Design method of toe-in control arm

A design method and control arm technology, applied in calculation, instrumentation, electrical digital data processing, etc., can solve problems such as single method, insufficient structure, waste of time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

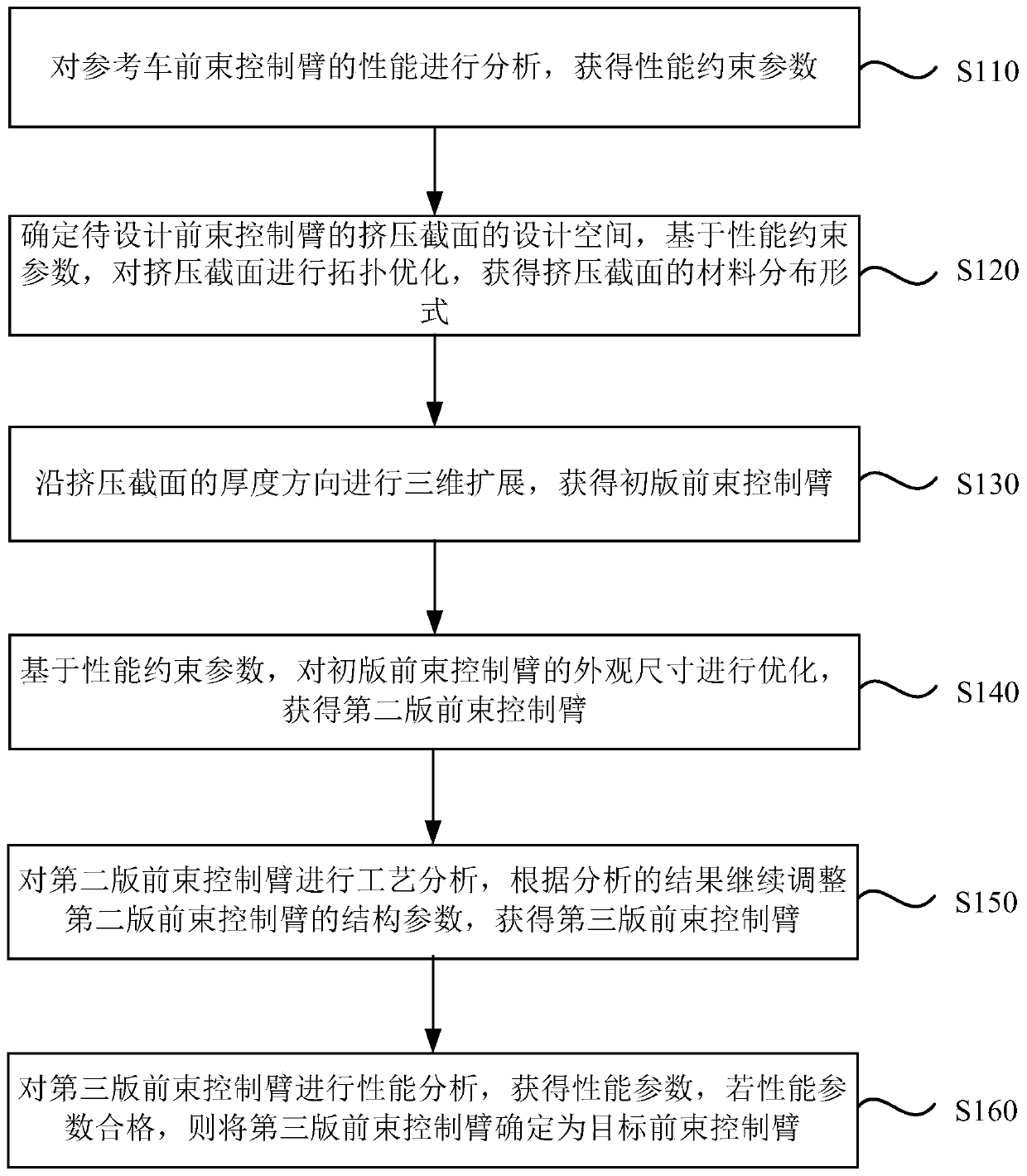

