Preparation method of titanium dioxide photocatalysis coating

A titanium dioxide and photocatalytic technology, applied in the field of photocatalytic materials, can solve the problems of reduced photocatalytic activity, low production efficiency, poor photocatalytic performance and stability of the coating, and achieve high catalytic efficiency, low equipment requirements, and good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

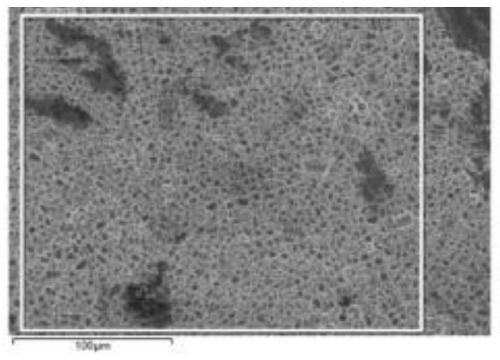

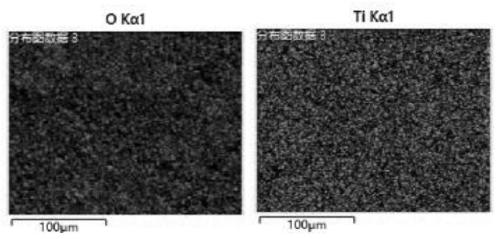

[0022] Figure 1 to Figure 4 Show a preferred embodiment of the preparation method of titanium dioxide photocatalytic coating of the present invention, it comprises the steps:

[0023] S1. Use acetone, absolute ethanol and deionized water to ultrasonically clean the surface of the titanium rod and fully dry it, and repeat the cleaning three times;

[0024] S2. Uniformly disperse the titanium dioxide nanopowder in the deionized aqueous solution, and form a stable suspension by vigorous stirring;

[0025] S3. Spray the suspension evenly on the surface of the titanium rod through the spray gun, and during the spraying process, the titanium rod rotates at a constant speed;

[0026] S4. The sprayed titanium rod is sprayed again after being baked, and the cycle is repeated, and the number of spraying and baking times is 10 times.

[0027] In this embodiment, the titanium rods in step S1 were cleaned by ultrasonic cleaning for 15 minutes with acetone, 15 minutes with absolute ethan...

Embodiment 1

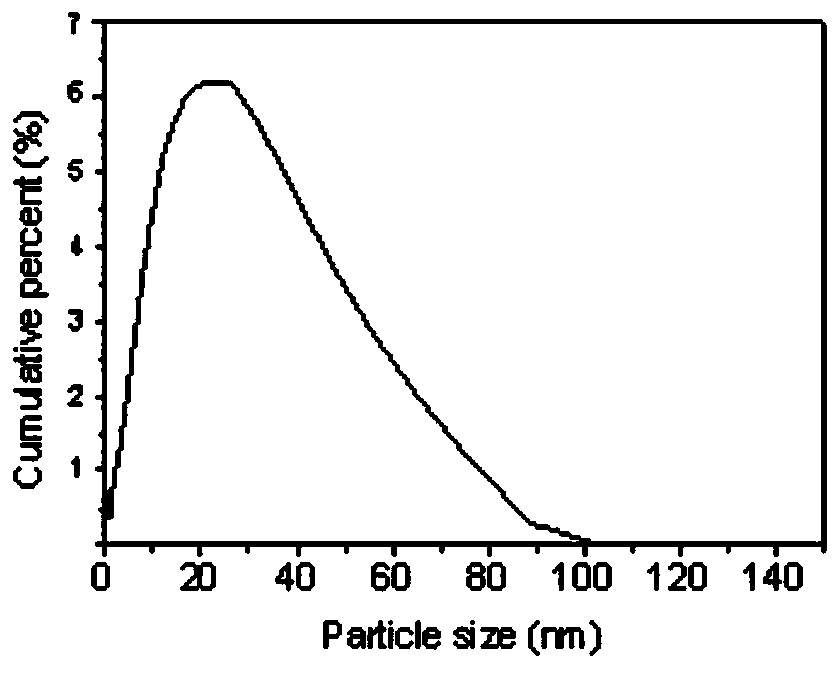

[0033] A titanium rod with a diameter of 3.0 mm and a length of 2.5 cm was placed in an ultrasonic cleaner, and washed with three solvents: acetone, absolute ethanol and deionized water in sequence, and cycled three times to completely remove surface pollutants. Fully disperse 15g of nanometer titanium dioxide in 100ml of deionized aqueous solution, and make the titanium dioxide stably suspended in the deionized aqueous solution by stirring vigorously. Use dispersant to help improve the dispersion effect of nano titanium dioxide in deionized water, but because titanium dioxide coating will be applied in the electric toothbrush, in order to avoid residual organic reagent, so adopt strong stirring in the present invention to improve the dispersion effect of nano titanium dioxide . Put the nano-titanium dioxide suspension into the spray gun, and spray it evenly on the surface of the titanium rod. During the spraying process, the titanium rod rotates at a speed of 180° / min, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com