Automatic machining equipment for electrode net arranged in medical plasma sterilizer

A plasma and automatic processing technology, used in metal processing equipment, perforation tools, manufacturing tools, etc., can solve the problems of increasing equipment footprint, low processing efficiency, increasing worker workload, etc., and reducing equipment footprint , Improve processing efficiency and reduce the effect of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

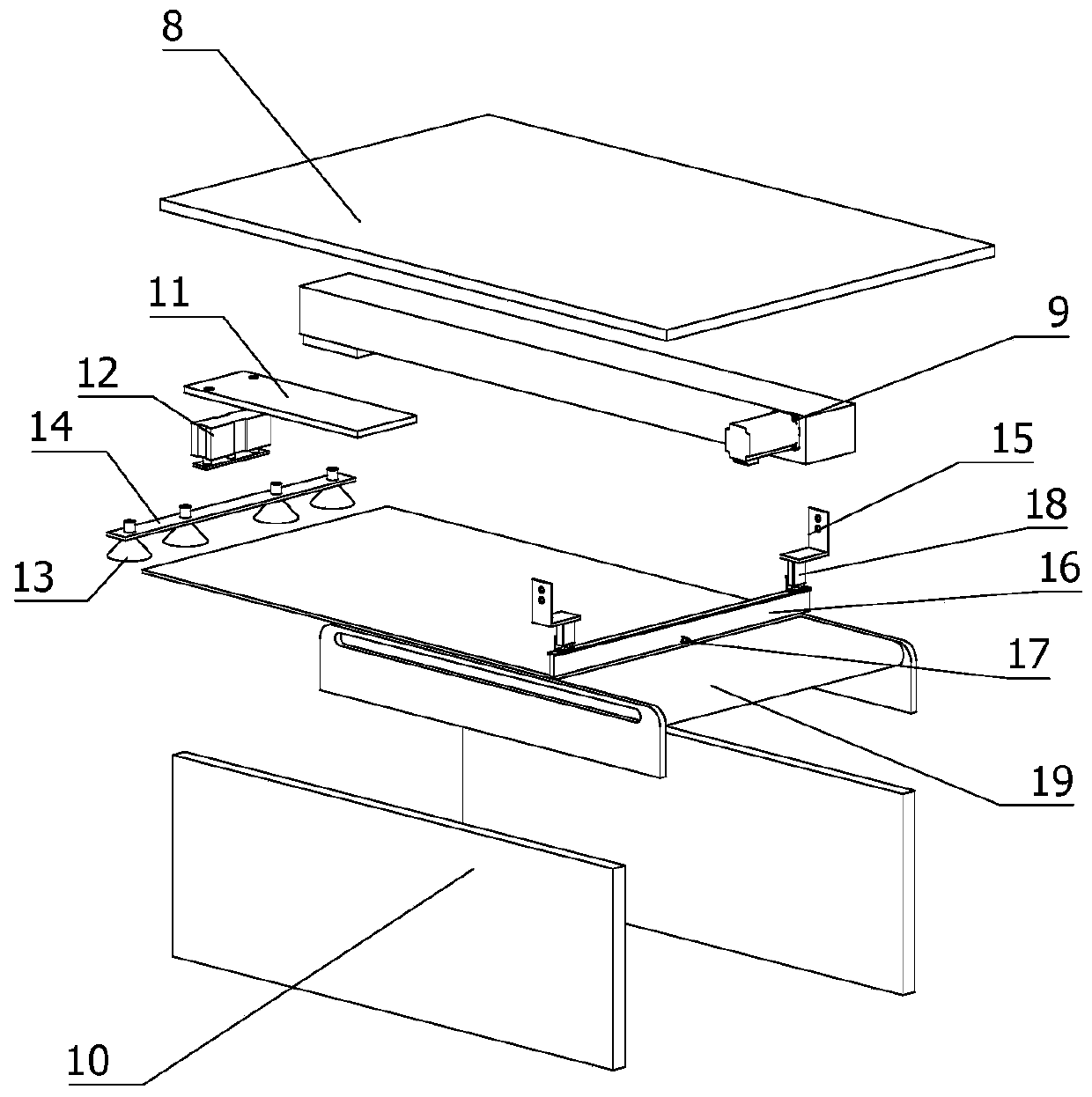

[0035] The specific shape of the electrode net set in the medical plasma sterilizer is as follows: Figure 15 As shown, the electrode net 71 is a hollow quadrilateral structure with open ends, and is formed by bending an aluminum alloy or stainless steel plate with a wall thickness of 0.5 to 2 mm. Shaped or oval through holes to facilitate discharge.

