Method for manufacturing solder mask layer of circuit board

A production method and circuit board technology, which is applied in the fields of printed circuit manufacturing, printed circuit, printed circuit secondary treatment, etc., can solve the problems of low pass rate, high energy consumption, complicated process, etc., and achieve simple process flow and ecological protection Environment, improve the effect of ion pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for manufacturing a circuit board solder mask, comprising the following steps in turn:

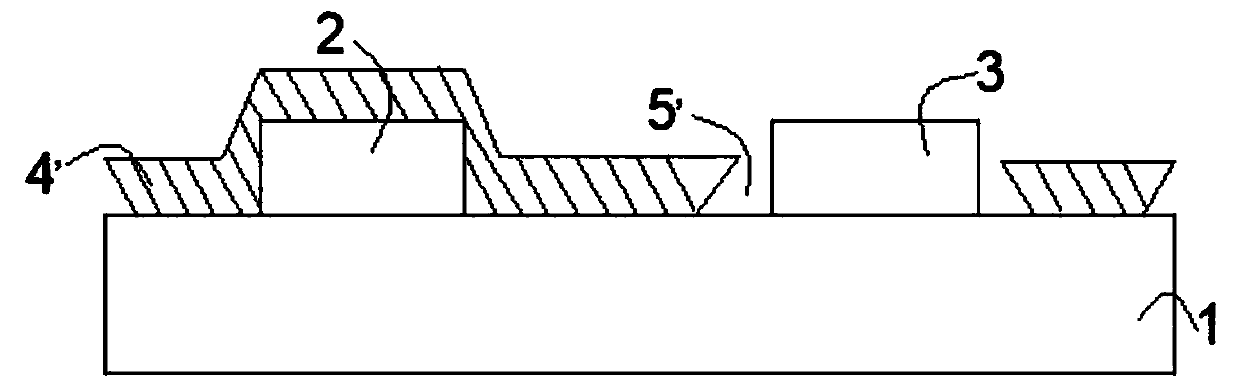

[0049] Filling ink: According to the information of CAM, printing technology is used to print the ink pattern between the circuit board and the pad, and cure the ink pattern with ultraviolet light; the filled ink is resin ink material; the thickness of the filled ink is the thickness of the line 50% of.

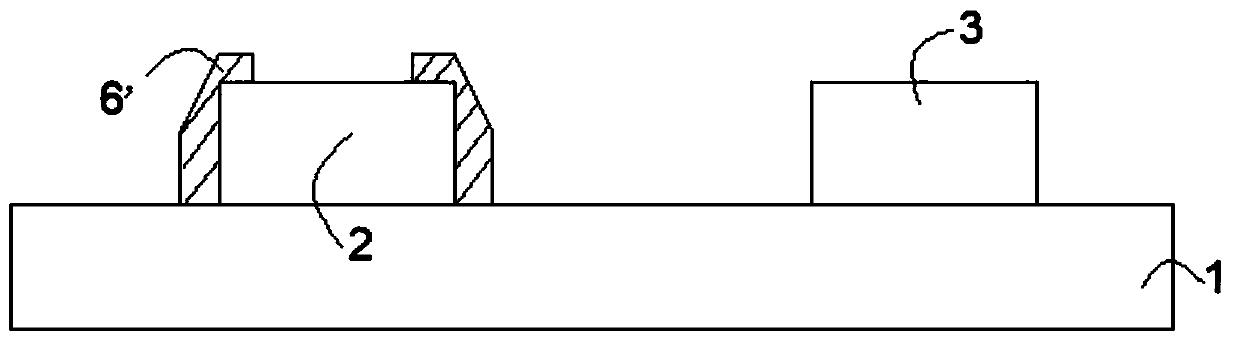

[0050] Pre-treatment of solder resist: including the step of grinding the plate; the step of grinding the plate is to use a grinding roller to grind off the ink dripping on the circuit and pad surface of the circuit board;

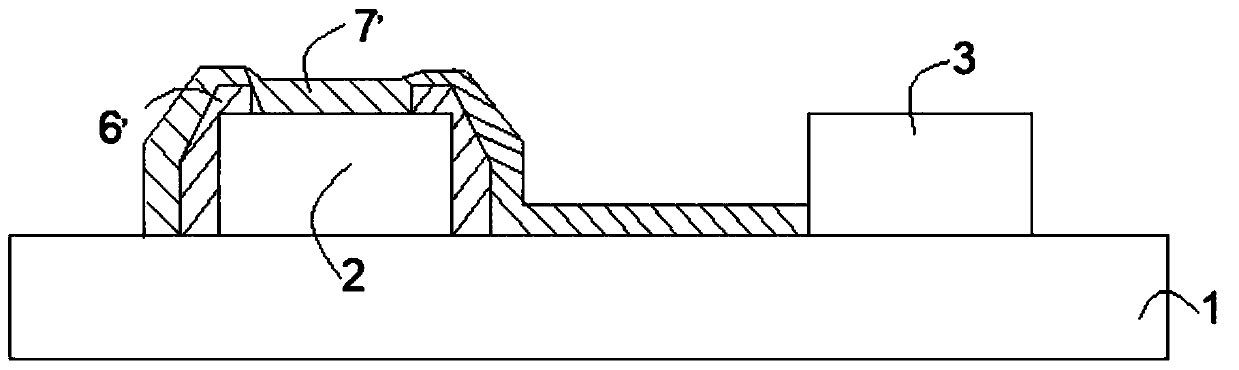

[0051] Solder masking steps: cover solder resist oil on the circuit board after solder mask pre-treatment; cover solder mask oil is based on CAM data, use printing technology to print the pattern of solder mask oil, and use the printed solder mask oil pattern UV light curing. On the substrate surface of the circuit board, after the solder resist is p...

Embodiment 2

[0056] A method for manufacturing a circuit board solder mask, comprising the following steps in turn:

[0057] Filling ink: According to the information of CAM, printing technology is used to print the ink pattern between the circuit board and the pad, and cure the ink pattern with ultraviolet light; the filled ink is resin ink material; the thickness of the filled ink is the thickness of the line 95% of.

[0058] Pre-treatment of solder resist: including the step of grinding the plate; the step of grinding the plate is to use a grinding roller to grind off the ink dripping on the circuit board and the surface of the pad;

[0059] Solder masking steps: cover solder resist oil on the circuit board after solder mask pre-treatment; cover solder mask oil is based on CAM data, use printing technology to print the pattern of solder mask oil, and use the printed solder mask oil pattern UV light curing. On the substrate surface of the circuit board, after the solder resist is print...

Embodiment 3

[0064] A method for manufacturing a circuit board solder mask, comprising the following steps in turn:

[0065] Filling ink: According to the information of CAM, printing technology is used to print the ink pattern between the circuit board and the pad, and cure the ink pattern with ultraviolet light; the filled ink is resin ink material; the thickness of the filled ink is the thickness of the line 65% of.

[0066] Pre-treatment of solder resist: including the step of grinding the plate; the step of grinding the plate is to use a grinding roller to grind off the ink dripping on the circuit and pad surface of the circuit board;

[0067] Solder masking steps: cover solder resist oil on the circuit board after solder mask pre-treatment; cover solder mask oil is based on CAM data, use printing technology to print the pattern of solder mask oil, and use the printed solder mask oil pattern UV light curing. On the substrate surface of the circuit board, after the solder resist is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com