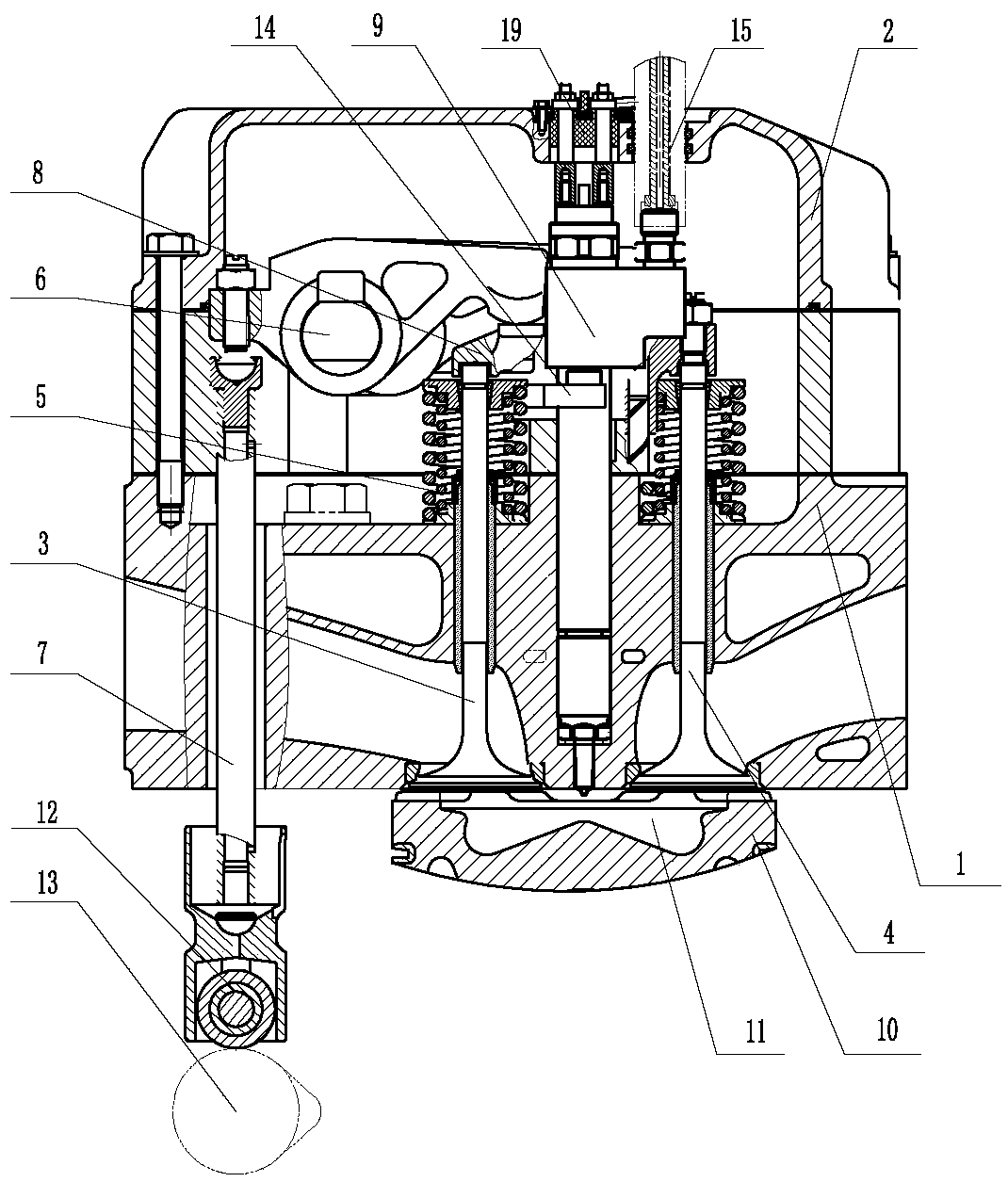

Wiring structure of electric control oil atomizer

A technology of electronically controlled fuel injection and wiring structure, which is applied to machines/engines, fuel injection devices, and engine sealing devices, etc. Simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

