Particle size grading method of micro-nano-scale emulsion droplets and solid particles

A solid particle, micro-nano-scale technology, applied in the field of chemistry, can solve problems such as uncontrollable drug release speed, uneven micro-nano spheres, large particle size side effects, etc., to overcome poor separation effect, maintain nutritional components, and improve release drug speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

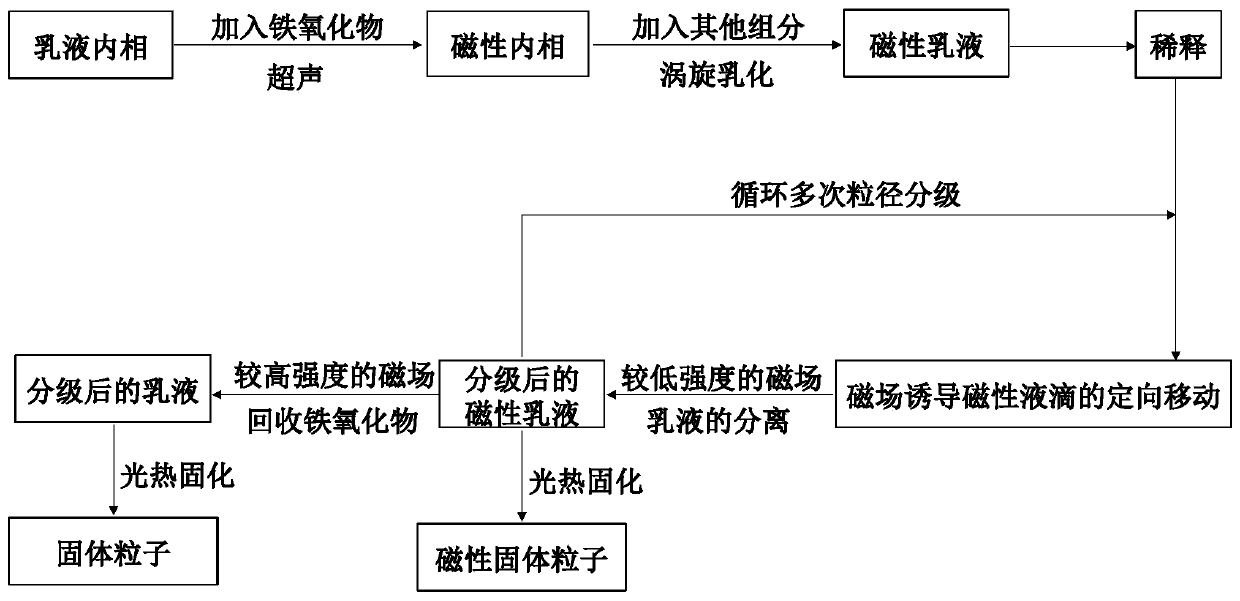

Method used

Image

Examples

Embodiment 1

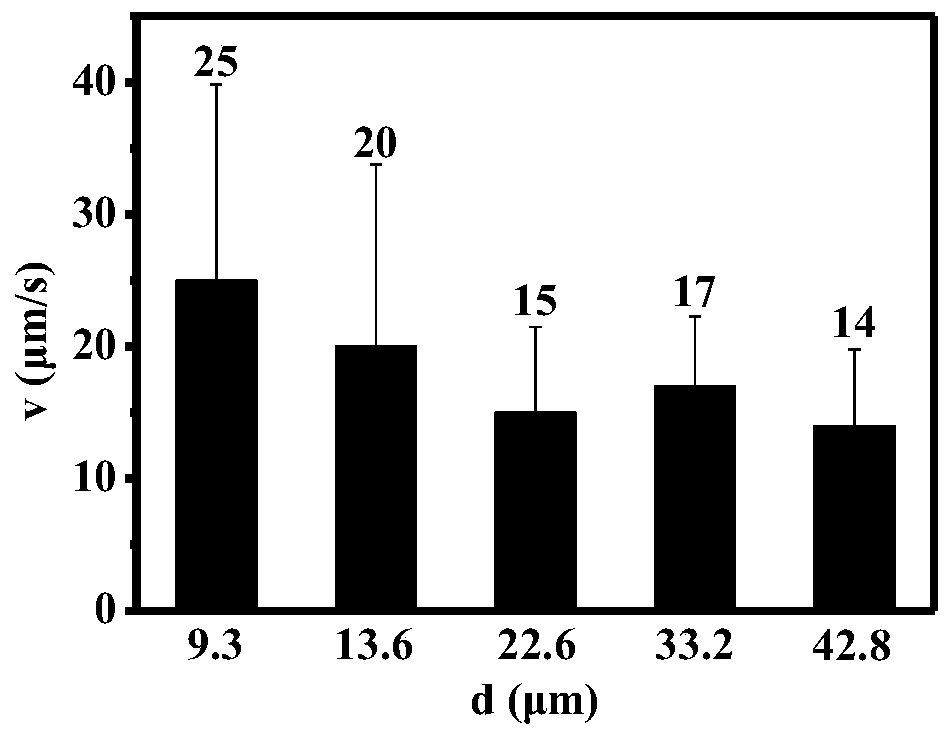

[0035] 25mg of Fe 2 o 3 Add to 5mL of ethoxylated trimethylolpropane triacrylate, sonicate for 25min to make Fe 2 o 3 Disperse evenly. Weigh 0.33 g of ethoxylated trimethylolpropane triacrylate, 0.33 g of 2-(perfluorooctyl) ethyl methacrylate, 0.33 g of 0.4% F127 in 5 centrifuge tubes (aq) Mixing, on the basis of vortex oscillation for 3 minutes, use a homogenizer to shear the magnetic emulsion at a rate of 3500rpm, 5000rpm, 7000rpm, 11000rpm, and 20000rpm respectively, that is, prepare magnetic emulsions with different emulsification properties, and measure them with a micron particle size analyzer. The particle size of an emulsion; take 20μL emulsion and 1.6mL0.4%F127 (aq) Mix, shake up and down gently 20 times to dilute the emulsion, take the diluted emulsion and take a translational video under the microscope. Through statistical calculation, the quantitative relationship between the particle size and the translation velocity of the magnetic droplet is obtained.

