FeCoNiBOx/PPy/rGO nanomaterial, and OER electrocatalytic modified electrode based thereon

A nanomaterial and electrode modification technology, applied in the field of electrochemical catalysis, can solve the problems of scarcity, high price, poor stability, etc., and achieve the effects of fast reaction speed, low price and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

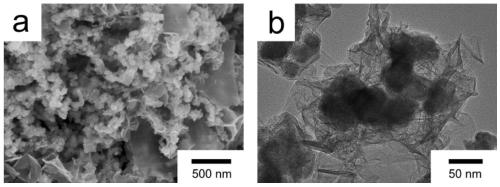

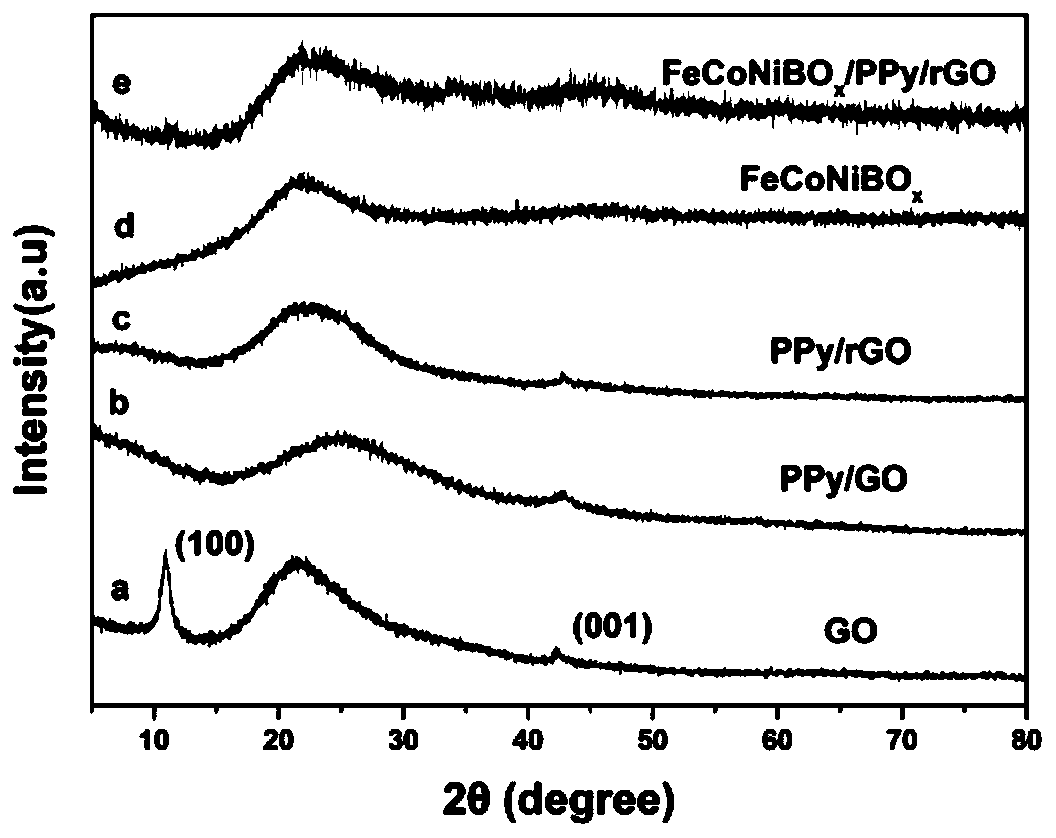

[0034] Example 1 FeCoNiBO x / PPy / rGO nanomaterials

[0035] (1) The preparation method is as follows:

[0036] 1) Preparation of GO nanosheets: Add 67.5mL of concentrated sulfuric acid, 2.0g of high-purity graphite and 1.6g of NaNO into a three-neck flask 3 , and stir evenly, keep the system temperature below 5°C, add 9g KMnO to the mixed solution within one hour 4 , and then placed in a 36°C water bath for 0.5h. After standing at room temperature for two weeks, dilute with 560 mL of 60°C water, add H 2 o 2 Until the solution turns bright yellow, centrifuge (rmp=10000) while it is hot, wash to neutrality, and vacuum-dry at 50° C. to obtain GO nanosheets.

[0037] 2) PPy / GO nanosheets: Add 0.2g GO nanosheets to 100mL deionized water for ultrasonic dispersion, then add 0.2g pyrrole (Py), add 0.6g FeCl after ultrasonic dispersion 3 ·6H 2 O, continue to sonicate for 0.5h, centrifuge, wash and dry in vacuum to obtain PPy / GO nanosheets.

[0038] 3) FeCoNiBO x Preparation of...

