Novel wear-resistant planetary grinding disc

A planetary grinding and wear-resistant technology, which is applied in the field of tools and planetary grinding discs, can solve the problems of inconsistency in processing size, achieve high product uniformity, increase wear resistance and hardness, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In conjunction with accompanying drawing, illustrate the concrete structure of each part of the present invention:

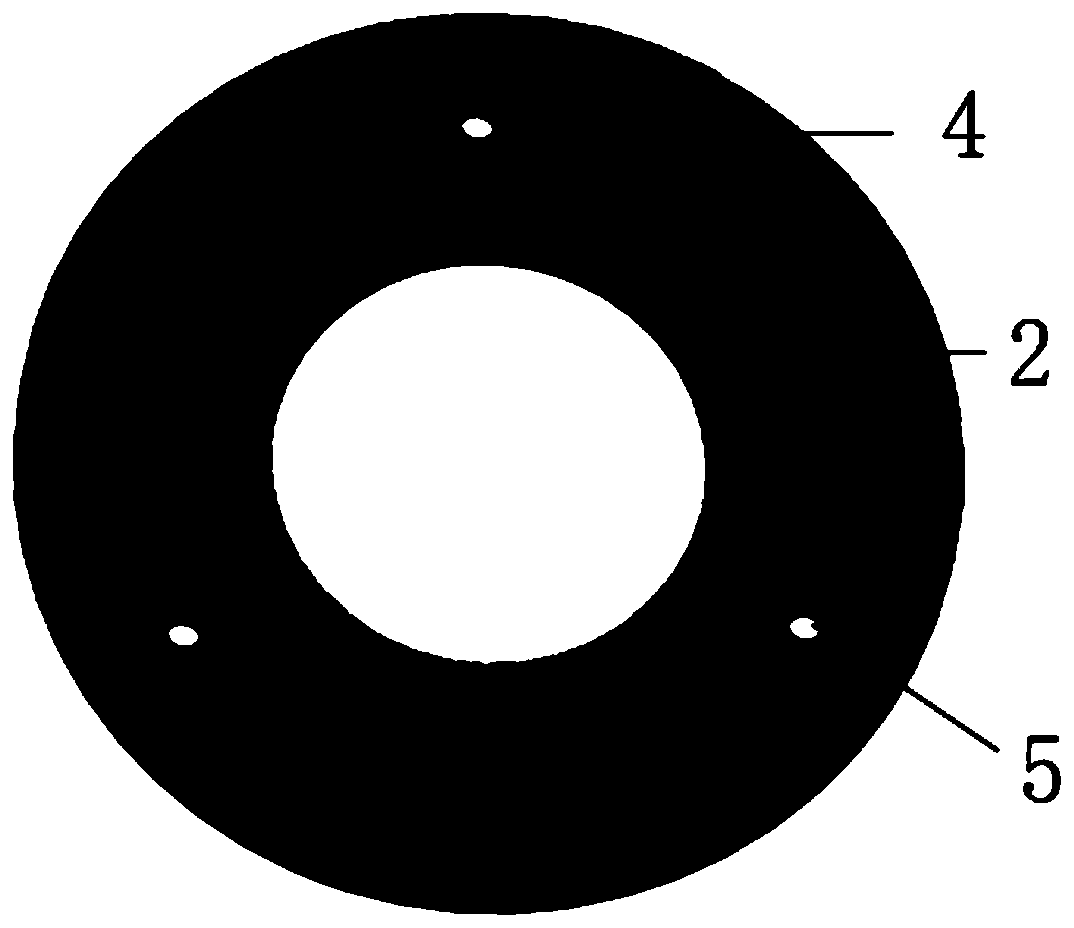

[0019] Will figure 1 The diamond composite sheet 4 with an outer diameter of 19.00 mm and a height of 5 mm is brazed on the grinding chassis 2. The outer diameter of the grinding chassis 2 is 250 mm, the inner diameter is 120 mm, and the thickness is 8 mm. The center of each counterbore is 110 mm away from the center of the grinding chassis 2. The diameter is 19.30mm, the counterbore depth is 3.0mm, and the number of counterbore holes is 24, evenly distributed on the same circle, such as image 3 . Will figure 2 The wear-resistant polytetrafluoroethylene plastic ring 3 with an outer diameter of 23 mm and an inner diameter of 19.30 mm is nested in the through hole of the grinding faceplate 1. The outer diameter of the grinding face plate is 290 mm, the inner diameter is 150 mm, and the thickness is 14 mm. The distance between the center of the circle a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com