Antibacterial ultraviolet fabric

An anti-ultraviolet and fabric technology, applied in the field of textile fabrics, can solve the problems of single anti-radiation or antibacterial function, loss of efficacy, etc., and achieve the effect of improving anti-radiation and anti-ultraviolet ability, improving adhesion, and excellent anti-radiation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

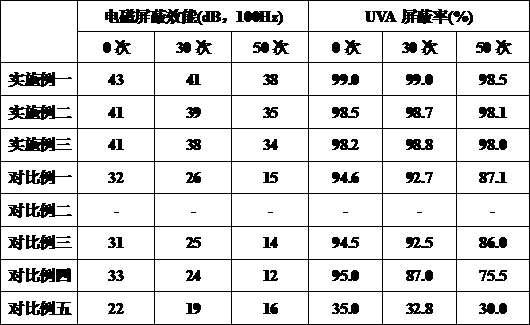

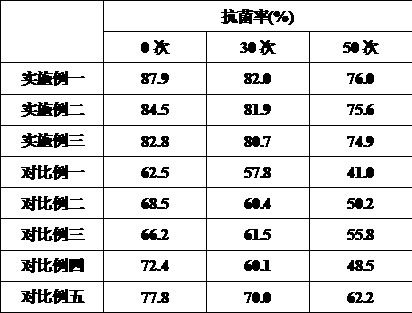

Examples

Embodiment 1

[0033] The antibacterial and anti-ultraviolet fabric of the present embodiment comprises a base cloth layer, a moisture-absorbing layer, a grid air-permeable layer and a surface layer; On, the sunscreen layer is set on the mesh air-permeable layer.

[0034] The base fabric layer is made by interweaving warps and wefts perpendicular to each other, the warps are antibacterial fibers, the wefts are composed of flax fibers and vinylon fibers in a weight ratio of 1:2.5, the diameter of the warps is 50 microns, the diameter of the wefts is 43 microns, and the warps The density is 78 threads / cm, and the weft thread density is 52 threads / cm;

[0035] The antibacterial fiber is modified cellulose acetate with antibacterial monomer grafted on the side chain of cellulose acetate; the surface layer is made of blended natural fiber and synthetic fiber impregnated with modified nanoemulsion.

[0036] The preparation method of the antibacterial fiber of the present embodiment may comprise t...

Embodiment 2

[0047] The antibacterial and anti-ultraviolet fabric of the present embodiment comprises a base cloth layer, a moisture-absorbing layer, a grid air-permeable layer and a surface layer; On, the sunscreen layer is set on the mesh air-permeable layer.

[0048] The base fabric layer is made by interweaving warps and wefts perpendicular to each other, the warps are antibacterial fibers, the wefts are composed of flax fibers and vinylon fibers in a weight ratio of 1:2, the diameter of the warps is 48 microns, the diameter of the wefts is 42 microns, and the warps The density is 77 threads / cm, and the weft thread density is 50 threads / cm;

[0049] The antibacterial fiber is modified cellulose acetate with antibacterial monomer grafted on the side chain of cellulose acetate; the surface layer is made of blended natural fiber and synthetic fiber impregnated with modified nanoemulsion.

[0050] The preparation method of the antibacterial fiber of the present embodiment may comprise the f...

Embodiment 3

[0061] The antibacterial and anti-ultraviolet fabric of the present embodiment comprises a base cloth layer, a moisture-absorbing layer, a grid air-permeable layer and a surface layer; On, the sunscreen layer is set on the mesh air-permeable layer.

[0062] The base fabric layer is made by interweaving warps and wefts perpendicular to each other, the warps are antibacterial fibers, the wefts are composed of flax fibers and vinylon fibers in a weight ratio of 1:3, the diameter of the warps is 51 microns, the diameter of the wefts is 45 microns, and the warps The density is 79 threads / cm, and the weft thread density is 55 threads / cm;

[0063] The antibacterial fiber is modified cellulose acetate with antibacterial monomer grafted on the side chain of cellulose acetate; the surface layer is made of blended natural fiber and synthetic fiber impregnated with modified nanoemulsion.

[0064] The preparation method of the antibacterial fiber of the present embodiment may comprise the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com