ASP ternary composite oil displacing agent

A technology of ternary compound and oil displacement agent, applied in the field of oil displacement agent, can solve the problems of low stability of ternary compound flooding, low recovery rate, low salt and high temperature resistance, etc., and achieve excellent crude oil emulsifying ability , the effect of increasing the recovery rate and improving the temperature and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

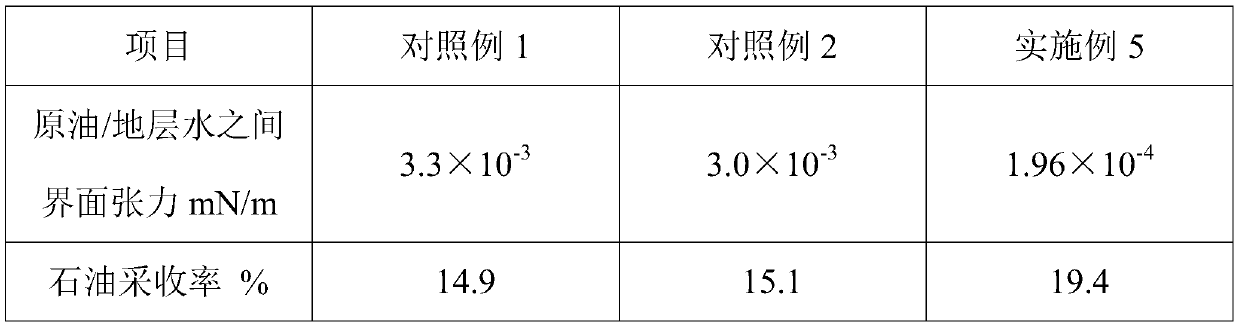

Examples

Embodiment 1

[0019] An ASP ternary composite oil displacement agent, the raw materials of which include by weight: 0.8 parts of polyacrylamide, 13.5 parts of surfactant, 3.5 parts of sodium silicate, 8 parts of ethanol, and 55 parts of water.

Embodiment 2

[0021] An ASP ternary composite oil displacement agent, its raw materials include by weight: 0.6 parts of polyacrylamide, 15 parts of surfactant, 3 parts of sodium silicate, 10 parts of ethanol, and 50 parts of water;

[0022] Among them, in the preparation process of polyacrylamide, 2-acrylamido-2-methylpropanesulfonic acid, N,N-dimethylacrylamide, acrylamide, arachidonic acid are added to N,N-dimethyl Mix in dimethylformamide, raise the temperature to 90°C, stir for 30 minutes, add the N,N-dimethylformamide solution of azobisisobutyronitrile dropwise in nitrogen atmosphere, keep stirring during the dropping process, within 60 minutes After the dropwise addition, continue to keep warm and stir for 3 hours, cool down to room temperature, stir continuously during the cooling process, add diethyl ether to settle, take the sediment, add methanol to dissolve, add diethyl ether to settle, filter to take the filter cake, and vacuum dry to obtain polyacrylamide, wherein, 2 - The weig...

Embodiment 3

[0024] An ASP ternary composite oil displacement agent, its raw materials include by weight: 1 part of polyacrylamide, 12 parts of surfactant, 4 parts of sodium silicate, 5 parts of ethanol, and 60 parts of water;

[0025] Among them, in the preparation process of polyacrylamide, 2-acrylamido-2-methylpropanesulfonic acid, N,N-dimethylacrylamide, acrylamide, arachidonic acid are added to N,N-dimethyl Mix in dimethylformamide, raise the temperature to 80°C, stir for 60 minutes, add the N,N-dimethylformamide solution of azobisisobutyronitrile dropwise in a nitrogen atmosphere, keep stirring during the dropping process, within 30 minutes After the dropwise addition, continue to keep stirring for 4 hours, cool down to room temperature, stir continuously during the cooling process, add diethyl ether to settle, take the sediment, add methanol to dissolve, add diethyl ether to settle, filter to take the filter cake, and vacuum dry to obtain polyacrylamide, wherein, 2 - The weight rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com