Salt resistant and temperature resistant starch type drilling fluid loss agent and preparation method thereof

A filtrate reducer and starch technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulty in meeting performance requirements, avoid gelatinization and agglomeration, increase etherification degree, and reduce energy consumption little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

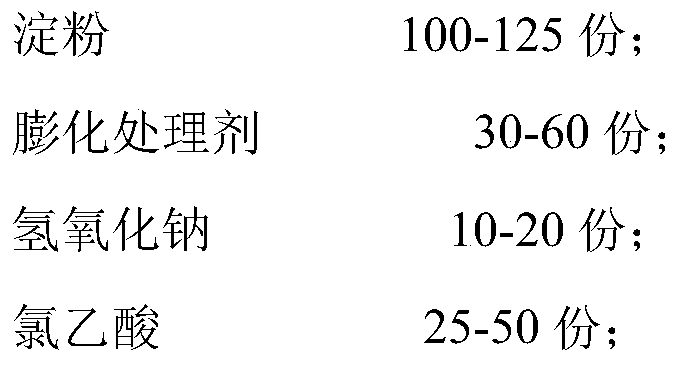

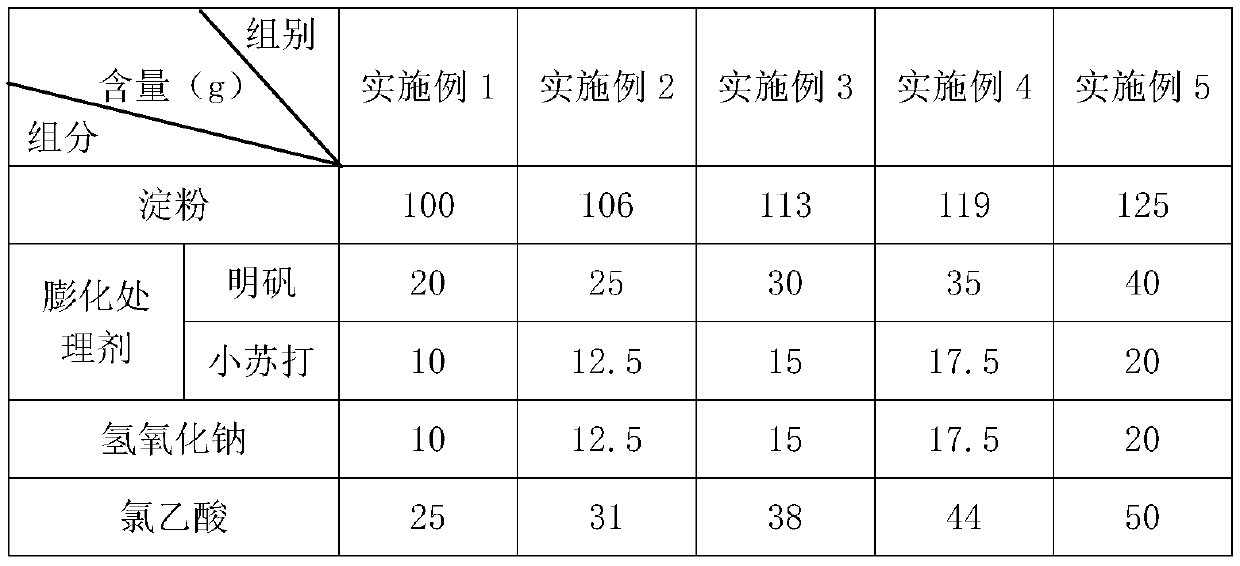

[0033]Embodiment 1: A salt-resistant and temperature-resistant starch drilling fluid loss reducer, its formula components and contents are as shown in Table 1 (1 parts by weight=1kg or 1 parts by weight=1g), the present embodiment uses 1 part by weight = 1 g as an example. Wherein the starch is cornstarch, the chloroacetic acid is a crystalline powder, and the sodium hydroxide is a flake solid. The preparation process of the salt-resistant and temperature-resistant starch drilling fluid loss reducer comprises the following steps:

[0034] S1. Starch pretreatment: Add starch to the reaction kneader at room temperature, add puffing treatment agent to the starch at a rate of v=1-1.2 parts / min while stirring, and always keep the added weight of alum and baking soda The ratio of the number of parts is 2:1, and the stirring time t1 is 30 minutes until the stirring and mixing are uniform to obtain the expanded starch;

[0035] S2. Starch alkalization: adding sodium hydroxide to the...

Embodiment 2

[0040] Embodiment 2: A salt-resistant and temperature-resistant starch-based fluid loss reducer for drilling wells. The difference between this embodiment and Embodiment 1 is that its formula components and their contents are as shown in Table 1 (1 parts by weight=1kg), t1 is 35min, and t2 is 75min.

Embodiment 3

[0041] Embodiment 3: A salt-resistant and temperature-resistant starch-based fluid loss reducer for drilling wells. The difference between this embodiment and Embodiment 1 is that its formula components and their contents are as shown in Table 1 (1 parts by weight=1kg), t1 is 40min, and t2 is 90min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com