Reaction method and catalyst system for selective oligomerization of ethylene, and application of catalyst system

A catalyst and selective technology, applied in the field of catalysis, can solve the problems of low total selectivity of 1-hexene and 1-octene and high activator dosage, and achieve low cost, low activator dosage, and total selectivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

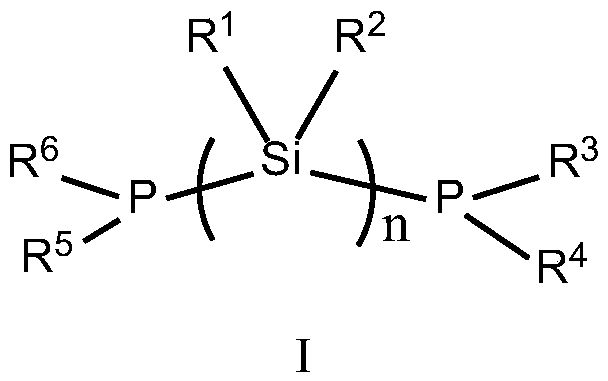

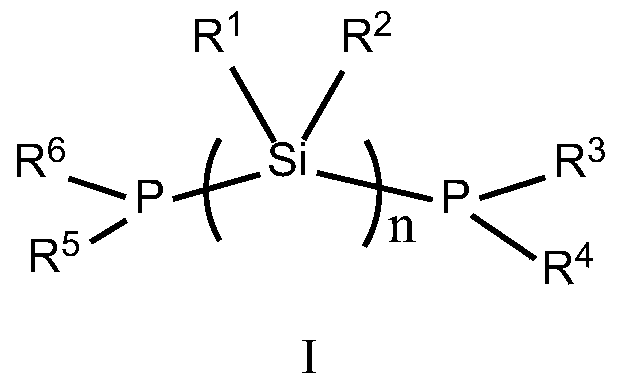

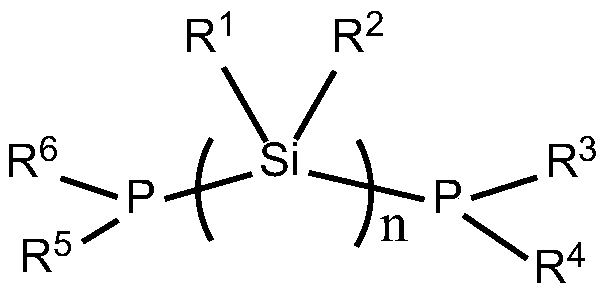

[0090] In an embodiment of the present invention, the preparation method of ligand a may include the following steps:

[0091] (1) Prepare R 5 R 6 PLi, R 3 R 4 PLi

[0092] Take a certain amount of R 5 R 6 PH, add a small amount of n-hexane and cool in the refrigerator for 10-20 minutes for later use. Take a certain amount of n-BuLi, add a small amount of n-hexane and put it in the refrigerator to cool for 10-15 minutes, then take out the above two medicines, slowly add n-BuLi dropwise into diphenylphosphine, let it rise to room temperature naturally, stir and react for about 12-24h, filter with a sand core funnel, wash twice with n-hexane, and get yellow R after vacuum drying 5 R 6 PLi solid.

[0093] R 3 R 4 The preparation method of PLi is the same as above.

[0094] (2) Preparation of R 5 R 6 P(R 1 SiR 2 ) n PR 3 R 4

[0095] A certain amount of Cl(R 1 SiR 2 ) n Cl was dissolved in n-hexane, and cooled in the refrigerator for 10-20 minutes for later ...

Embodiment 1

[0107] 1. Preparation of 1,2-bis(diphenylphosphineamine)-1,1,2,2-tetramethyldisilane ligand:

[0108] (1) Prepare R 5 R 6 PLi, R 3 R 4 PLi

[0109] Take 5.0 g of diphenylphosphine hydrogen, add a small amount of n-hexane and cool it in the refrigerator for 15-20 minutes for later use. Take 11.75mL of n-BuLi, add a small amount of n-hexane and cool it in the refrigerator for 10-15 minutes. Then the above two medicines were taken out, n-BuLi was slowly added dropwise into diphenylphosphine, naturally raised to room temperature, stirred and reacted for more than 12 hours, filtered with a sand core funnel, washed twice with n-hexane, and vacuum-dried to obtain 5.4g yellow LiPPh 2 solid.

[0110] (2) Preparation of R 5 R 6 P(R 1 SiR 2 ) n PR 3 R 4

[0111] Take 0.5g of tetramethyldichlorodisilane, add a small amount of n-hexane, and cool in the refrigerator for 10-15 minutes for later use. Take 1.0263g LiPPh 2 Add a small amount of n-hexane and put it in the refrig...

Embodiment 2

[0118] With embodiment 1. The difference is that R 2 For 2,4-dimethylphenyl. 113.9 g of the oligomerization product was obtained, and the catalyst activity was 6.90×10 6 g oligomer / mol Cr·h. The distribution of the oligomerization products is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com