Low-initial adhesion high-holding adhesion paint protective film and application thereof

A technology for protective film and paint surface, which is applied in the direction of adhesives, adhesive types, pressure-sensitive films/sheets, etc. It can solve the problems of large attenuation of holding force, low holding force, low initial tack, etc., and achieve sticking Effects of reduced force decay, low initial tack, and high holding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] A kind of preparation method of the paint protective film with low initial viscosity and high stickiness provided by the invention comprises the steps:

[0075] a. Accurately weigh and add to the organic solvent according to the parts by weight of each component of the pressure-sensitive adhesive layer, and stir evenly to obtain the pressure-sensitive adhesive glue coating liquid;

[0076] b. Apply thermosetting self-repairing glue evenly on the upper surface of the substrate layer, and then bake in an oven at a temperature of 40-125°C to form a self-repairing layer on the upper surface of the substrate layer to obtain a paint surface semi-finished protective film;

[0077] c. Coat the pressure-sensitive adhesive glue coating solution on the lower surface of the base material layer of the semi-finished product, and then bake in an oven at a temperature of 40-150°C to form a pressure-sensitive adhesive layer on the lower surface of the base material layer of the semi-fin...

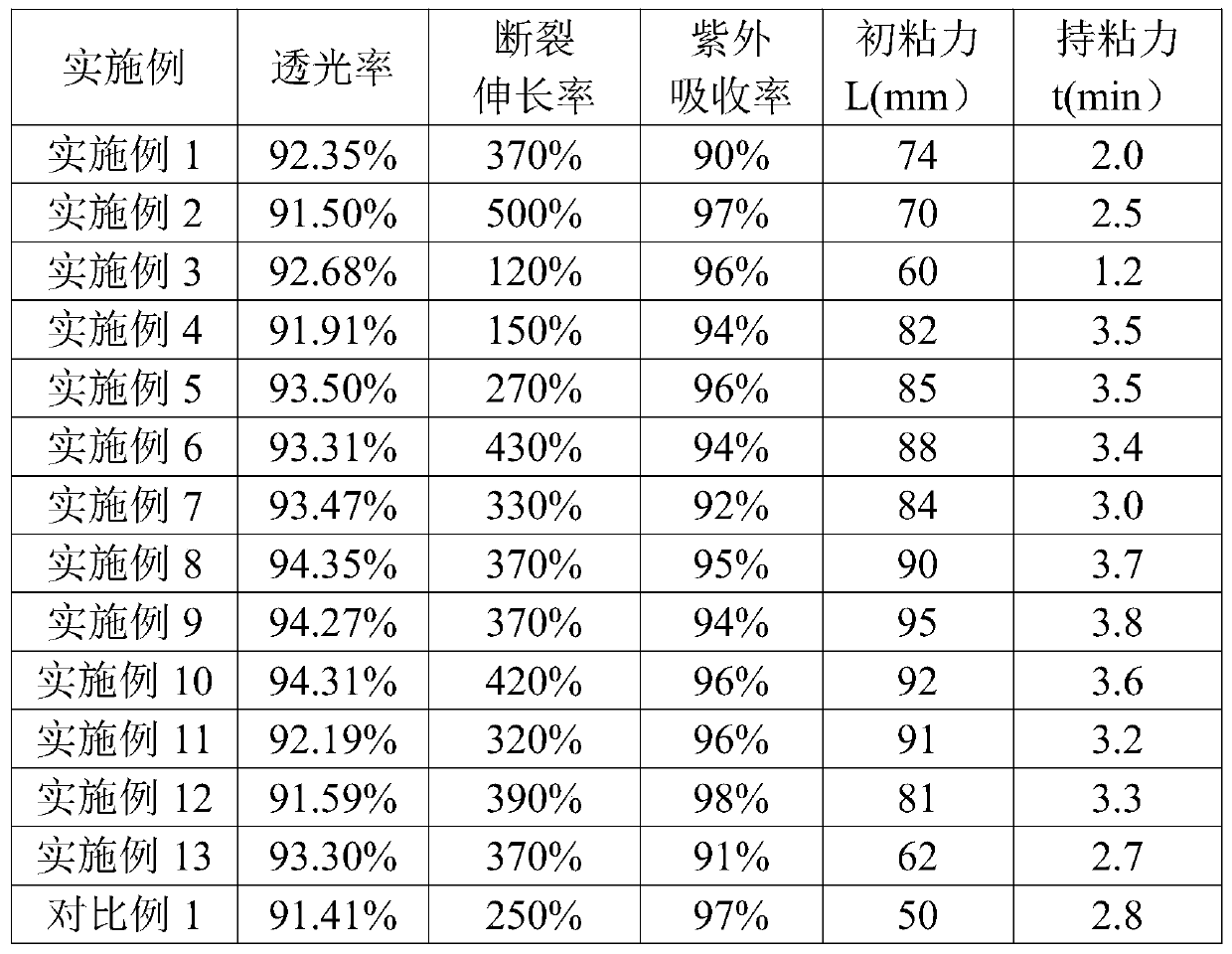

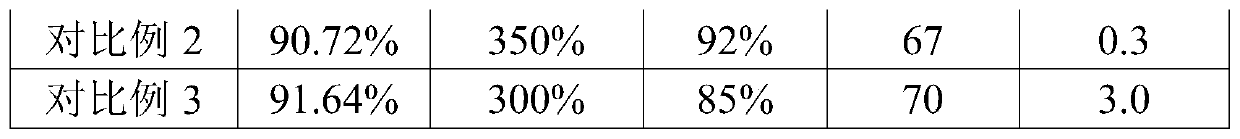

Embodiment 1

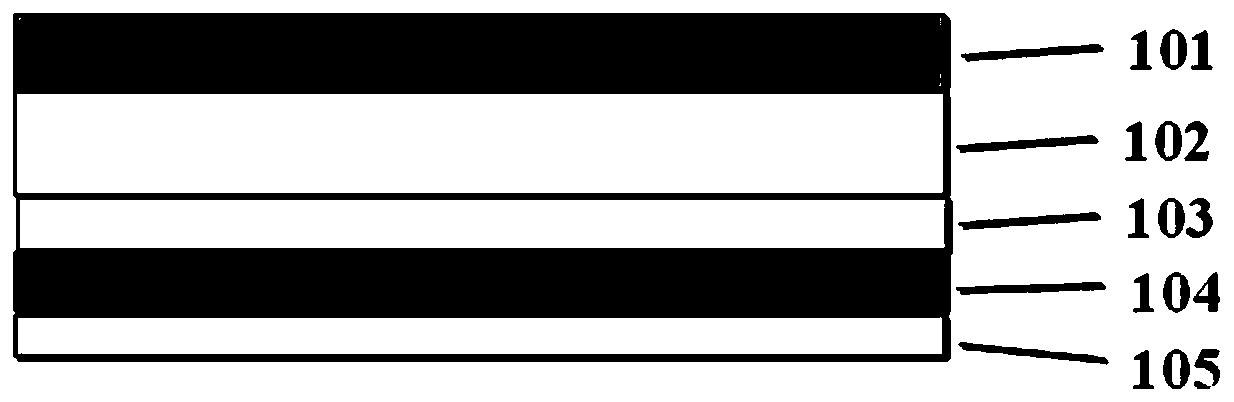

