Preparation method of sewage treatment flocculant

A sewage treatment and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of flocculation effect and degradability to be improved, flocculation effect and degradability to be improved, and poor flocculation effect, etc., to achieve good flocculation effect, good biodegradability, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

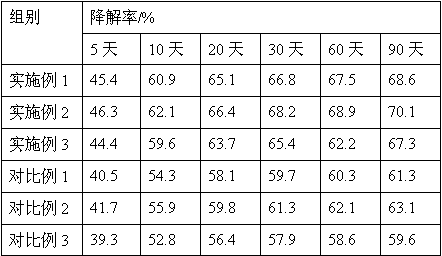

Examples

Embodiment 1

[0025] Example 1 A preparation method of flocculant for sewage treatment

[0026] S1 Wash 10 g of wheat bran residue with water for 4 times, add to 200 mL of acid mixture after natural air-drying, the acid mixture is composed of acetic acid and dilute sulfuric acid in a weight ratio of 1:2, leaching in a water bath for 1 hour, cooling and standing, and filtering to obtain Filter residue: wash the filter residue with water to neutrality, add in 100mL alkali mixed solution, the alkali mixed solution is composed of 0.5M sodium hydroxide and ammonia water in a weight ratio of 3:2, extract for 1h, filter, wash, and dry to obtain cellulose;

[0027] S2 Add 5 g of the cellulose obtained in step S1 into 5 mL of alkaline ionic liquid, stir and add 15 mL of sodium hydroxide solution, and stir evenly to obtain a cellulose solution; add the cellulose solution into a vacuum-sealed mold, and add 4 g of ether The etherifying agent is composed of methyl chloride and propylene oxide in a weig...

Embodiment 2

[0034] Example 2 A preparation method of flocculant for sewage treatment

[0035] S1 Wash 15g of wheat bran residue with water for 5 times, add to 225mL acid mixture after natural air-drying, the acid mixture is composed of acetic acid and dilute sulfuric acid in a weight ratio of 1:2, extract in a water bath for 1.5h, cool and stand, filter, Obtain filter residue; wash the filter residue to neutrality, add in 150mL alkali mixed liquor, described alkali mixed liquor is made up of 0.5M sodium hydroxide and ammonia water by weight ratio 3:2, leaching 1.5h, filter, wash, dry , get cellulose;

[0036] S2 Add 5 g of the cellulose obtained in step S1 into 8 mL of alkaline ionic liquid, and add 20 mL of sodium hydroxide solution with stirring, and stir evenly to obtain a cellulose solution; add the cellulose solution into a vacuum-sealed mold, and add 6 g of ether The etherifying agent is composed of methyl chloride and propylene oxide in a weight ratio of 1:3.5, reacted at 60°C for...

Embodiment 3

[0041] Example 3 A preparation method of flocculant for sewage treatment

[0042] S1 Wash 20g of wheat bran dregs with water for 5 times, add to 250mL acid mixture after natural air-drying, the acid mixture is composed of acetic acid and dilute sulfuric acid in a weight ratio of 1:2, extract in water bath for 2h, cool and stand still, filter to obtain Filter residue: wash the filter residue with water to neutrality, add in 200mL alkali mixed solution, the alkaline mixed solution is composed of 0.5M sodium hydroxide and ammonia water in a weight ratio of 3:2, extract for 2h, filter, wash, and dry to obtain cellulose;

[0043] S2 Add 5 g of the cellulose obtained in step S1 into 10 mL of alkaline ionic liquid, and add 25 mL of sodium hydroxide solution with stirring, and stir evenly to obtain a cellulose solution; add the cellulose solution into a vacuum-sealed mold, and add 8 g of ether The etherifying agent is composed of methyl chloride and propylene oxide in a weight ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com