Internal combustion engine and design and manufacturing method thereof

A manufacturing method and technology for an internal combustion engine, which can be applied to internal combustion piston engines, mechanical equipment, combustion engines, etc., can solve problems such as reducing harmful emissions and low thermal efficiency of internal combustion engines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

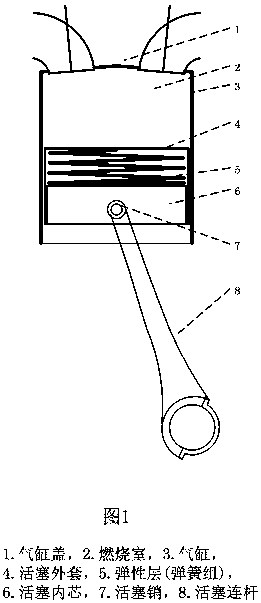

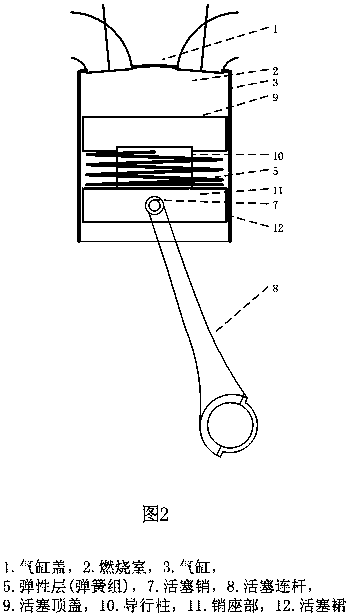

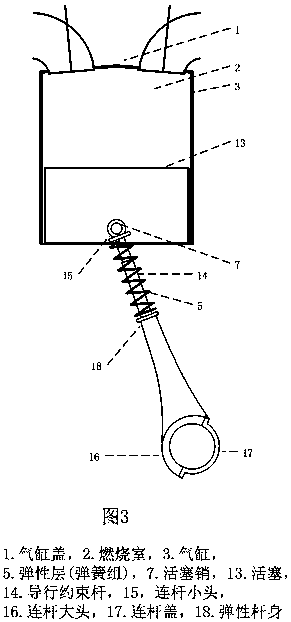

[0080] High compression ratio fuel integrated engine

[0081]The implementation example of the scheme of the present invention is a high compression ratio fuel oil integrated engine, that is, a reciprocating piston engine with a compression ratio of more than 30 and various fuels can be used respectively. The specific design and manufacturing method of this example is that on the basis of the existing supercharged diesel engine, the piston, the piston connecting rod and the fuel injection etc. are designed and modified accordingly, so that the piston becomes an elastic variable length piston, and the piston connecting rod becomes an elastic variable length piston. The variable-length piston connecting rod, the combustion chamber possesses elasticity and becomes an elastic energy storage structure, so that the engine can achieve various functions of the scheme of the present invention. The engine adopts aluminum alloy or cast iron body, which can withstand the pressure of more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com