Method for preparing cellulose grafted copolymer in homogeneous phase by utilizing enzymatic system

A cellulose grafting and copolymer technology, applied in the field of functional cellulose and its preparation, can solve complex conditions, toxic and harmful chemicals and other problems, achieve wide application prospects, improve thermal stability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

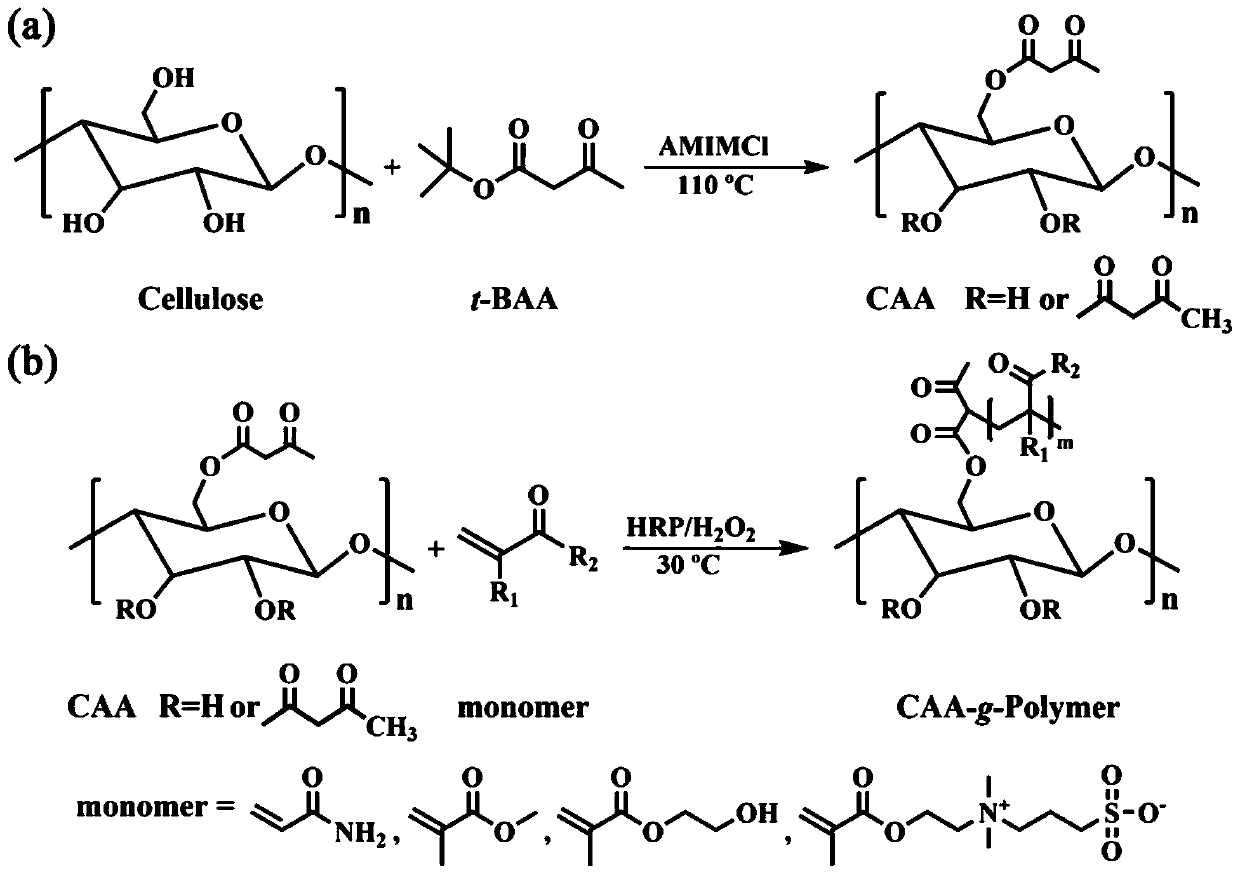

[0041] (1) Cut 2g of wood pulp board cellulose (purchased from Henan Xinxiang Natural Chemical Co., Ltd., DP=900), add 44g of ionic liquid 1-allyl-3-methylimidazolium chloride (AMIMCl), and heat to 90 °C, stirred to obtain a homogeneous solution. Add 41g of N,N-dimethylformamide and continue stirring to obtain a clear and transparent solution.

