Composite microporous membrane containing nanofiber-shaped porous layer oriented in transverse stretching direction

A transverse stretching and nanofiber technology, applied in the field of microporous membranes, can solve the problems of increasing production costs, affecting ion transport performance, and reducing the yield of microporous membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] [Preparation of composite microporous membrane]

[0049] [the first method]

[0050] In a solution of the present invention, the composite microporous membrane can be prepared by the following method:

[0051] Coating a coating solution on one side or both sides of the longitudinally stretched film, and then stretching in the transverse direction, the composite microporous membrane is prepared. The composite microporous membrane includes at least one layer of polypropylene porous base layer and the At least one layer of non-polyolefin polymer porous layer in the form of nanofibers oriented along the transverse stretching direction of the composite microporous membrane on one or both sides of the polypropylene porous base layer.

[0052] In one solution of the present invention, the longitudinally stretched film is coated and then subjected to a transverse stretching process, wherein the longitudinally stretched film is subjected to transverse stretching to prepare the ...

Embodiment 1

[0145] The homopolypropylene resin whose melt index is 2.5g / 10min is mixed with the polypropylene beta crystal nucleating agent N,N-dicyclohexyl-2,6 naphthalene diamide accounting for 0.03wt% of the homopolypropylene resin, and mixed uniformly in After melting at a temperature of 200-250°C, a polypropylene layer melt is formed;

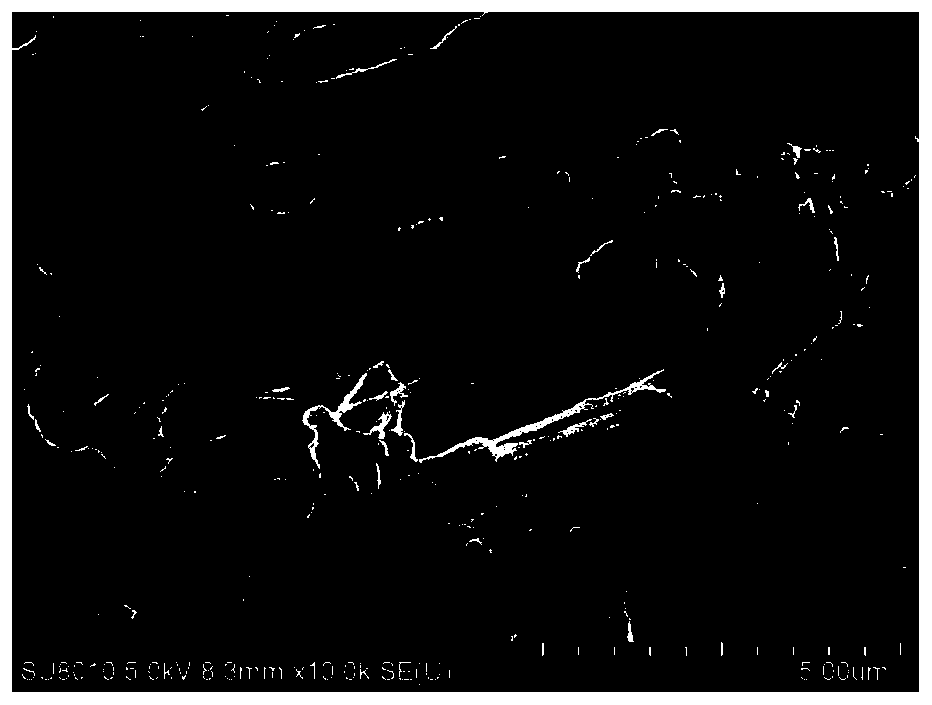

[0146] After the polypropylene layer melt is extruded through a T-die, it is cooled and crystallized on a casting roll at 128°C to obtain a polypropylene film containing β crystals, that is, a high β crystal film. After stretching the film 4.5 times longitudinally at 100°C, the two surfaces are respectively coated with an aqueous dispersion with a solid content of 20% and a polyvinylidene fluoride particle size of 200nm to form a coating with a thickness of 6 microns, and then enter In the transverse stretching system, 3.0 times transverse stretching is carried out at 135° C. to obtain a composite polypropylene microporous membrane with a thickness of...

Embodiment 2

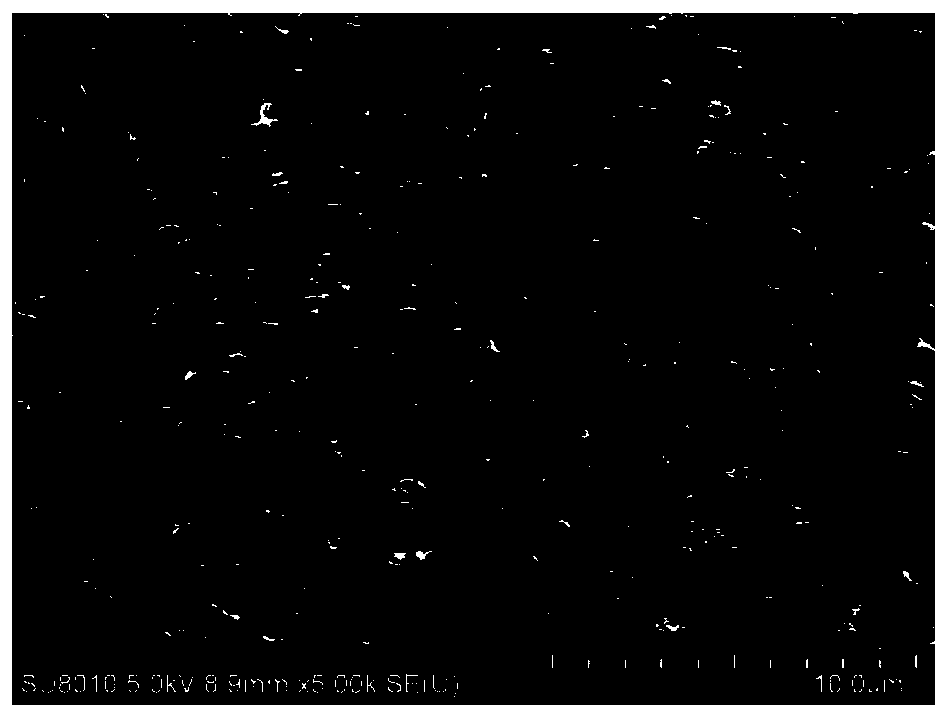

[0149] After the homopolypropylene resin with a melt index of 2.5g / 10min is melted at a temperature of 200-250°C by a single-screw extruder, it is extruded through a T-shaped die and wound at a speed of 50m / min to obtain a highly oriented Polypropylene diaphragm. After the polypropylene film is annealed and crystallized at 125°C, a polypropylene pre-stretched film is obtained. After the polypropylene pre-stretched film is pre-stretched by 40% at 30°C, it is further stretched by 50% at 125°C to obtain a longitudinally stretched film with a porosity of 30%. The two surfaces of the longitudinally stretched film are respectively coated with an aqueous dispersion with a solid content of 20% and a polyvinylidene fluoride particle size of 200nm to form a coating with a thickness of 6 microns, and then enter the transverse stretching system at 140°C. 4.0 times transverse stretching to obtain a composite polypropylene microporous membrane with a thickness of 20 microns. The thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com