Seawater-based fracturing fluid cross-linking agent, fracturing fluid and preparation method thereof

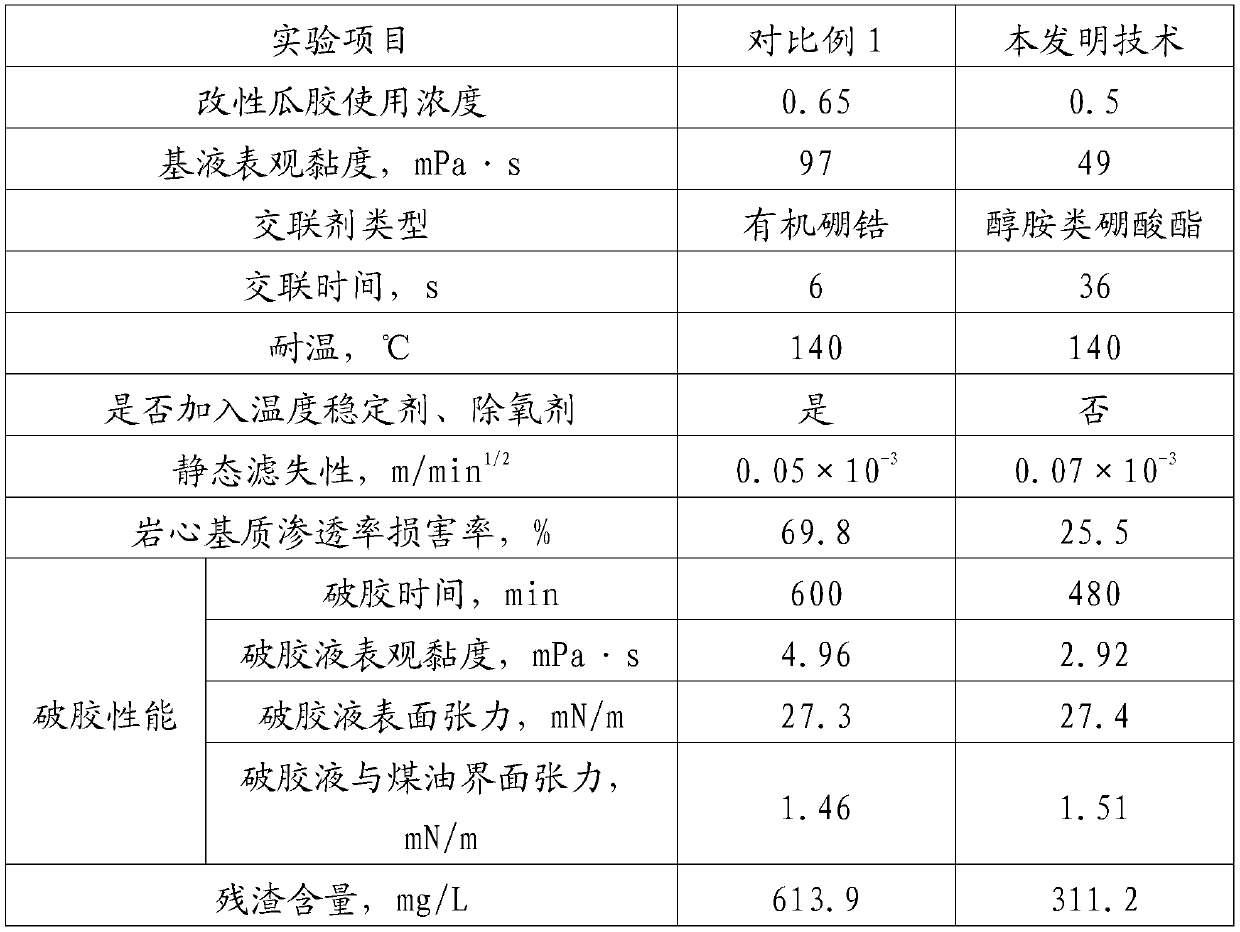

A technology of cross-linking agent and seawater, applied in the field of oil field fracturing fluid, can solve the problems of poor performance of cross-linking agent, high residue content and high viscosity, achieve optimal pH value buffering capacity, good temperature resistance performance, and small reservoir damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: The preparation method of the seawater-based fracturing fluid crosslinking agent, at room temperature, under stirring conditions, add 60kg of clean water, 35kg of triethanolamine borate, and 15kg of glycerin to the reaction kettle to fully mix; add 8kg to the mixture Boric acid, stir to make it fully react and dissolve to form a uniform solution to make a crosslinking agent. The triethanolamine borate is industrial grade. The boric acid has a content of 99%, industrial grade. The glycerin has a content of 99%, industrial grade. Same below.

Embodiment 2

[0017] Example 2: The preparation method of the seawater-based fracturing fluid crosslinking agent, at room temperature, under stirring conditions, add 40kg of clean water, 25kg of triethanolamine borate, and 10kg of glycerin to the reaction kettle and mix thoroughly in proportion; in the mixed solution Add 5kg of boric acid, stir to make it fully react and dissolve to form a uniform solution, and make a crosslinking agent.

Embodiment 3

[0018] Example 3: The preparation method of the seawater-based fracturing fluid crosslinking agent, at room temperature, under stirring conditions, add 50kg of clean water, 30kg of triethanolamine borate, and 15kg of glycerin to the reaction kettle and mix thoroughly in proportion; in the mixed solution Add 8kg of boric acid and stir to make it fully react and dissolve to form a uniform solution to make a crosslinking agent.

[0019] Embodiment 3 is the best embodiment, and it will be explained by taking Embodiment 3 as an example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com