[0042] (2) Weigh 30 g of the cellulose solution and heat it to 110° C. in an oil bath. Then weigh 2.7g of tert-butyl acetoacetate, add it into the above liquid, continue heating and stirring for 1.5h, test its water solubility, and stop the reaction after the water solubility is good. Pour the reaction solution into a large amount of ethanol to precipitate a precipitate, filter and dry with suction to obtain cellulose acetoacetate.

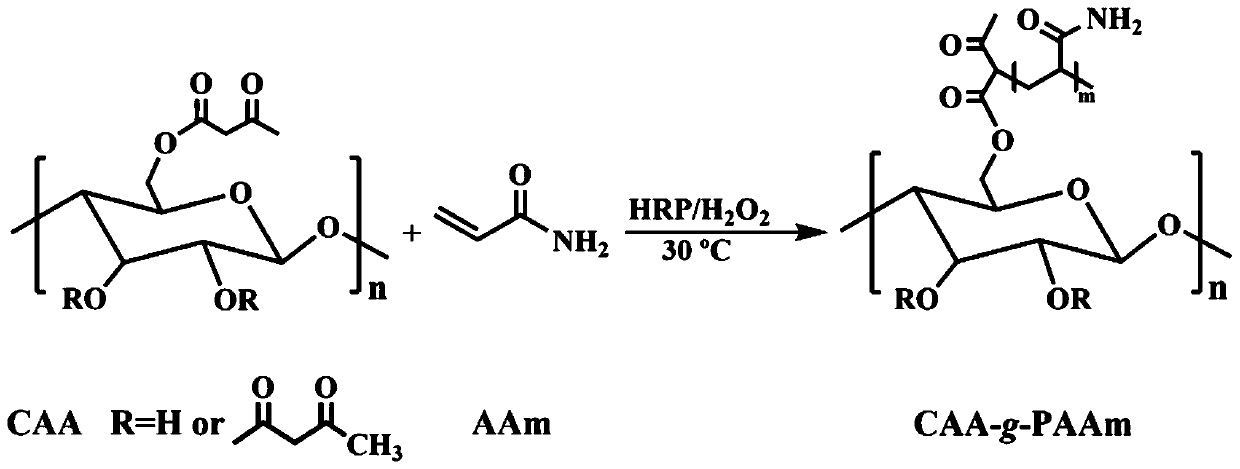

[0043] (3) The cellulose acetoacetate was prepared into an aqueous solution with a mass fraction of 1% by using a PBS buffer solution with a pH of 7.2. Weigh 11.5 g of cellulose acetoacetate aqueous sol...

Embodiment 2

[0051] (1) Cut 2g of wood pulp board cellulose (purchased from Henan Xinxiang Natural Chemical Co., Ltd., DP=900), add 44g of ionic liquid 1-allyl-3-methylimidazolium chloride (AMIMCl), and heat to 90 °C, stirred to obtain a homogeneous solution. Add 41g of N,N-dimethylformamide and continue stirring to obtain a clear and transparent solution.

[0052] (2) Weigh 30 g of the cellulose solution and heat it to 110° C. in an oil bath. Then weigh 2.7g of tert-butyl acetoacetate, add it into the above liquid, continue heating and stirring for 1.5h, test its water solubility, and stop the reaction after the water solubility is good. Pour the reaction solution into a large amount of ethanol to precipitate a precipitate, filter and dry with suction to obtain cellulose acetoacetate.

[0053] (3) The cellulose acetoacetate was prepared into an aqueous solution with a mass fraction of 1% by using a PBS buffer solution with a pH of 7.2. Weigh 11.5 g of cellulose acetoacetate aqueous sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com