Catalyst for co-producing low-carbon olefins from synthesis gas to gasoline and preparation method thereof

A technology for low-carbon olefins and synthesis gas, which is applied in catalyst activation/preparation, preparation of liquid hydrocarbon mixtures, chemical instruments and methods, etc., can solve the problems of low selectivity of low-carbon olefins and gasoline, etc. The effect of improving the surface alkalinity and improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

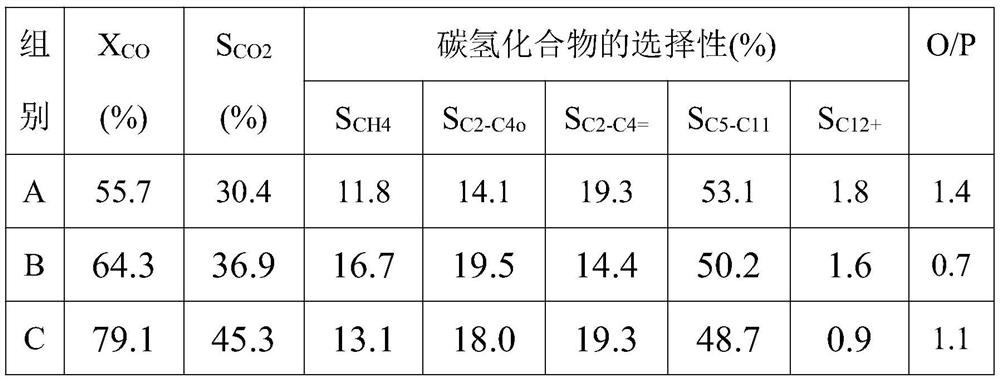

Examples

Embodiment Construction

[0021] The present invention will be specifically introduced below in conjunction with specific embodiments.

[0022] Part 1: Preparation of catalysts for syngas-to-gasoline co-production of low-carbon olefins

[0023] The catalyst for the co-production of low-carbon olefins from synthetic gas to gasoline provided by the invention, its preparation method comprises the following steps:

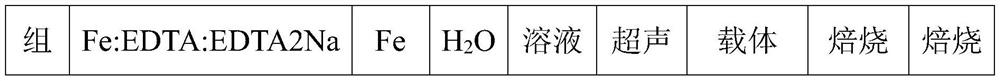

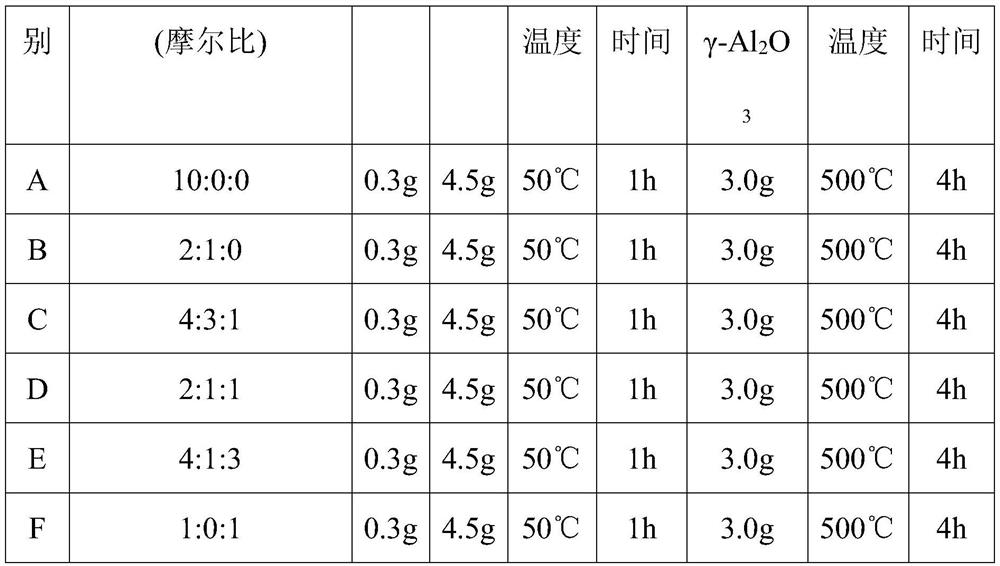

[0024] Step1: Prepare Fe-EDTA-EDTA2Na complex solution

[0025] Weigh a certain amount of ethylenediaminetetraacetic acid (EDTA), disodium ethylenediaminetetraacetic acid (EDTA2Na) and iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), and then added to an appropriate amount of deionized water (H 2 O), H 2 The amount of O is the carrier γ-Al 2 o 3 1.5 times of the weight, then the solution is heated to 50-60°C, and then ultrasonicated until a uniform Fe-EDTA-EDTA2Na complex solution without precipitation is formed, and the content of Fe in the Fe-EDTA-EDTA2Na complex solution is Carrier γ-A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com