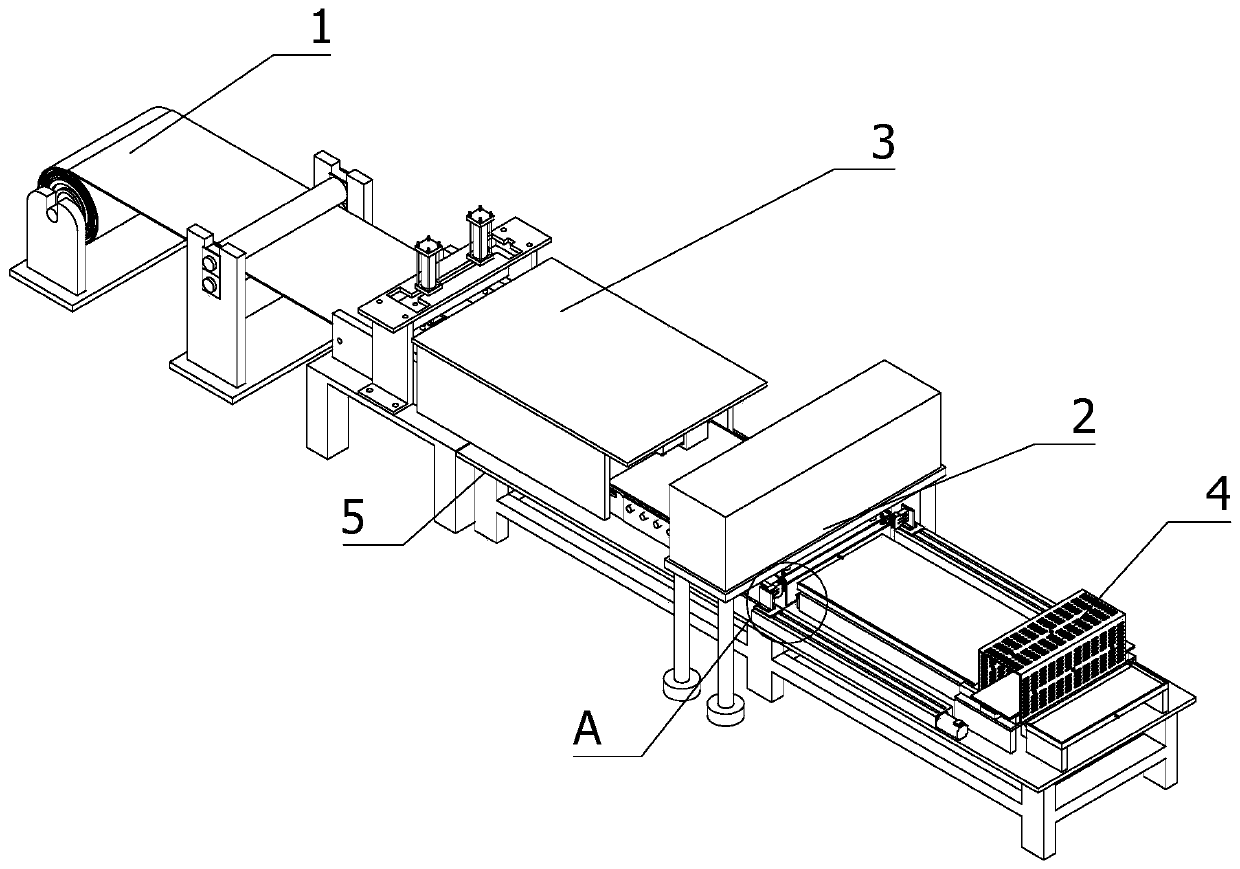

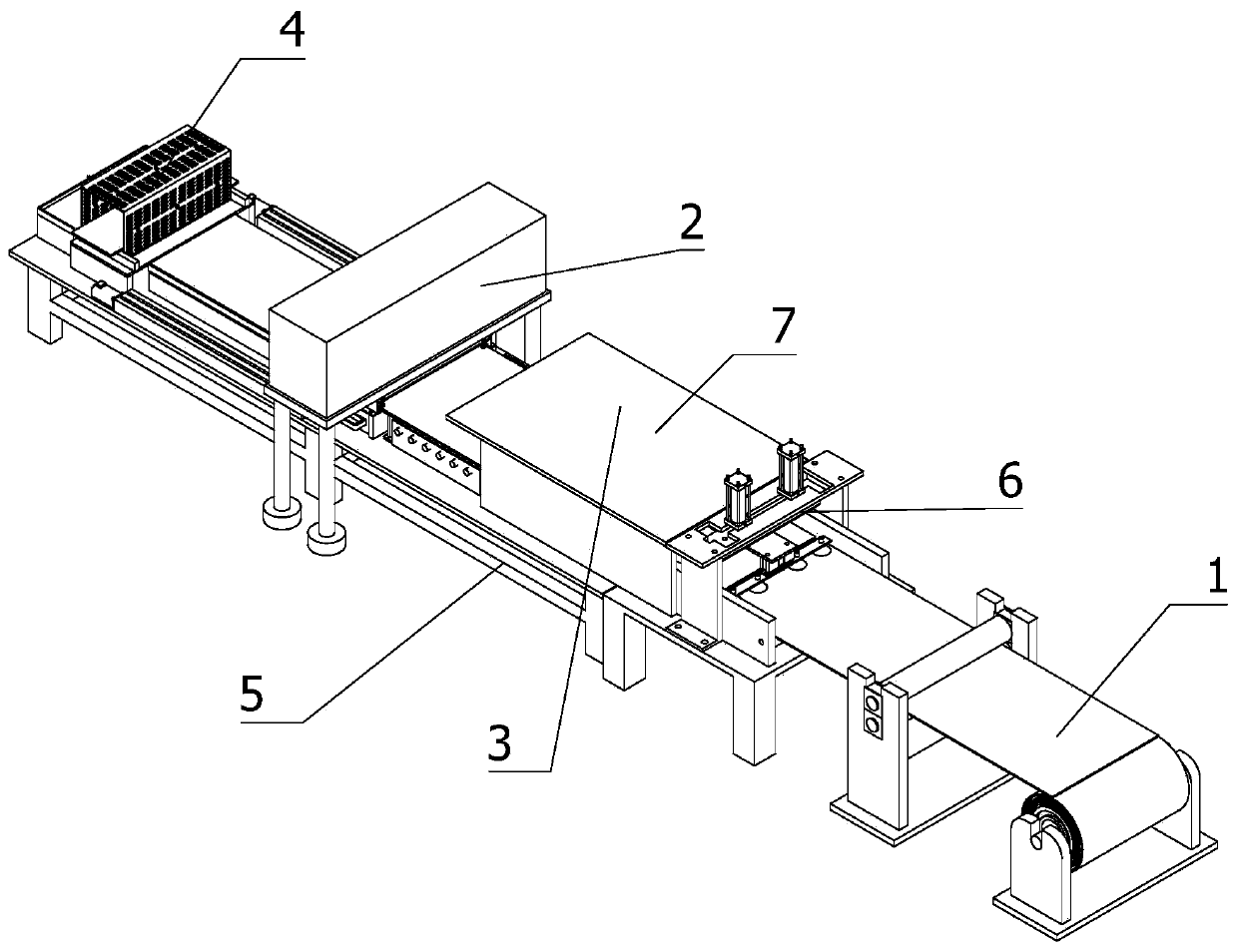

[0036] refer to Figure 1 to Figure 14 A medical plasma sterilizer shown in the automatic processing equipment with an electrode net, including a feeding mechanism 1, a pressing mechanism 2, a quantitative cutting mechanism 3, a bending mechanism 4 and a support frame 5, the feeding mechanism 1 is located at On the side of the support frame 5, the quantitative cutting mechanism 3, the pressing mechanism 2 and the bending mechanism 4 are all fixedly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com