Novel cement-based particle blend non-combustible light composite heat preservation board and processing method thereof

A composite thermal insulation and cement-based technology, which is applied to other household appliances, applications, household appliances, etc., can solve the problems of increased thickness of thermal insulation materials, increase the pressure area, improve mechanical stability and strength, and reduce surface dusting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

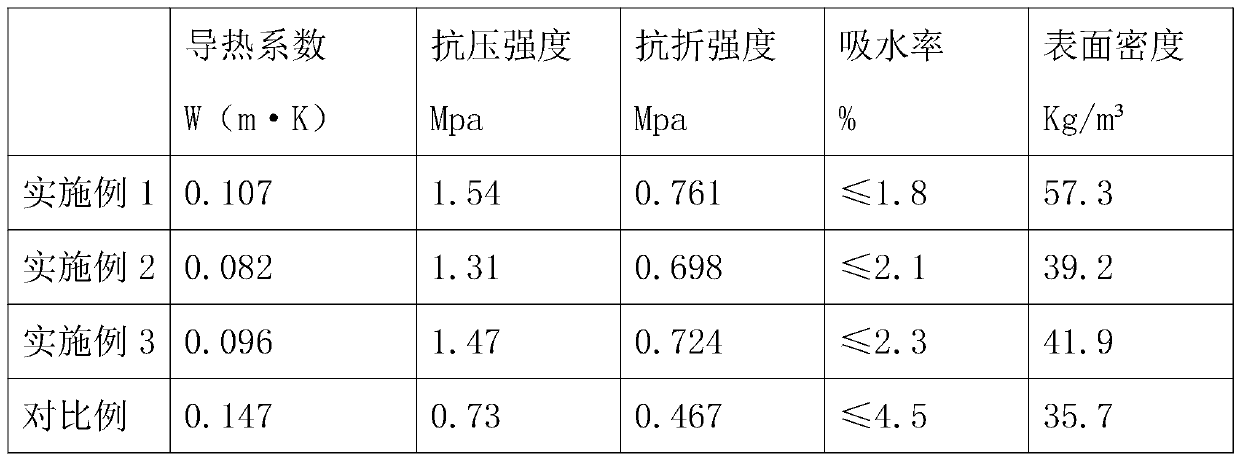

Examples

Embodiment 1

[0026] A new type of cement-based particle blended non-combustible lightweight composite insulation board, comprising the following components and their parts by weight: 80-100 parts of Portland cement, 30-50 parts of modified montmorillonite, 10-15 parts of fly ash, 1-5 parts of composite foaming agent, 1-5 parts of polycarboxylate superplasticizer, 3-5 parts of polypropylene fiber, 0.5-1.5 parts of styrene-acrylic emulsion, 1.5-5 parts of silicone water repellent, 4 parts of coagulation accelerator -8 parts, 0.5-1.5 parts of sodium metaaluminate, 0.5-1.5 parts of early strength agent, 1-3 parts of nano-boron fiber, 1-3 parts of nickel nanowire and 1-3 parts of water-repellent agent.

[0027] Specifically in this implementation, it is specifically: 80 parts of Portland cement, 30 parts of modified montmorillonite, 10 parts of fly ash, 1 part of composite foaming agent, 1 part of polycarboxylate water reducer, polypropylene fiber 3 parts, 0.5 parts of styrene-acrylic emulsion,...

Embodiment 2

[0039] A new type of cement-based particle blended non-combustible lightweight composite insulation board, comprising the following components and their parts by weight: 80-100 parts of Portland cement, 30-50 parts of modified montmorillonite, 10-15 parts of fly ash, 1-5 parts of composite foaming agent, 1-5 parts of polycarboxylate superplasticizer, 3-5 parts of polypropylene fiber, 0.5-1.5 parts of styrene-acrylic emulsion, 1.5-5 parts of silicone water repellent, 4 parts of coagulation accelerator -8 parts, 0.5-1.5 parts of sodium metaaluminate, 0.5-1.5 parts of early strength agent, 1-3 parts of nano-boron fiber, 1-3 parts of nickel nanowire and 1-3 parts of water-repellent agent.

[0040] Specifically in this implementation, it is specifically: 100 parts of Portland cement, 50 parts of modified montmorillonite, 15 parts of fly ash, 5 parts of composite foaming agent, 5 parts of polycarboxylate water reducer, polypropylene fiber 5 parts, 1.5 parts of styrene-acrylic emulsi...

Embodiment 3

[0052] A new type of cement-based particle blended non-combustible lightweight composite insulation board, comprising the following components and their parts by weight: 80-100 parts of Portland cement, 30-50 parts of modified montmorillonite, 10-15 parts of fly ash, 1-5 parts of composite foaming agent, 1-5 parts of polycarboxylate superplasticizer, 3-5 parts of polypropylene fiber, 0.5-1.5 parts of styrene-acrylic emulsion, 1.5-5 parts of silicone water repellent, 4 parts of coagulation accelerator -8 parts, 0.5-1.5 parts of sodium metaaluminate, 0.5-1.5 parts of early strength agent, 1-3 parts of nano-boron fiber, 1-3 parts of nickel nanowire and 1-3 parts of water-repellent agent.

[0053] Specifically in this implementation, it is specifically: 90 parts of Portland cement, 40 parts of modified montmorillonite, 13 parts of fly ash, 3 parts of composite foaming agent, 3 parts of polycarboxylate water reducer, polypropylene fiber 4 parts, 1 part of styrene-acrylic emulsion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com