Ozone catalyst as well as preparation method and application thereof

A catalyst, ozone technology, applied in molecular sieve catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of different proportions of transition metal catalysts, large differences in value, and different catalytic effects. , to achieve the effect of high cost performance, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the preparation method of the above ozone catalyst, the formula amount of metal ore and the stone material containing transition metal oxides are crushed, then mixed with the formula amount of spacers, and packed into plastic hollow balls to obtain the ozone catalyst.

[0039] The application of the above-mentioned ozone catalyst is to use the ozone catalyst for the treatment of waste water or waste gas under the irradiation of ultraviolet rays.

Embodiment 1

[0041] A kind of ozone catalyst, comprises the component of following weight part:

[0042] 1 part of bamboo charcoal, 2 parts of hematite and 3 parts of manganese placer; the particle size of bamboo charcoal is 10mm; the particle size of hematite is 20mm; the particle size of manganese placer is 30mm;

[0043] The preparation method of the above-mentioned ozone catalyst is as follows: pulverize the hematite and manganese placer of the formula quantity, then mix with the bamboo charcoal of the formula quantity, pack into the plastic hollow ball, and obtain the ozone catalyst.

[0044] The above ozone catalyst is used to catalyze ozone for the treatment of waste water and waste gas.

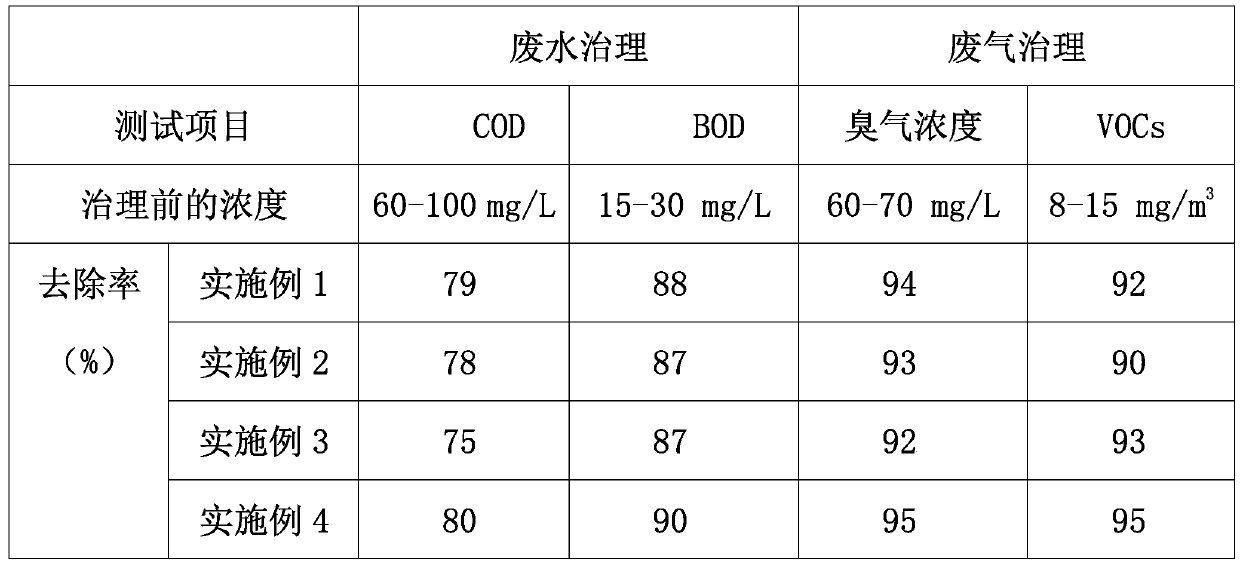

[0045] The results of wastewater and waste gas treatment are shown in Table 1.

Embodiment 2

[0047] A kind of ozone catalyst, comprises the component of following weight part:

[0048] 1 part of charcoal, 3 parts of manganese placer and 2 parts of volcanic rock; the particle size of charcoal is 20mm; the particle size of manganese placer is 20mm; the particle size of volcanic rock is 20mm;

[0049] The preparation method of the above-mentioned ozone catalyst is to crush the manganese placer and volcanic stone of the formula quantity, then mix with the charcoal of the formula quantity, and pack them into plastic hollow balls to obtain the ozone catalyst.

[0050] The above ozone catalyst is used to catalyze ozone for the treatment of waste water and waste gas.

[0051] The results of wastewater and waste gas treatment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com