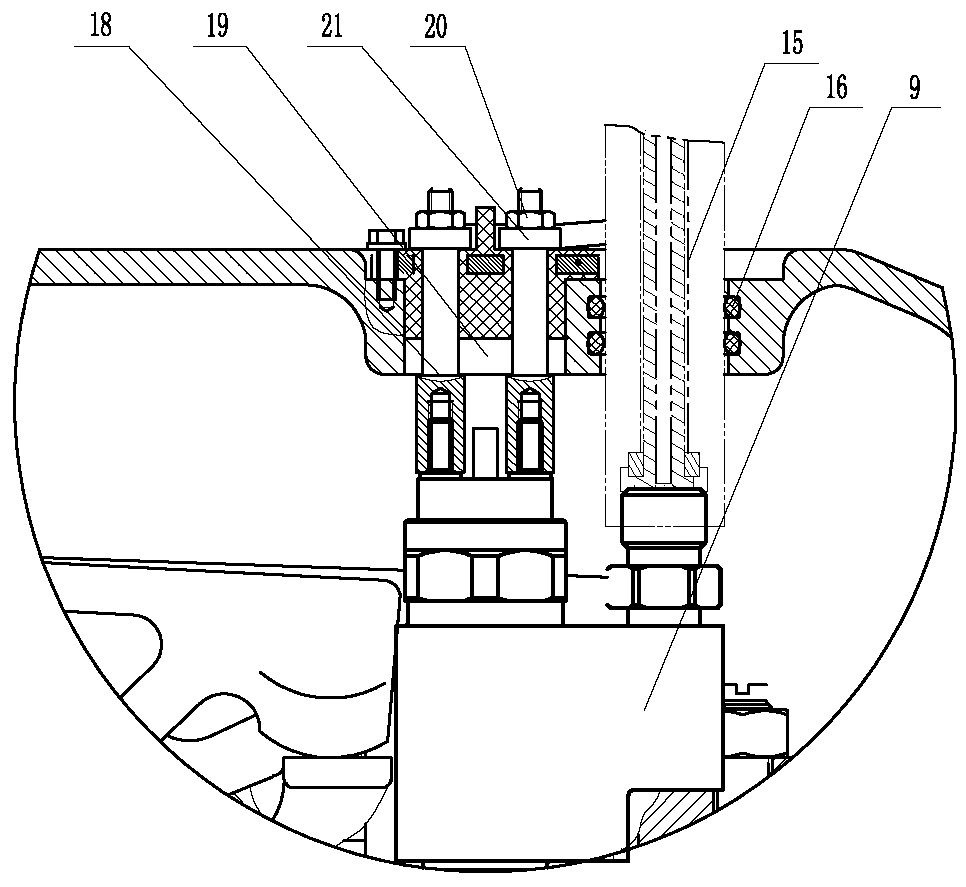

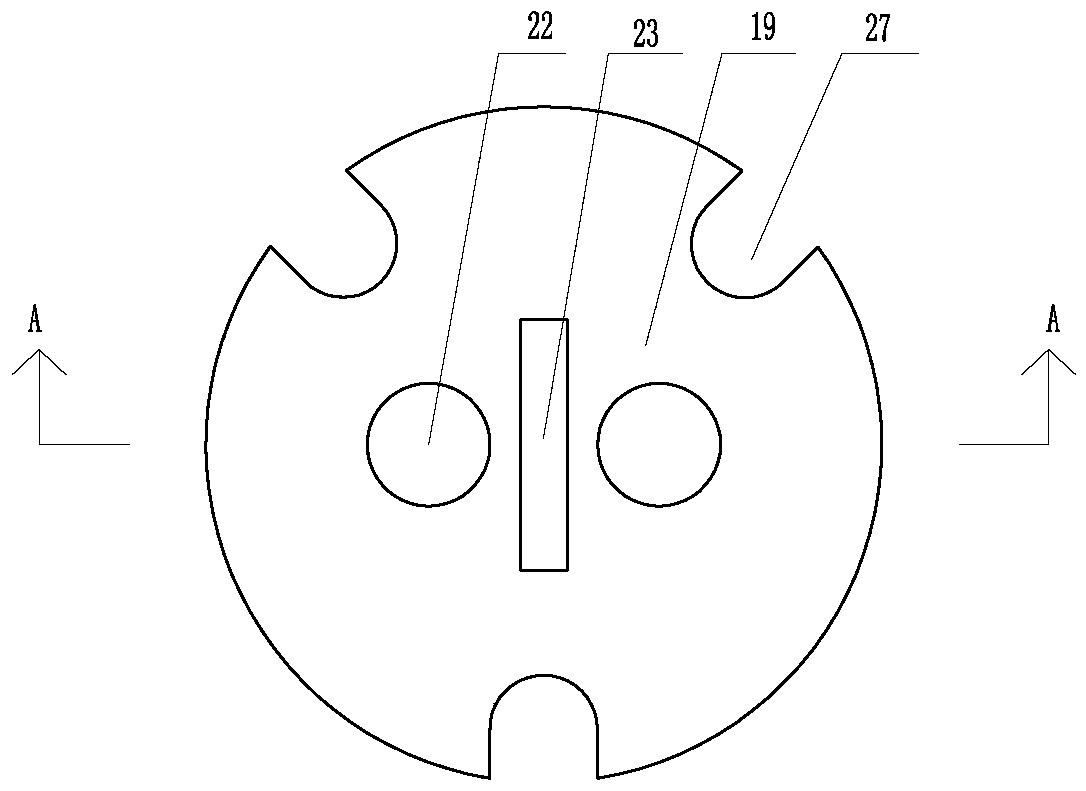

Embodiment 1

[0020] Embodiment 1: Two through-holes 22 that cooperate with the connecting studs 18 are opened on the sealing member 19, and a partition 23 located between the two through-holes 22 is installed on the upper surface of the sealing member 19; the connecting stud 18 includes a lower internal thread Connecting part 18-1, middle polished rod part 18-2, upper external thread connecting part 18-3, solenoid valve connecting post 17 are threadedly connected with lower internal thread connecting part 18-1, and the size of lower internal thread connecting part 18-1 is larger than that of through The inner diameter of the hole 22, the size of the upper external thread connection part 18-3 is smaller than the internal diameter of the through hole 88 and is exposed to the seal 19, and the upper external thread connection part 18-3 is equipped with a coupling piece 21 and a locking nut 20; the through hole The inner wall of 22 is a plane, and the outer surface of the middle polished rod por...

Embodiment 2

[0021] Embodiment 2: Two through-holes 22 cooperating with the connecting studs 18 are opened on the sealing member 19, and a partition 23 located between the two through-holes 22 is installed on the upper surface of the sealing member 19; the connecting stud 18 includes a lower internal thread Connecting part 18-1, middle polished rod part 18-2, upper external thread connecting part 18-3, solenoid valve connecting post 17 are threadedly connected with lower internal thread connecting part 18-1, and the size of lower internal thread connecting part 18-1 is larger than that of through The inner diameter of the hole 22, the size of the upper external thread connection part 18-3 is smaller than the internal diameter of the through hole 88 and is exposed to the seal 19, and the upper external thread connection part 18-3 is equipped with a coupling piece 21 and a locking nut 20; the through hole The inner wall of 22 is provided with an inner sealing ring 25, and the inner diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com