Unidirectional moisture-wicking fabric and its preparation method and application

A moisture-conducting fabric and one-way moisture-guiding technology, applied in the field of dyeing and finishing, can solve the problems of slow one-way moisture-guiding speed, poor mechanical properties, and poor controllability, and achieve strong one-way moisture-guiding ability, improve mechanical properties, and improve operation. Controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In another aspect of the present invention, the present invention provides a method for preparing the aforementioned unidirectional moisture-wicking fabric. The preparation method includes: forming a hydrophobic layer on a first surface of a textile substrate by first electrospinning. Therefore, the operation is simple, convenient and easy to realize.

[0047] It should be noted that the hydrophobic layer and the textile matrix are consistent with the previous description, and will not be repeated here.

[0048] In some embodiments of the present invention, the preparation method further includes: forming a hydrophilic layer on the second surface of the textile substrate by second electrospinning.

[0049] It should be noted that the hydrophilic layer is consistent with the previous description, and will not be repeated here. The above-mentioned first surface and second surface refer to the two opposite surfaces of the textile matrix, and specifically refer to the hydr...

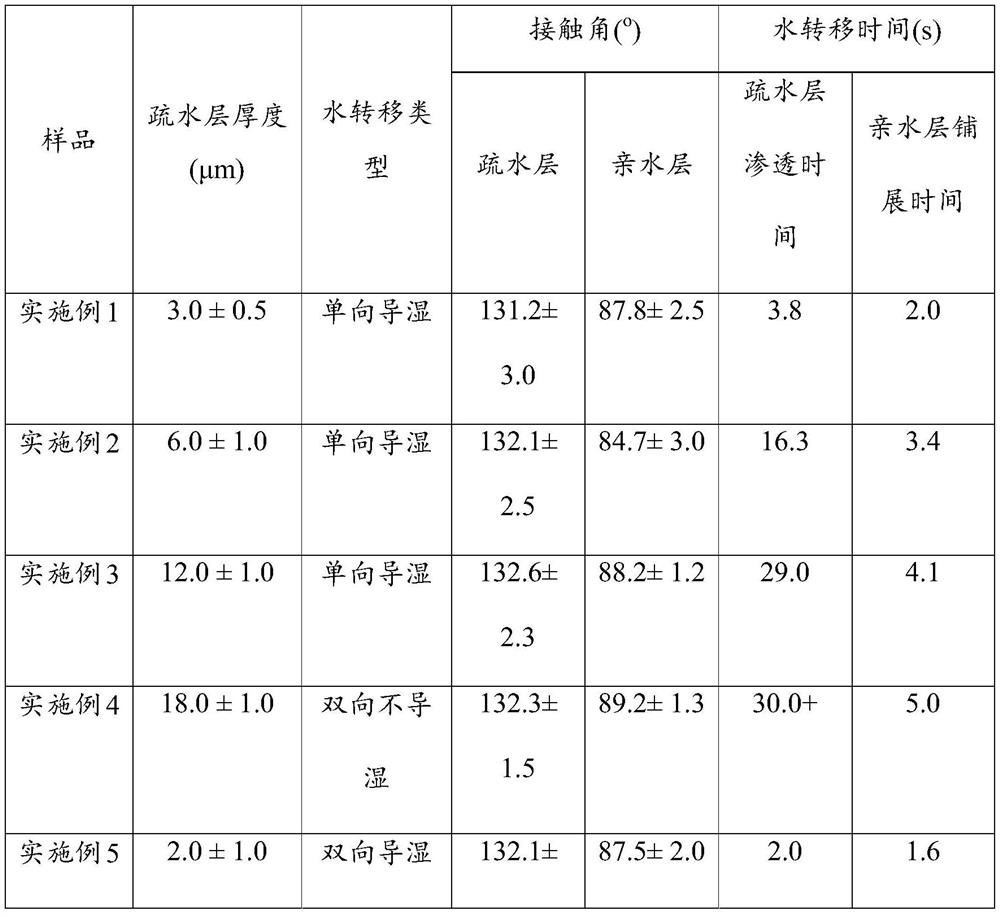

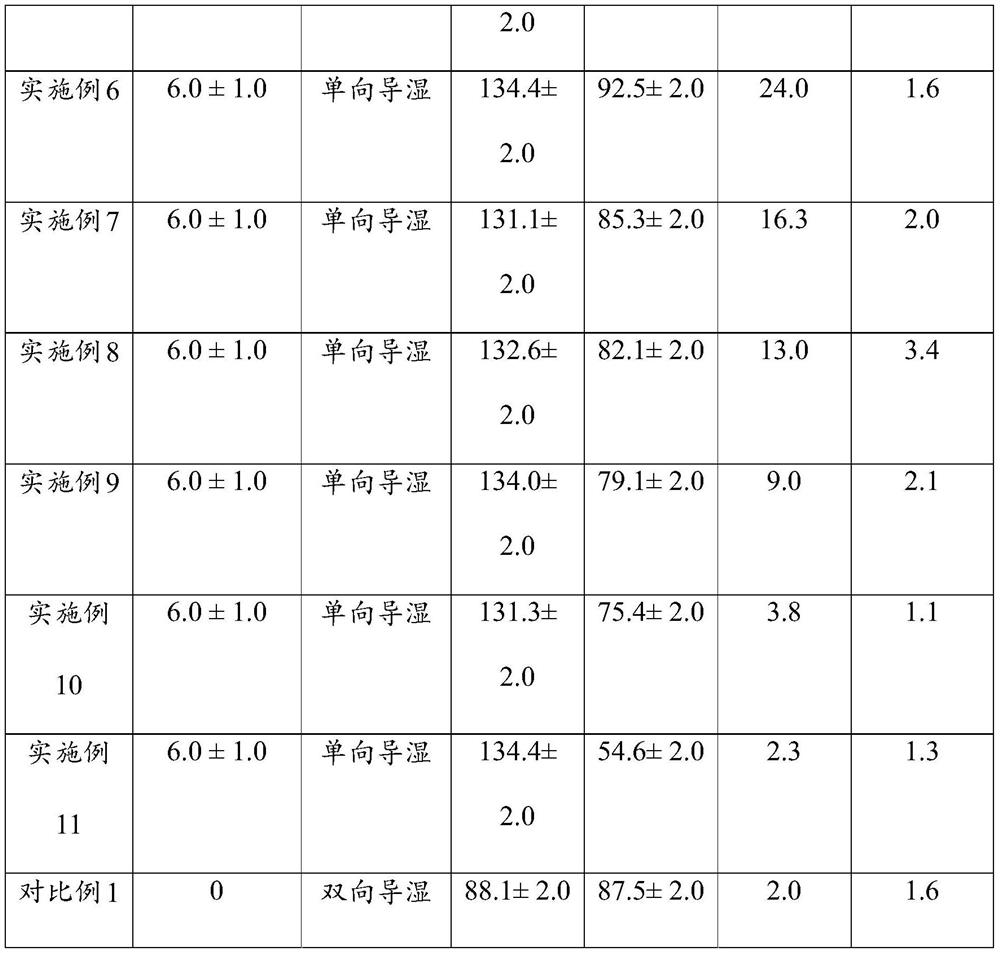

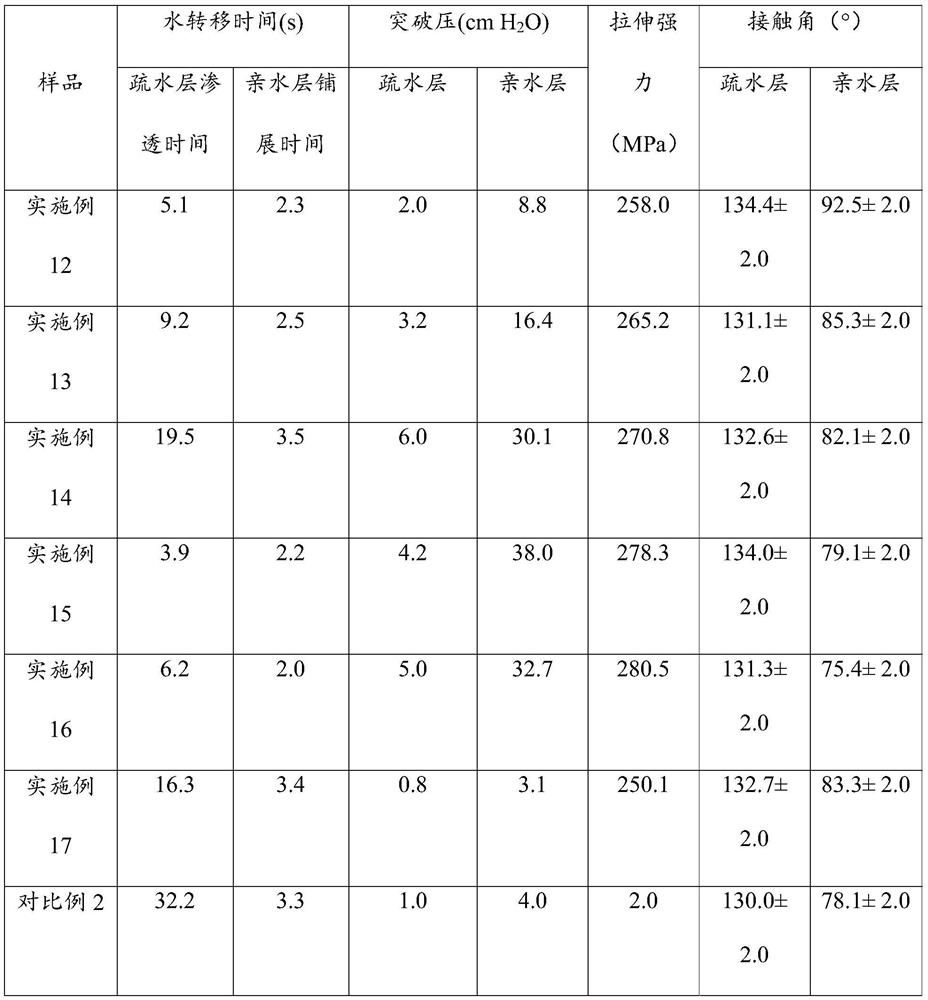

Embodiment 1

[0065] The preparation method of unidirectional moisture-wicking fabric comprises the following steps:

[0066] (1) Polyester fabric imitation silk treatment

[0067] Immerse the polyester fabric in an alkaline solution with a bath ratio of 1:30, treat it at 95°C for 60 minutes, wash and dry it to obtain a simulated silk polyester fabric; the alkaline solution includes sodium hydroxide with a mass concentration of 4g / L, and the mass concentration is 4g / L. Concentration is the lauryl dimethyl benzyl ammonium bromide of 2g / L;

[0068] (2) Preparation of hydrophobic spinning solution

[0069] Polystyrene (PS) was dissolved in tetrahydrofuran (THF) / dimethylformamide (DMF) mixed solvent to prepare hydrophobic spinning solution. Wherein, PS mass concentration is 9.8wt%, SDS mass concentration is 0.2wt%, THF mass concentration is 45wt%, DMF mass concentration is 45wt%;

[0070] (3) Electrospinning

[0071] Deposition of hydrophobic spinning solution on one side of simulated silk ...

Embodiment 2

[0073] The preparation method of the unidirectional moisture-conducting fabric in this example is the same as in Example 1, except that the electrospinning time is 10 minutes, and the thickness of the hydrophobic layer is 6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com