[0...

Embodiment 2

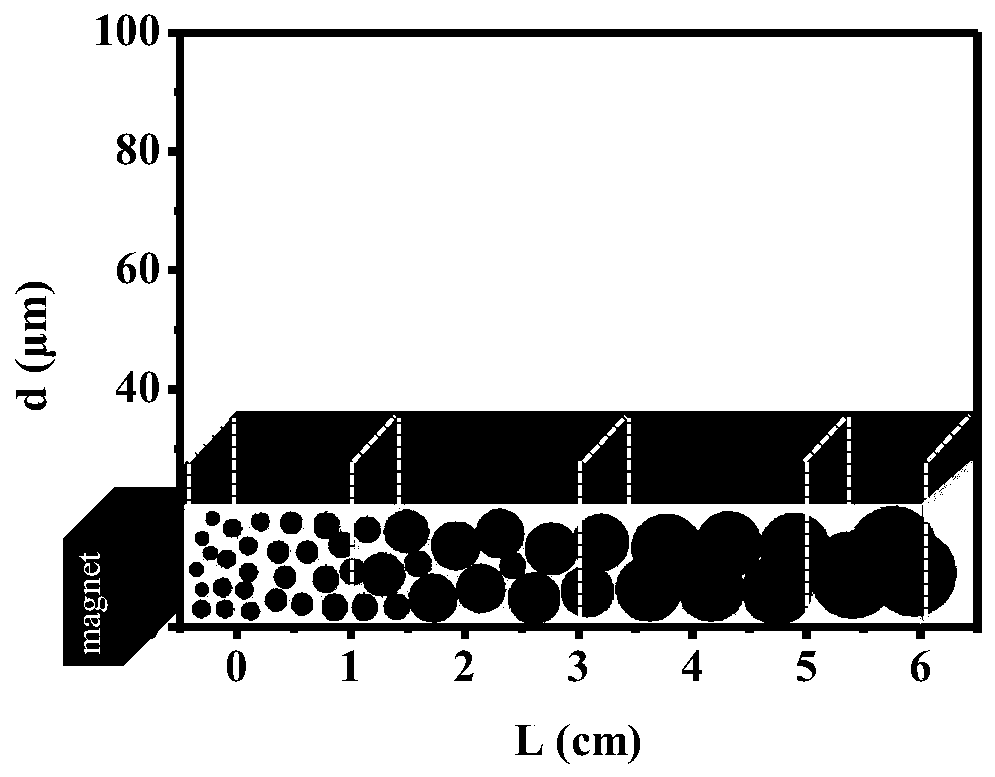

[0039] Prepare 2g of magnetic emulsion, add 16g of ultra-pure water to dilute, invert the centrifuge tube up and down to mix evenly, pour it into the container, use a magnet to attract different times on the side close to the container, and take samples at a distance of 0cm from the magnet to measure the particle size. path.

[0040] verify: image 3 is a schematic diagram of particle size classification. From Figure 4 It can be seen that with the increase of time, the number of small-diameter magnetic liquid droplets at 0 cm increases gradually relative to the large-diameter magnetic liquid droplets.

Embodiment 3

[0043] Prepare 2g of magnetic emulsion, add 16g of ultrapure water to dilute, invert the centrifuge tube up and down to mix evenly, pour it into the container, use a magnet to attract different time on the side close to the container, and take samples at a distance of 6cm from the magnet to measure the particle size. path.

[0044] Authentication: from Figure 5 It can be seen that with the increase of time, the small-diameter magnetic liquid droplets at 6 cm gradually decrease compared with the large-diameter magnetic liquid droplets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com