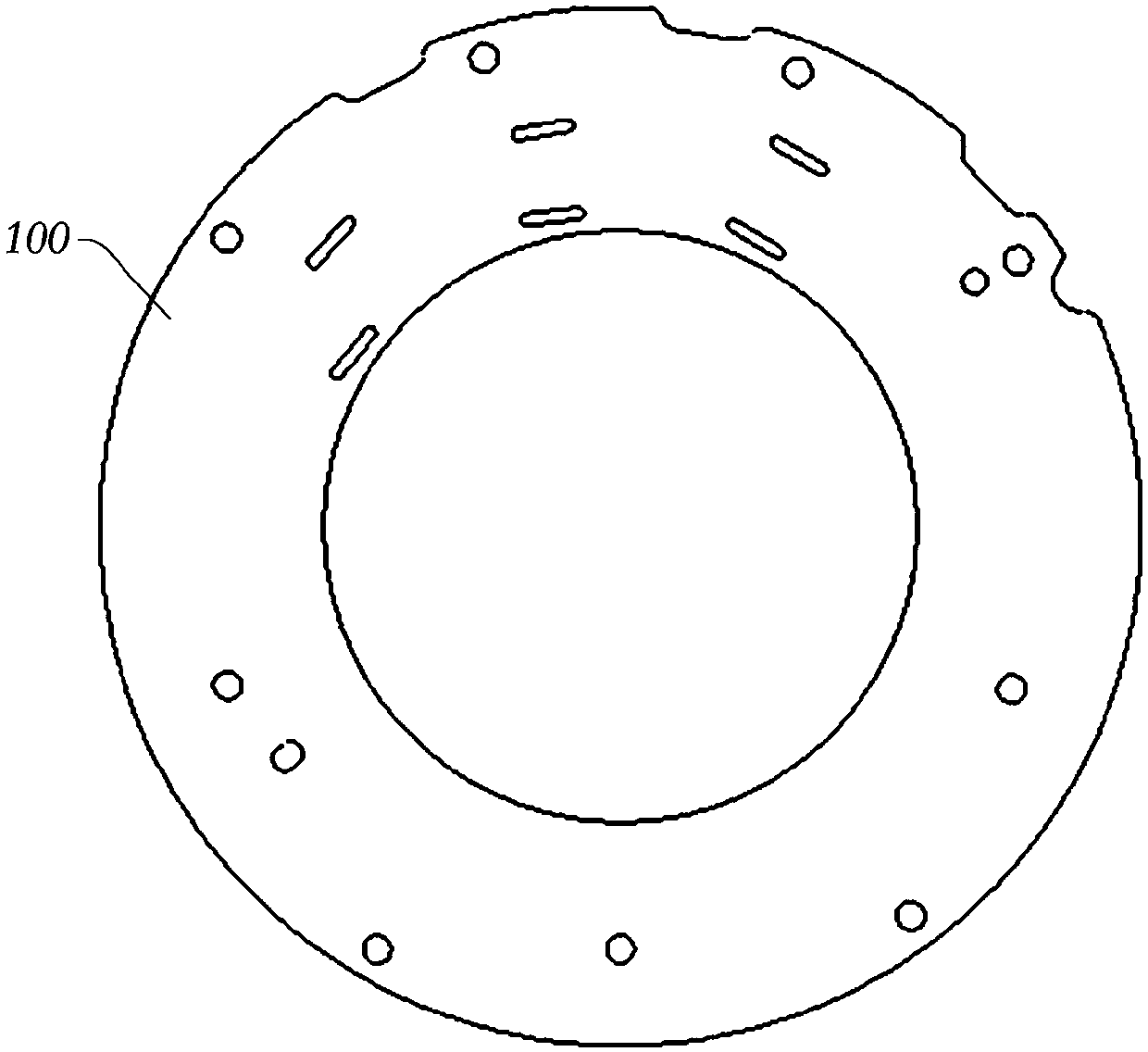

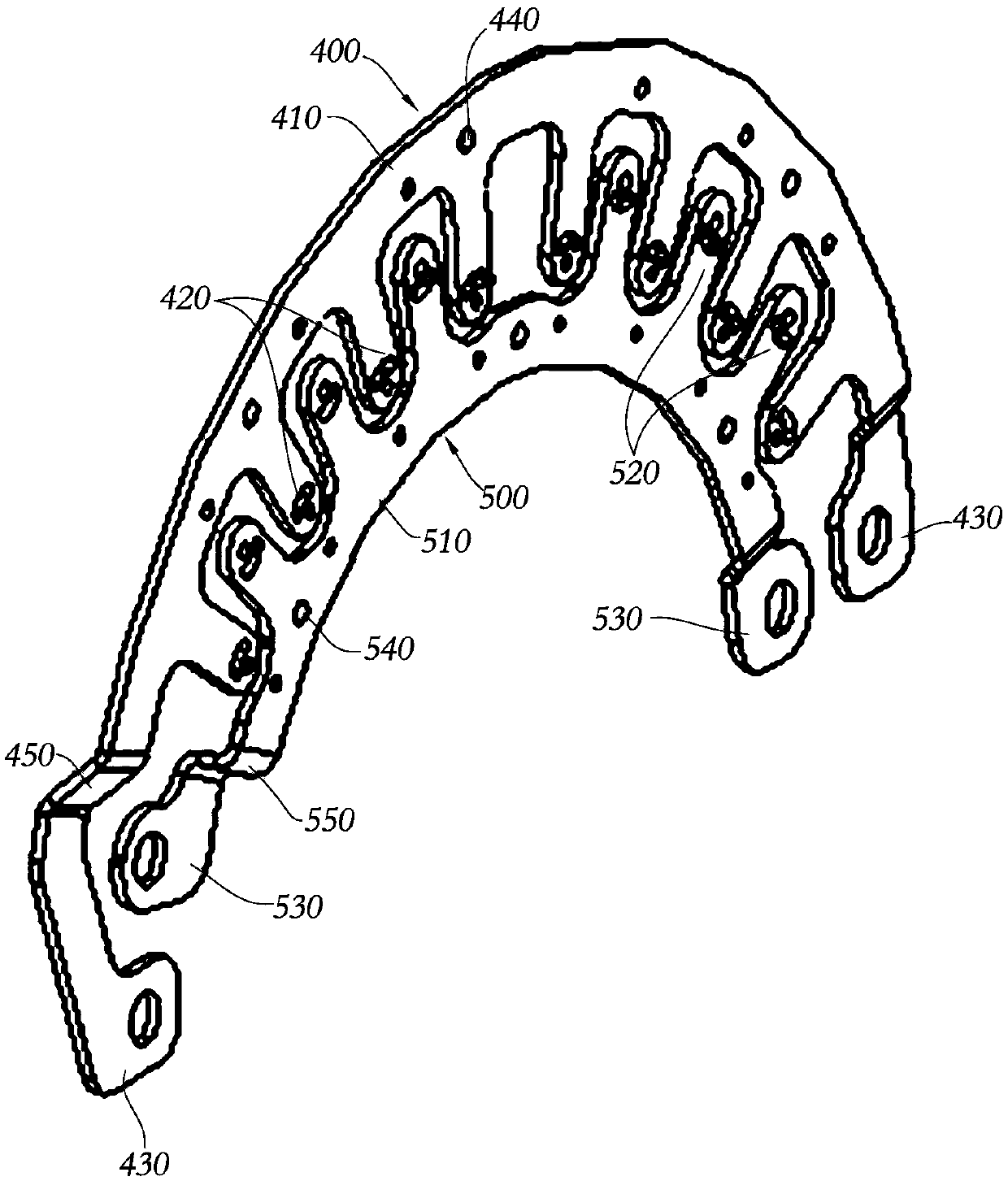

[0086] refer to figure 1 , the motor control module for the vehicle braking system proposed by the present invention includes: a circuit board 100, a capacitor group 300 and a conductive connector, wherein the capacitor group 300 includes a plurality of capacitors 310, and the plurality of capacitors 310 are respectively connected to the conductive The connecting piece forms a capacitor group 300 in which a plurality of capacitors 310 are electrically connected to each other through a conductive connecting piece. Keep a gap between. According to the purpose of the present invention: after the capacitor group 300 is connected to the circuit board 100 through a conductive connector, the capacitor group 300 and the circuit board 100 form a stacked structure. Except for the connection part with the circuit board 100, other parts of the conductive connector are relatively circuit The board 100 is in a suspended state, which enables the capacitor group 300 connected to the conducti...

Embodiment approach 2

[0109] The difference from Embodiment 1 is that in Embodiment 2, the capacitor bracket includes a first bracket and a second bracket formed separately, and the two ends of the body of the capacitor are respectively positioned on the first bracket and the second bracket, and the first bracket and the second bracket are respectively positioned. The structural design of the second bracket can refer to the capacitor bracket described in Embodiment 1. The capacitor is positioned according to the scheme described in Embodiment 1. Since the upper and lower ends of the capacitor are fixed by the bracket, the shaking of the capacitor can be better prevented. Better: the first bracket and the second bracket are fixedly connected to each other, such as screwed, to clamp and fix the capacitor group between the two, which can prevent the first bracket and the second bracket from being separated from each other, and the capacitor bracket can better position the capacitor Stablize.

[0110] ...

Embodiment approach 3

[0113] The difference from the first embodiment is that in the third embodiment, the motor control module further includes an extended connector, and the conductive connector and the circuit board are electrically connected through the extended connector. The expansion connector is not only used as an extension of the conductive connector, so that the conductive connector can be electrically connected to the connection point on the circuit board that is far away from the capacitor bank, but also can be used for the distribution of power transmission, and the electric energy of the capacitor bank is separately supplied to the circuit board. Other electronic components or circuits meet the power supply requirements of other components and circuits on the circuit board. For example, capacitor banks and conductive connectors are located in a specific area of the circuit board. The electrical connection of electronic components and circuits to other areas of the circuit board.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com