A Stray Corrosion Ice Suppression Method in Electrochemical Machining

A technology of electrochemical machining and stray corrosion, applied in the supply of machining working medium, etc., can solve the problems of unknown protection effect, loss of electrode penetration conductive tape, difficult removal of acrylic glue, etc., to improve orifice quality and accuracy, The effect of saving post-processing time and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

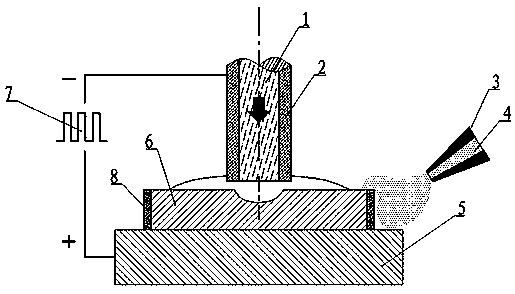

[0031] (1) Apply a small amount of deionized water evenly to the lower edge of the annular mold 8 and attach it to the surface to be processed of the workpiece 5;

[0032] (2) Low-temperature implementation measures are adopted. The nozzle 3 continuously sprays the cooling substance 4 to cool down the area of the workpiece to be processed, so that the deionized water between the lower edge of the ring mold 8 and the surface of the workpiece 5 is solidified and frozen, thereby making the ring mold 8. The lower edge is in close contact with the surface of the workpiece 5;

[0033] (3) In a low temperature environment, slowly pour an appropriate amount of deionized water into the container formed by the annular mold 8 and the surface of the workpiece 5, the deionized water in the container is frozen, and naturally freezes with the surface of the workpiece 5 to be processed and It has connection strength and forms an ice insulating protective film 6 with a certain thickness;

...

Embodiment 2

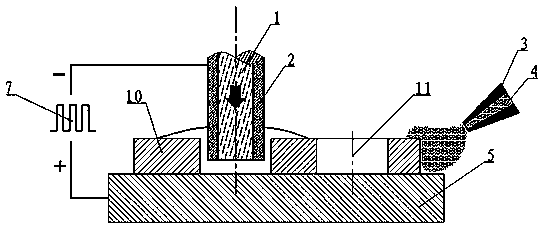

[0040] (1) Use the preformed ice layer 10 with the processing channel 11 to directly connect the prefabricated ice layer 10 to the surface of the workpiece 5 by freezing in a low temperature environment;

[0041] (2) Connect the workpiece 5 to the positive pole of the pulse power supply 7, and connect the tool electrode 2 to the negative pole of the pulse power supply 7. The working fluid 1 is supplied by flushing the inside of the tube electrode, and the tool electrode 2 moves under the drive of the feed mechanism. , the temperature controller controls the temperature of the working fluid 1, the heat and pressure of the flushing fluid in the tool electrode partially melt the ice layer to form a processing channel, and then perform electrochemical processing, the product 9 in the processing process is discharged smoothly, and the workpiece 5 The machined surface is better protected due to the existence of ice insulation 6;

[0042] (3) After the processing is finished, the tem...

Embodiment 3

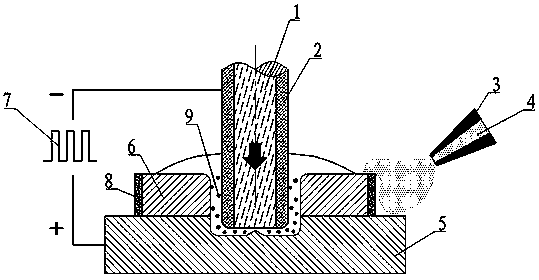

[0045] (1) Apply a small amount of working fluid evenly on the lower edge of the ring mold 8 and then attach it to the surface to be processed of the workpiece 5;

[0046] (2) Low-temperature implementation measures are adopted. The nozzle 3 continuously sprays the cooling substance 4 to cool down the area of the workpiece to be processed, so that the working fluid between the lower edge of the annular mold 8 and the surface of the workpiece 5 is solidified and frozen, so that the annular mold 8 The lower edge is in close contact with the surface of the workpiece 5;

[0047] (3) In a low temperature environment, slowly pour an appropriate amount of working fluid into the container formed by the annular mold 8 and the surface of the workpiece 5, the working fluid in the container is frozen, and naturally freezes with the surface of the workpiece 5 to be processed and has a connection Strength, forming an ice insulating protective film 6 with a certain thickness;

[0048] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com