Waste liquid collection device for gel permeation chromatography

A gel permeation chromatography and waste liquid collection technology, applied in the field of waste liquid collection, can solve the problems of long pretreatment process, dripping on the ground, and ground corrosion, so as to shorten the time for replacing waste liquid barrels, avoid dripping, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

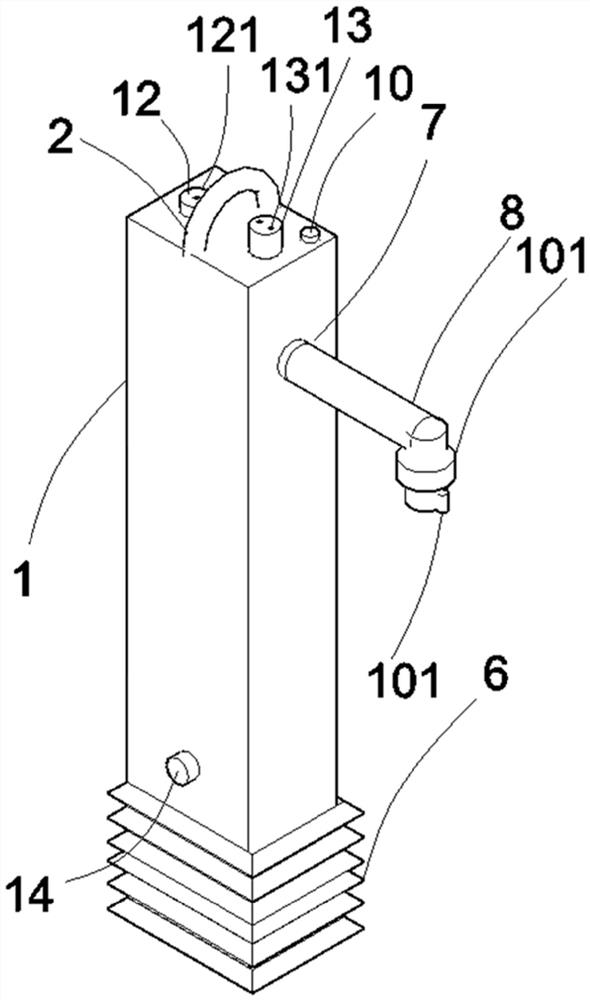

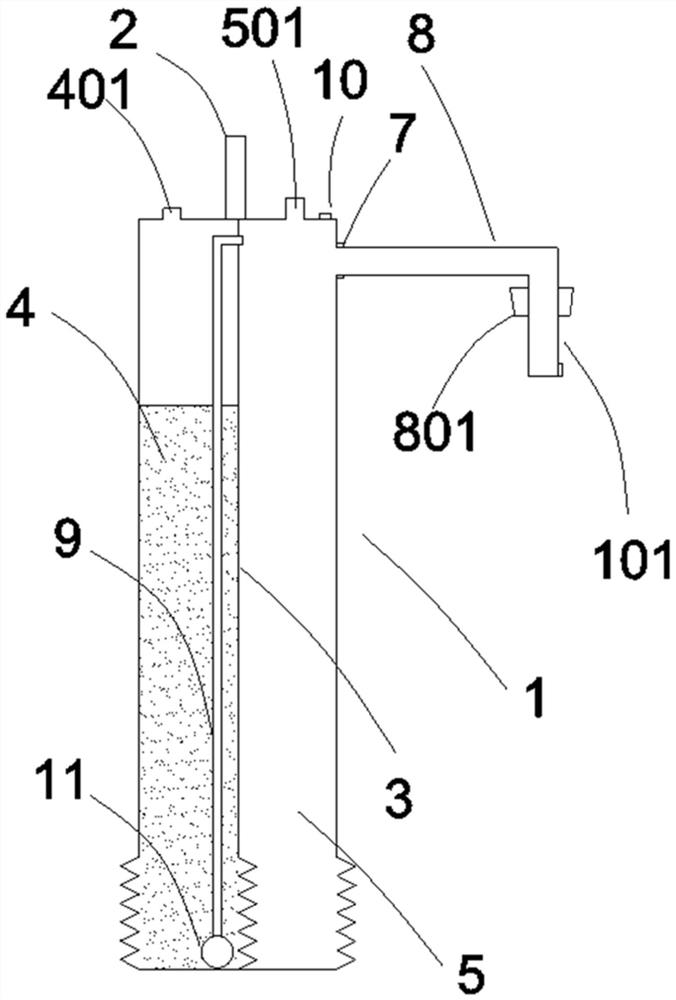

[0037] like Figure 1-2 As shown, a waste liquid collection device for a gel permeation chromatograph, comprising: a waste liquid transfer tank 1 and a waste liquid barrel (for a common 25L volume waste liquid barrel, not shown in the figure); the waste liquid transfer tank is a cuboid with an inner cavity;

[0038] The waste liquid transfer tank stands outside the waste liquid barrel; the height of the waste liquid transfer tank is greater than the height of the waste liquid barrel;

[0039] A handle 2 is provided on the top of the waste liquid transfer tank, and a diaphragm 3 is provided in the middle of the inner cavity of the waste liquid transfer tank, and the inner cavity is divided into an absorbent chamber 4 and a waste liquid transfer chamber 5;

[0040] The top of the waste liquid transfer tank is provided with an absorbent liquid inlet 401 and a liquid discharge pipe inlet 501, and the absorbent liquid inlet and the liquid discharge pipe inlet are respectively conn...

Embodiment 2

[0056] As another implementation of Example 1, the waste liquid barrel can be processed to have a depression in the middle that is compatible with the waste liquid transfer tank, and the waste liquid transfer tank can be placed in the depression; this arrangement occupies less space , but because the waste liquid tank needs to be customized, it will undoubtedly increase the cost, so it is not the first choice.

Embodiment 3

[0058] Installation method: When replacing the waste liquid barrel, pull out the sealing plug from the old waste liquid barrel, lift the waste liquid transfer tank, put the extension tube into the mouth of the new waste liquid barrel, plug the sealing plug tightly, and make the waste liquid transfer tank stand again Just next to the new waste container. It should be noted that before putting the extension tube into the mouth of the new waste liquid barrel, the waste liquid transfer tank should be kept lifted to avoid leakage of waste liquid in the waste liquid transfer tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com