[0085] The present invention provides a low initial viscosity and high stickiness paint surface protection film and a preparation method thereof, wherein the low initial viscosity and high stickiness paint surface protection film comprises a self-repairing layer, a substrate layer and a pressure-sensitive adhesive layer; wherein The self-healing layer is provided on one side of the substrate layer, and the pressure-sensitive adhesive layer is provided on the other side of the substrate layer.

[0086] The raw material of the pressure-sensitive adhesive layer is composed of the following materials: crystalline hydroxyl polyurethane resin: 26 parts by weight; polyol resin: 36 parts by weight; crosslinking agent: 7 parts by weight; tackifying resin: 30 parts by weight; : 0.5 parts by weight; UV absorber: 0.5 parts by weight; wherein the crystalline hydroxyl polyurethane resin is UXP2702 of Covestro Company, and its crystallization time is 120h; the polyol resin is UXP2702 of Coves...

Embodiment 2

[0093] The raw material of the pressure-sensitive adhesive layer of the paint protective film with low initial viscosity and high stickiness described in Example 1 is made up of the following materials: crystalline hydroxyl polyurethane resin: 15 parts by weight; polyol resin: 55 parts by weight; Joint agent: 2 parts by weight; Tackifying resin: 24 parts by weight; Antioxidant: 1.0 parts by weight; Ultraviolet absorber: 1.0 parts by weight; Wherein the crystalline hydroxyl polyurethane resin is 213-1 of Covestro Company, and its crystallization time is 55h; the polyol resin is AV 2113 of Covestro, and its number average molecular weight is 1650; the crosslinking agent is hexamethylene diisocyanate (HDI); the tackifying resin is terpene-phenol resin; Phosphate ester; UV absorber is formamidine UV absorber. Wherein, the molar ratio of hydroxyl groups to isocyanate groups in the raw material of the pressure-sensitive adhesive layer -OH / -NCO=1.30.

[0094] Wherein, the organic so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com