Heat-retaining and moisture-retaining mass concrete protective device and laying method

A technology of large-volume concrete and protective devices, which is applied in coastline protection, construction material processing, water conservancy projects, etc., can solve the problems of affecting the effect of thermal insulation and moisturizing maintenance, difficult to cover thermal insulation and moisturizing materials, and difficult to accurately control temperature difference, etc., to achieve laying Convenient and fast, real-time adjustment and monitoring of concrete temperature, easy and stable installation and laying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

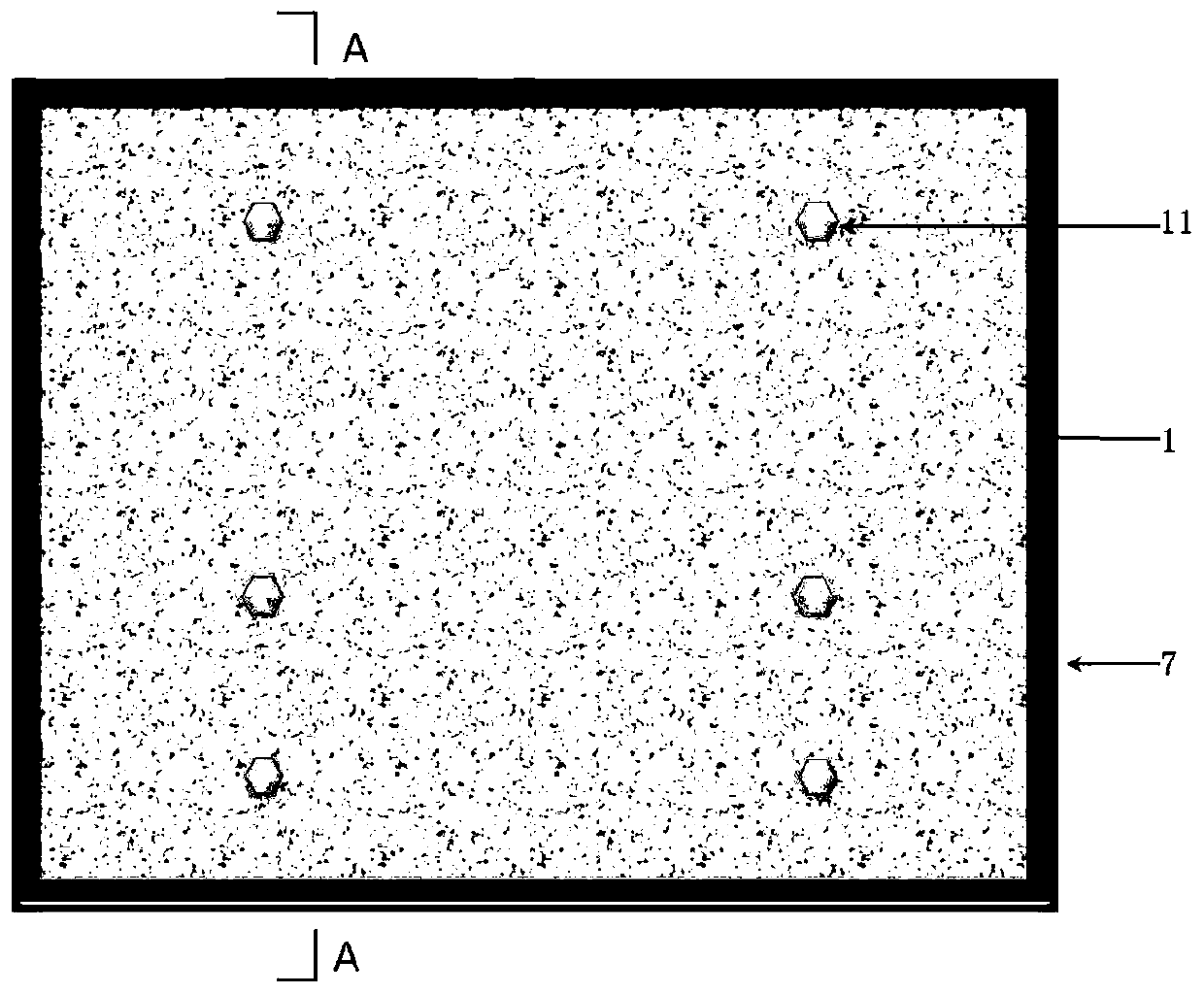

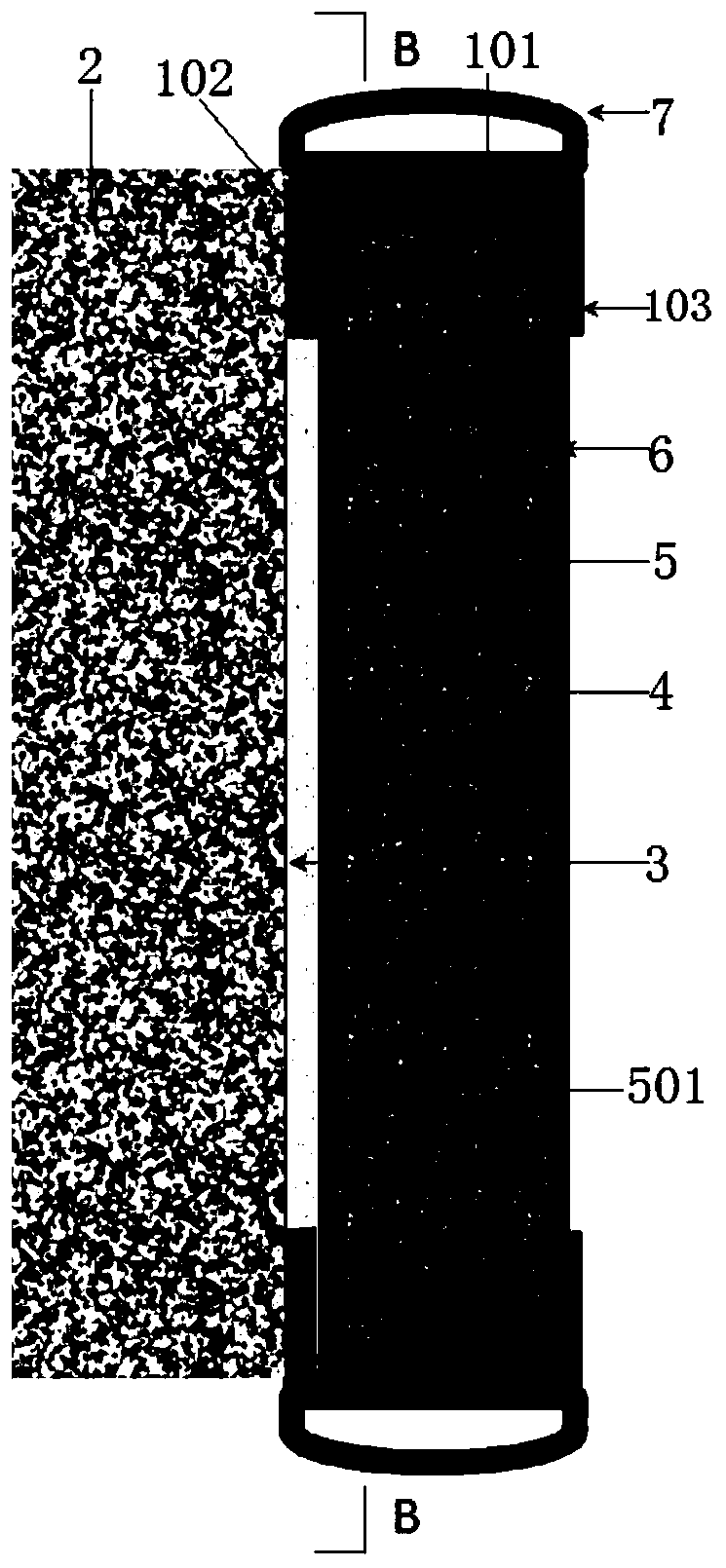

[0044] Such as figure 1 and figure 2 As shown, a large-volume concrete protective device with heat preservation and moisture retention includes a shaped frame 1 arranged on one side of the concrete 2, and the shaped frame 1 includes an outer frame 101 and first side plates on both sides of the outer frame 101 102 and a second side plate 103, the first side plate 102 is set close to the concrete 2; an active moisturizing layer 3, a first Water barrier coating 4, active insulation layer 5 and second water barrier coating 6;

