a catalyst cuber 2 @uio-66-nh 2 -cf 3 cooh and its preparation method and application

A uio-66-nh2-cf3cooh, uio-66-nh2 technology, applied in the field of catalysts, can solve the problems of the catalyst system cannot be recycled, the trifluoroacetic acid cannot be recovered, the utilization rate is reduced, etc., and can be easily filtered or recovered by centrifugal separation. , the amount of catalyst is less, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

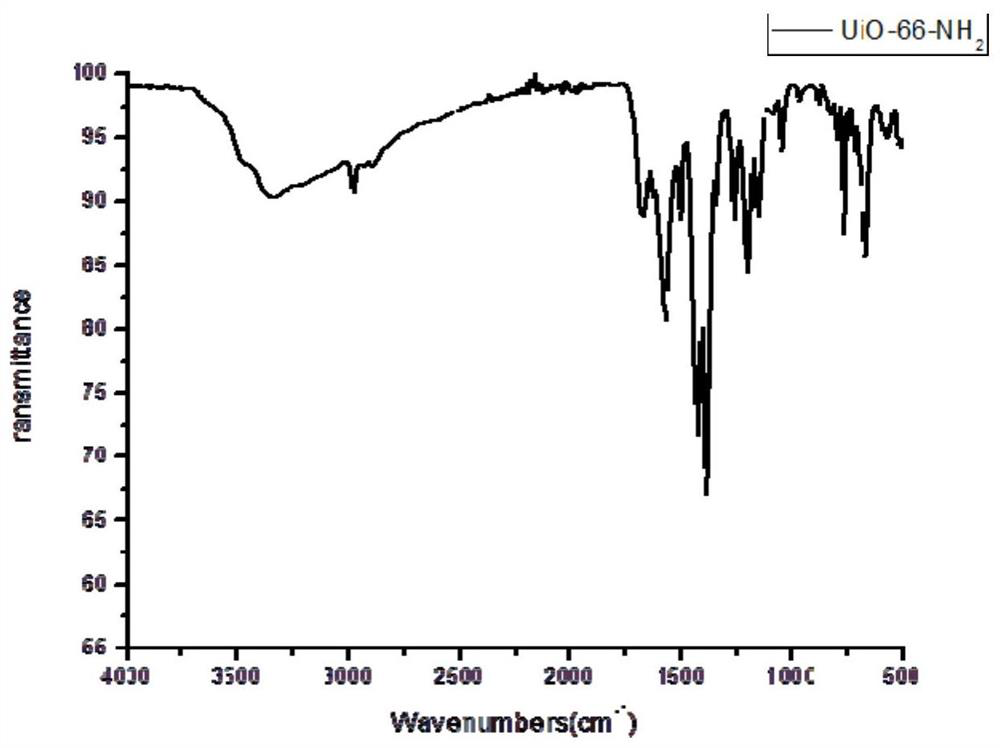

[0050] UiO-66-NH 2 The preparation comprises the following steps:

[0051] (1) ZrCl 4 (139mg, 0.6mmol) and CH 3 COOH (538μL, 9.4mmol) was dissolved in 15mL DMF solution, ultrasonically dispersed for 30min, after the solution was clarified, 2-aminoterephthalic acid (108mg, 0.6mmol) was added, and ultrasonically dispersed for 10min;

[0052] (2) Transfer the solution obtained after ultrasonic dispersion in step (1) to an autoclave, heat at 120°C for 24 hours, separate the reaction solution after completion, wash the obtained solid product three times with ethanol, and then heat it at 80°C Dry for 12h to get UiO-66-NH 2 95.0 mg, yield 89.7%.