Embodiment 2

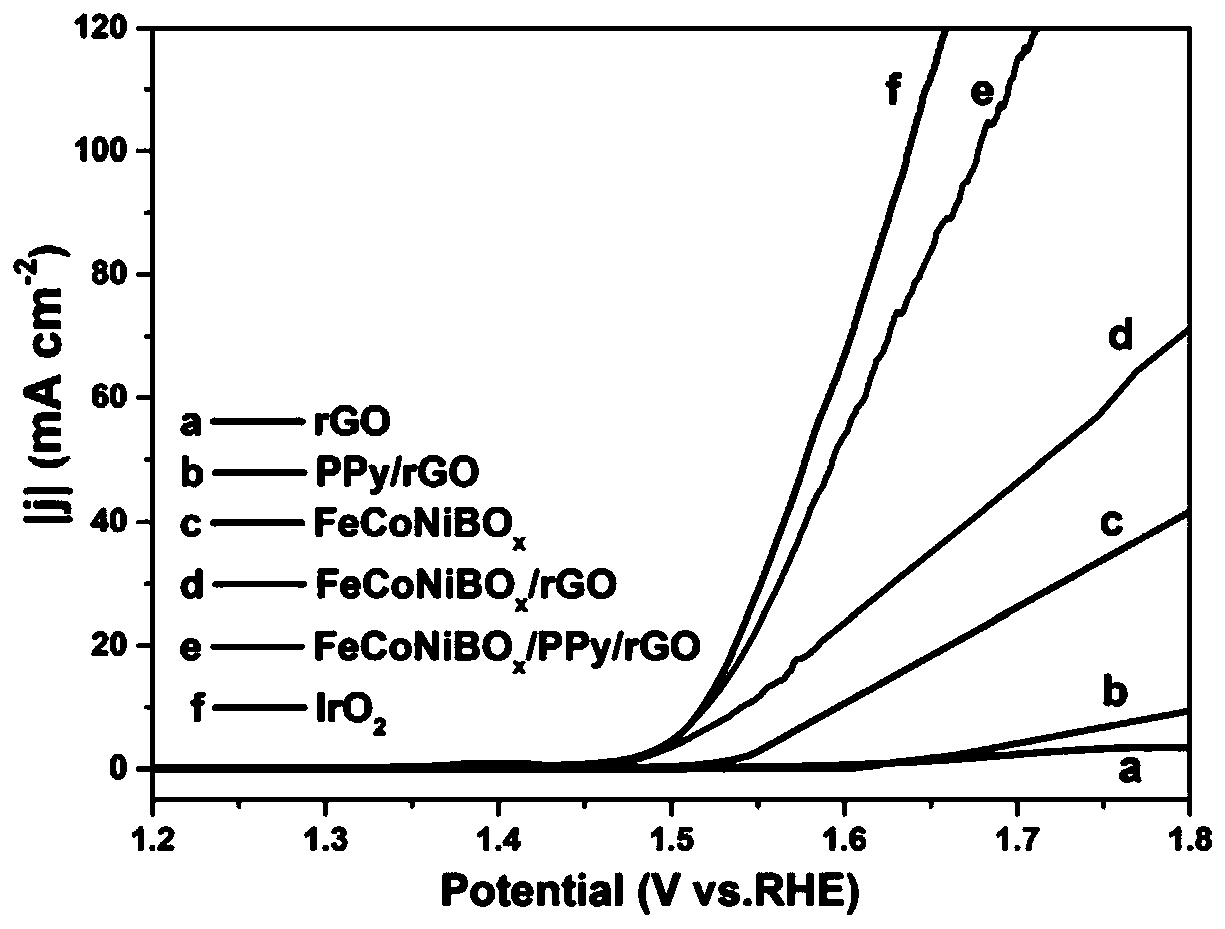

[0044] Example 2 Based on FeCoNiBO x OER Electrocatalytic Modification Electrode of / PPy / rGO Nanomaterials

[0045] (1) The preparation method is as follows:

[0046] 1) get the dry FeCoNiBO prepared by 2mg embodiment 1 x / PPy / rGO nanomaterials, add 1mL of ethanol, ultrasonically disperse for 20min, and obtain a black suspension with a concentration of 2mg / mL, which is the composite modifier, and set aside.

[0047] 2) Electrode treatment: the glassy carbon electrode was first polished with 0.3 μM aluminum oxide suspension on a polishing cloth, then ultrasonically cleaned with deionized water, and then 0.05 μM aluminum oxide suspension Polish it to a mirror surface on a polishing cloth, and finally clean it ultrasonically with ethanol and deionized water, dry it with high-purity argon, and set it aside.

[0048] 3) Preparation of modified electrode: Use a microsampler to pipette 5 μL of the composite modifier prepared in step 1) and drop-coat it on the surface of a polished...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap