High fracture toughness paint surface protection film and applications thereof

A protective film and high-fracture technology, applied in the direction of pressure-sensitive film/sheet, polymer adhesive additive, film/sheet-shaped adhesive, etc., can solve the problem of easy residual glue and achieve high light transmittance and UV absorption rate, convenient for industrial production, and easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] A kind of preparation method of the paint protective film of high fracture toughness provided by the invention comprises the following steps:

[0073] a. Accurately weigh and add to the organic solvent according to the parts by weight of each component of the pressure-sensitive adhesive layer, and stir evenly to obtain the pressure-sensitive adhesive glue coating liquid;

[0074] b. Apply thermosetting self-repairing glue evenly on the upper surface of the substrate layer, and then bake in an oven at a temperature of 40-125°C. The thermosetting self-repairing glue forms self-repairing on the upper surface of the substrate layer layer to obtain a semi-finished paint protection film;

[0075] c. Coating the pressure-sensitive adhesive glue coating solution on the lower surface of the base material layer of the semi-finished product, and then entering the oven to bake at a temperature of 60-150°C. A pressure-sensitive adhesive layer is formed on the lower surface, and the...

Embodiment 1

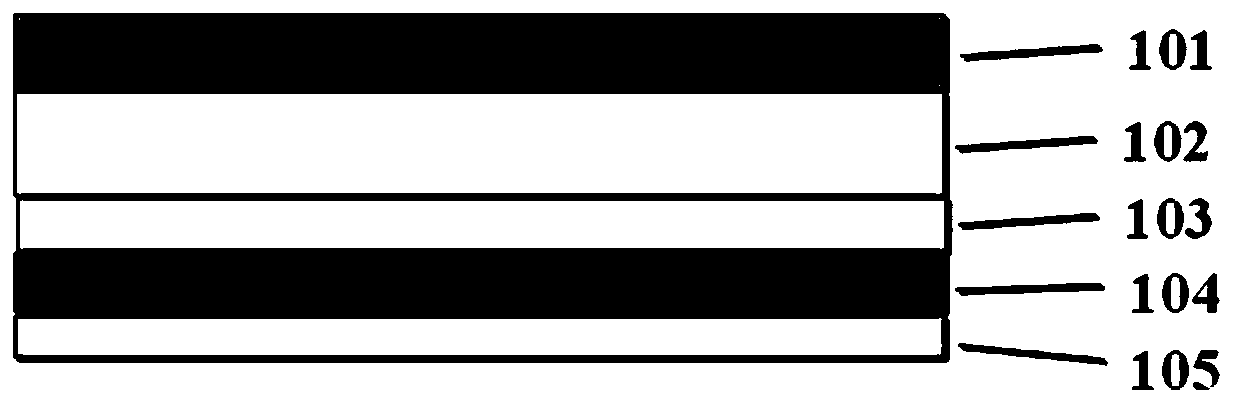

[0086] The invention provides a paint protection film with high fracture toughness. The paint protection film with high fracture toughness comprises a self-repairing layer, a base material layer and a pressure-sensitive adhesive layer; wherein one side of the base material layer is provided with the As for the self-healing layer, the other side of the substrate layer is provided with the pressure-sensitive adhesive layer.

[0087]The raw material of the pressure-sensitive adhesive layer is composed of the following materials: epoxy resin: 60 parts by weight; anhydride curing agent: 22 parts by weight; tackifying resin: 12 parts by weight; Qishi toughener: 4 parts by weight; Accelerator: 1 weight part; Antioxidant: 0.5 weight part;: Ultraviolet absorber 0.5 weight part; Wherein epoxy resin is bisphenol F type epoxy resin; Anhydride curing agent is dodecyl succinic anhydride; The toughening agent is QS-N; the epoxy accelerator is triethanolamine; the tackifying resin is polyisob...

Embodiment 2

[0094] The raw material of the pressure-sensitive adhesive layer of the paint protection film with high fracture toughness as described in Example 1 is made up of following materials: epoxy resin: 35 parts by weight; Anhydride curing agent: 10 parts by weight; Tackifying resin: 28 parts by weight Parts; Qishi toughening agent: 13 parts by weight; Epoxy accelerator: 10 parts by weight; Antioxidant: 1.0 parts by weight; Ultraviolet absorber: 3.0 parts by weight; Wherein the epoxy resin is a resorcinol type epoxy resin; Anhydride curing agent is tetrahydrophthalic anhydride; Qishi toughening agent is QS-VE; epoxy accelerator is: DMP-30; tackifying resin is terpene-phenol resin; antioxidant is phosphite; The absorber is formamidine UV absorber. Wherein, the equivalent ratio of the epoxy group of the epoxy resin and the anhydride group of the anhydride curing agent in the raw material of the pressure-sensitive adhesive layer is 1.30.

[0095] Wherein, the organic solvent in the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com