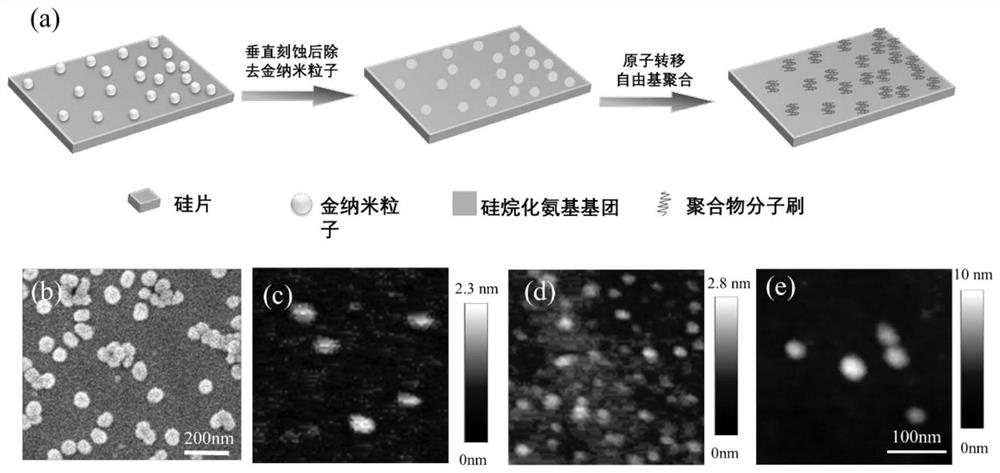

A method for preparing nano-sized polymer brush arrays using gold nanoparticles

A gold nanoparticle, nanometer-sized technology, applied in the field of material science, can solve the problems of complex instruments, high cost, etc., and achieve the effects of high repeatability, simple steps, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Cleaning and hydrophilic treatment of silicon substrate

[0025] Cut the monocrystalline silicon substrate (100) into a square with a side length of 2 cm with a glass knife, ultrasonically use acetone, ethanol, and deionized water for 5 minutes, and then place it in 98% concentrated sulfuric acid and 30% mass fraction. Heat and boil in a mixed solution of hydrogen peroxide (volume ratio 7:3) for 60 minutes to make the surface hydrophilic; wash the hydrophilic silicon substrate with deionized water repeatedly for 3 times, and store it in dehydrated ethanol for later use.

Embodiment 2

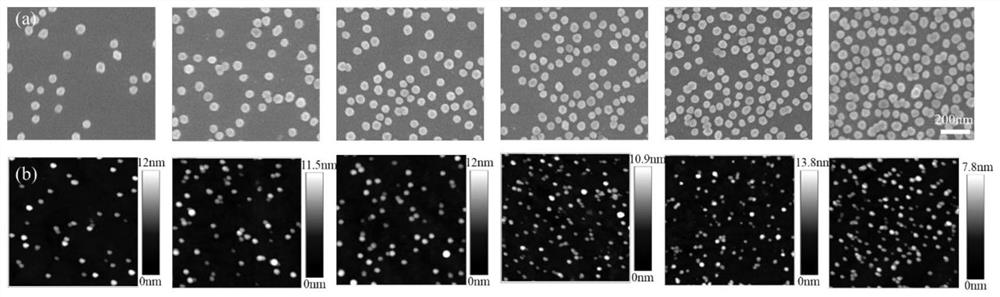

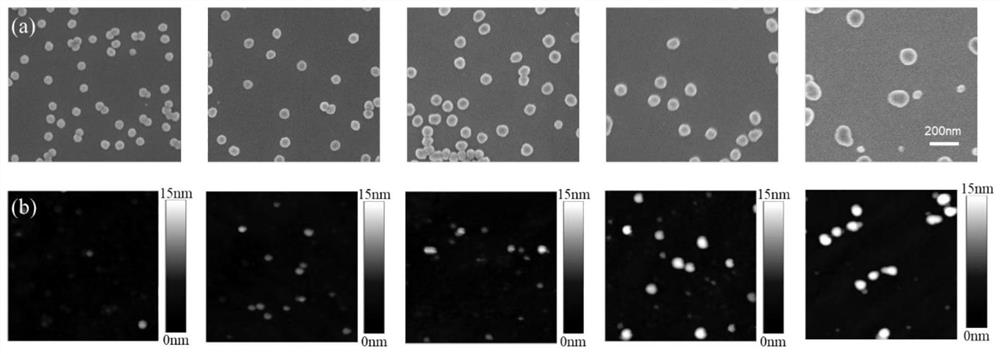

[0026] Example 2: Synthesis of gold nanoparticles of different sizes

[0027] Add 145mL deionized water and 5.5mL 60mmol / L sodium citrate aqueous solution into a 250mL three-necked flask, stir and heat to boiling. After boiling, the temperature was lowered to maintain a slightly boiling state, and 1045 μL of 1% chloroauric acid aqueous solution was added to react for 10 minutes to obtain gold nano-seeds. Cool the solution to 90°C, add 1045 μL mass fraction of 1% chloroauric acid aqueous solution, and react for 30 minutes; then add 1045 μL mass fraction of 1% chloroauric acid aqueous solution, react for 30 minutes, and pour out 75 mL of gold nanoparticles to obtain the first generation of gold nanoparticles. Particle sol; Repeatedly add 73mL deionized water and 2mL, 60mmol / L sodium citrate solution to the three-necked flask and heat to 90°C, add 1045μL mass fraction of 1% chloroauric acid aqueous solution, react for 30min; then add 1045μL mass fraction of 1% chloroauric acid a...

Embodiment 3

[0028] Embodiment 3: the preparation of surface amide silicon substrate

[0029] Take out the silicon substrate prepared in Example 1, place it in an oxygen plasma cleaning machine and clean it for 5 minutes, put it into a weighing bottle, and add 15 mL of γ-aminopropyltriethoxy with a volume fraction of 1%. Ethanol solution of silane, soak for 30min. Take out the substrate and clean it with absolute ethanol for 3 minutes under 50% power ultrasonic, then put it into an oven at 120° C. for 2 hours, take it out and cool it. In this step, an amination-modified silicon substrate is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com