Embodiment 2

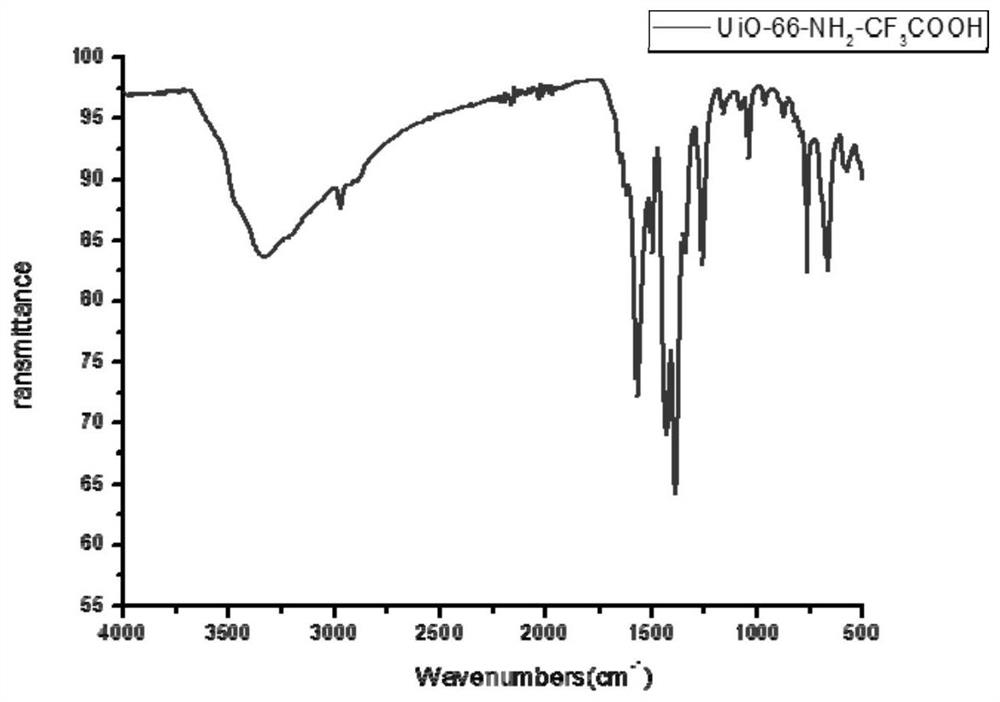

[0054] UiO-66-NH 2 -CF 3 The synthesis of COOH comprises the following steps: get the UiO-66-NH prepared in Example 1 2 20.0 mg, placed in 10 mL of CF with a concentration of 6 mol / L 3 After stirring in COOH aqueous solution for 12 hours, the reaction solution was separated after completion, and the obtained solid product was washed with ethanol three times, and then dried at 80°C for 12 hours to obtain UiO-66-NH 2 -CF 3 COOH.

Embodiment 3

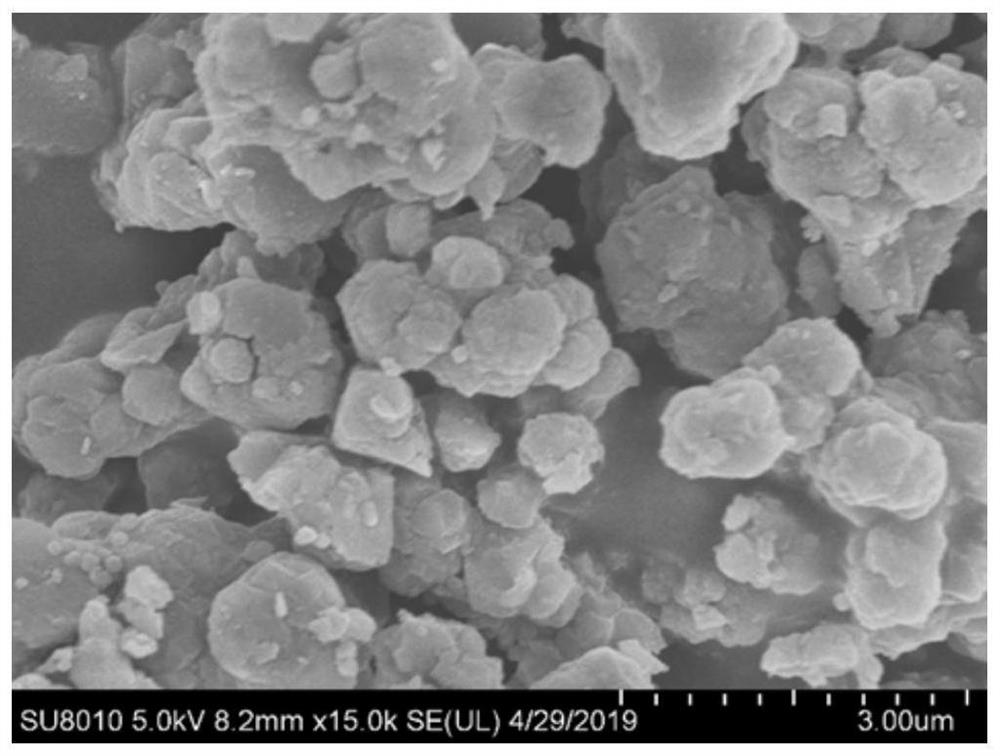

[0056] Catalyst CuBr 2 @UiO-66-NH 2 -CF 3 The preparation of COOH comprises the following steps: get the UiO-66-NH prepared by 10mg embodiment 2 2 -CF 3 COOH, add 8mL ethanol solution containing copper bromide (concentration: 5mg / mL), stir into a uniform turbid solution, soak for 12 hours, and centrifuge to obtain CuBr 2 @UiO-66-NH 2 -CF 3 COOH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com