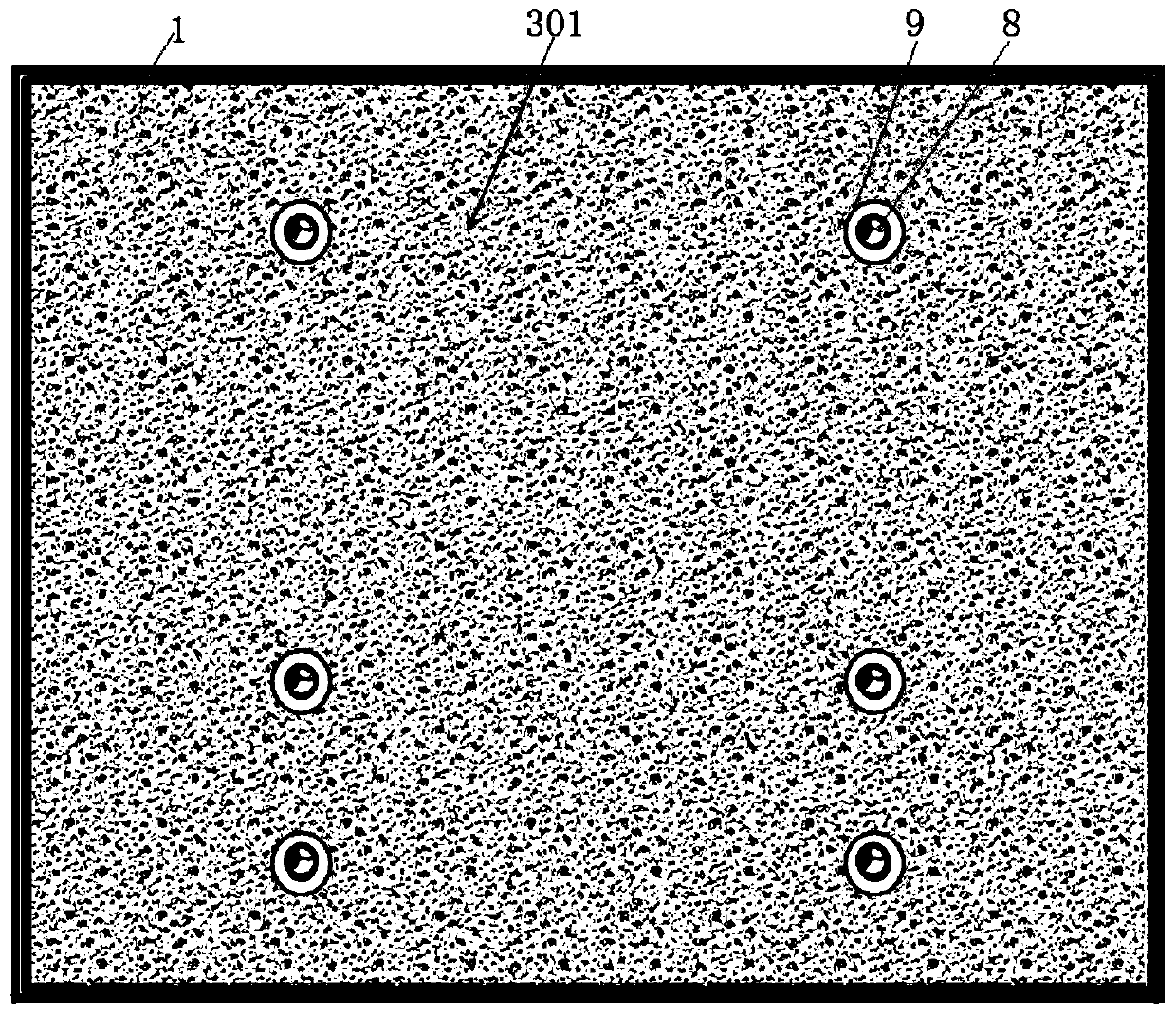

[0045] The active moisture retention layer 3 is close to the first side panel 102 around, as image 3 As shown, the active moisturizing layer 3 is a water storage material 301 laid between the first side panels 102, and the shaping frame 1 is provided with a number of water injection holes or water seepage holes on the side close to the concrete 2;

[0046] The active insulation layer 5 is a rock wool board arranged in the shaping frame 1, such as Fig...

Embodiment 2

[0056] Such as image 3 and Figure 5 As shown, the active moisture retention layer 3 is a saturated moisture retention layer; the water storage material 301 is a high water absorbent resin; the water injection hole 303 is set on the first side plate 102 and the outer frame 101 .

[0057] Preferably, a water storage tank 302 is provided between the outer frame 101 and the first side plate 102 ; one end of the water storage tank 302 is connected to the water storage material 301 , and the other end is connected to the water injection hole 303 . The water storage tank 302 can store more water for use by the water storage material 301 , and after the water storage tank 302 is filled with water, the frequency of external water addition can be reduced and repeated labor can be reduced.

[0058] Continuously supply water to the water storage material 301 through the water injection hole 303 to ensure that it is in a saturated state, which is conducive to the diffusion and penetrati...

Embodiment 3

[0060] A method for laying a large-volume concrete protective device with thermal insulation and moisture retention, comprising the following steps:

[0061] S1: if Figure 7 As shown, according to the large-volume concrete design and construction drawings, the concrete 2 is poured, and a tie block 13 and a tie bar 14 are set in the concrete 2, and a section of the tie bar 14 leaks outward and is fixedly installed with a tie bar screw 15;

[0062] S2: Prepare and fabricate protective devices, as follows:

[0063] S201: Assemble the outer frame 101 and the first side plate 102 of the shaped frame 1, reserve a water injection hole on the shaped frame 1, and clean the inside and outside of the shaped frame 1;

[0064] S202: Set up an active moisturizing layer 3 with a thickness of 0.1-0.2mm; prepare a water storage material 301, lay the water storage material 301 in the shaped frame 1, and connect the surroundings with the first side plate 102 of the shaped frame 1 Connect and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com