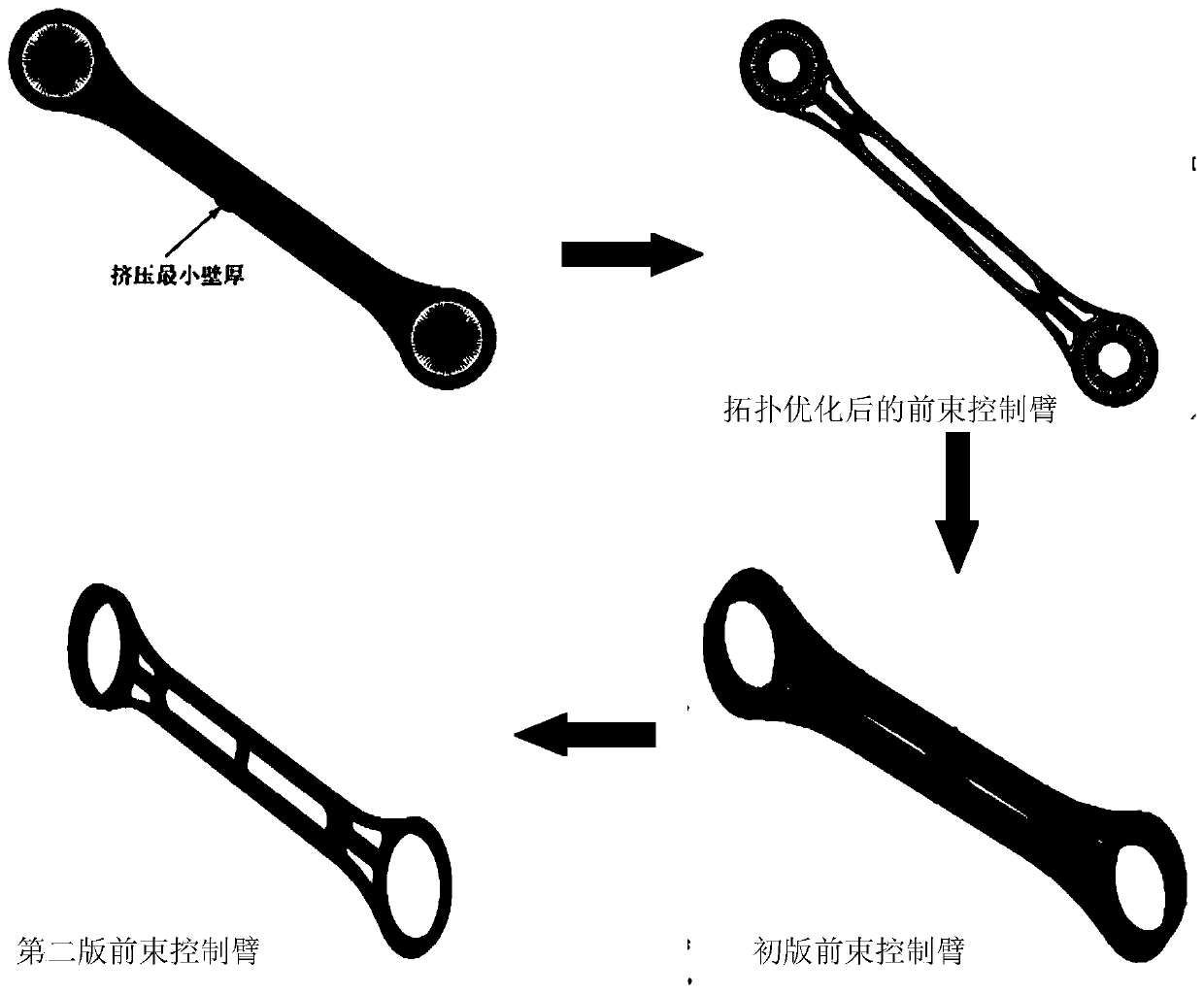

[0047] figure 1 It is a flow chart of a design method of a toe control arm provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of designing a toe control arm of a vehicle, such as figure 1 As shown, the method specifically includes the following steps:

