Preparing method of composite energetic fragment with metal matrix on outer layer and polymer matrix on inner layer

A metal-based, polymer technology, applied in the field of energetic materials and active fragment materials, can solve the problems of low strength, density and activity, and achieve the effects of high strength, increased power and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

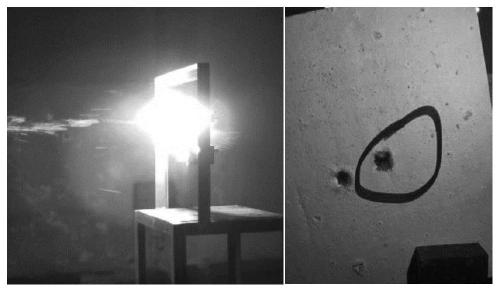

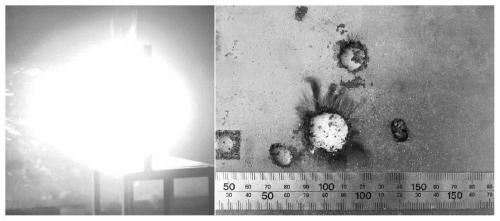

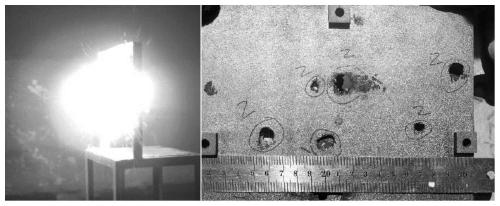

Image

Examples

Embodiment 1

[0026] A method for preparing a composite energetic fragment of an outer metal base and an inner polymer base, the specific steps are as follows:

[0027] (1) First prepare the outer metal-based hollow cylindrical specimen;

[0028] Weighing and powder mixing: the mass ratio of each component is: tungsten powder / zirconium powder=30 / 70, that is, 30g of tungsten powder and 70g of zirconium powder are weighed. Put it in a full-range planetary ball mill and mix for 1h, and mix well;

[0029] Molding: Put the uniformly mixed tungsten powder / zirconium powder in a hollow cylindrical mold for compression, the pressure is 30MPa, the pressurization rate is 30N / s, the pressure holding time is 4min, the pressure release rate is 30N / s, and the mold is released after the pressure release. obtain molded parts;

[0030] Sintering: Put the above-mentioned molded parts after demoulding in a sintering furnace for sintering, use an argon atmosphere during the sintering process, the sintering te...

Embodiment 2

[0037] A method for preparing a composite energetic fragment of an outer metal base and an inner polymer base, the specific steps are as follows:

[0038] (1) First prepare the outer metal-based hollow cylindrical specimen;

[0039] Weighing and powder mixing: the mass ratio of each component is: tungsten powder / zirconium powder=50 / 50, that is, 50g of tungsten powder and 50g of zirconium powder are weighed. Put it in a full-range planetary ball mill and mix for 1h, and mix well;

[0040] Molding: Put the uniformly mixed tungsten powder / zirconium powder in a hollow cylindrical mold for compression, the pressure is 30MPa, the pressurization rate is 30N / s, the pressure holding time is 4min, the pressure release rate is 30N / s, and the mold is released after the pressure release. obtain molded parts;

[0041] Sintering: Put the above-mentioned molded parts after demoulding in a sintering furnace for sintering, use an argon atmosphere during the sintering process, the sintering te...

Embodiment 3

[0048] A method for preparing a composite energetic fragment of an outer metal base and an inner polymer base, the specific steps are as follows:

[0049](1) First prepare the outer metal-based hollow cylindrical specimen;

[0050] Weighing and powder mixing: the mass ratio of each component is: tungsten powder / zirconium powder=70 / 30, that is, 70g of tungsten powder and 30g of zirconium powder are weighed. Put it in a full-range planetary ball mill and mix for 1h, and mix well;

[0051] Molding: Put the uniformly mixed tungsten powder / zirconium powder in a hollow cylindrical mold for compression, the pressure is 30MPa, the pressurization rate is 30N / s, the pressure holding time is 4min, the pressure release rate is 30N / s, and the mold is released after the pressure release. obtain molded parts;

[0052] Sintering: Place the above-mentioned molded parts after demoulding in a sintering furnace for sintering. During the sintering process, an argon atmosphere is used. The sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com