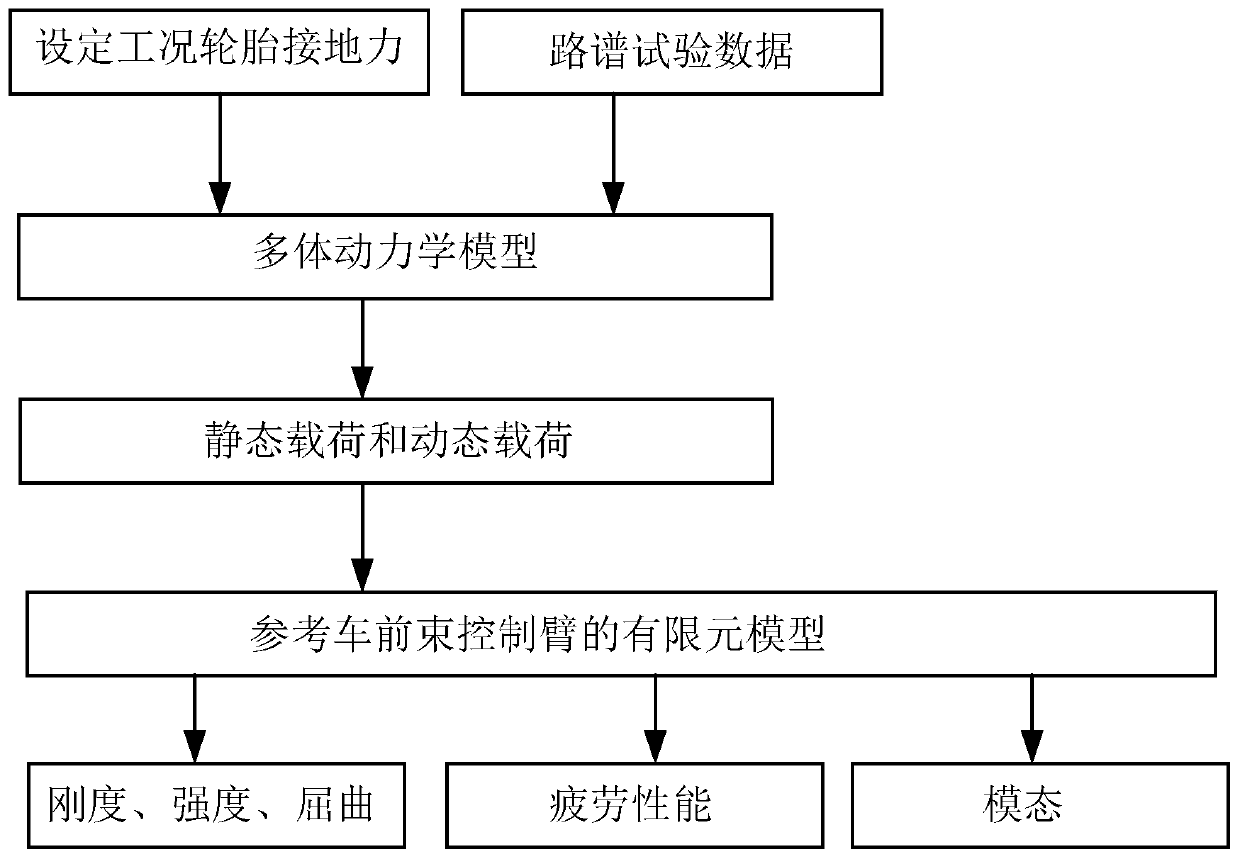

[0048] Step 110, analyzing the performance of the reference toe control arm to obtain performance constraint parameters.

[0049] Among them, the performance constraint parameters include: steady-state performance parameters, fatigue performance parameters and modal performance parameters. Steady-state performance parameters can include performance parameters such as stiffness and strength of the toe-in control arm; fatigue performance parameters can include fatigue life and fatigue damage values at various points of the toe-in control arm; modal performance parameters can include the toe-in control arm The mode shapes and natural frequencies of the first six elastic modes. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com