Main structure of green prefabricated building

It is a technology with green environmental protection and main structure, which is applied in the direction of building components, building structure, construction, etc., and can solve the problems such as the influence of the main body of the house on the thermal insulation effect and the poor thermal insulation effect of the foundation base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

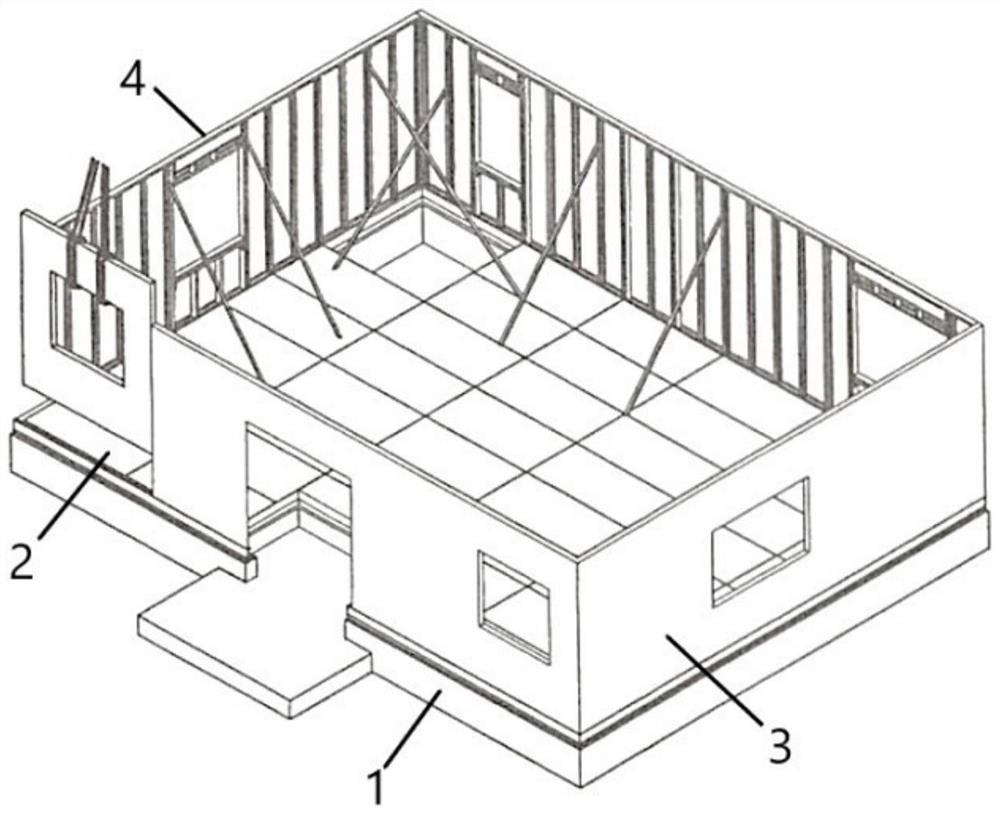

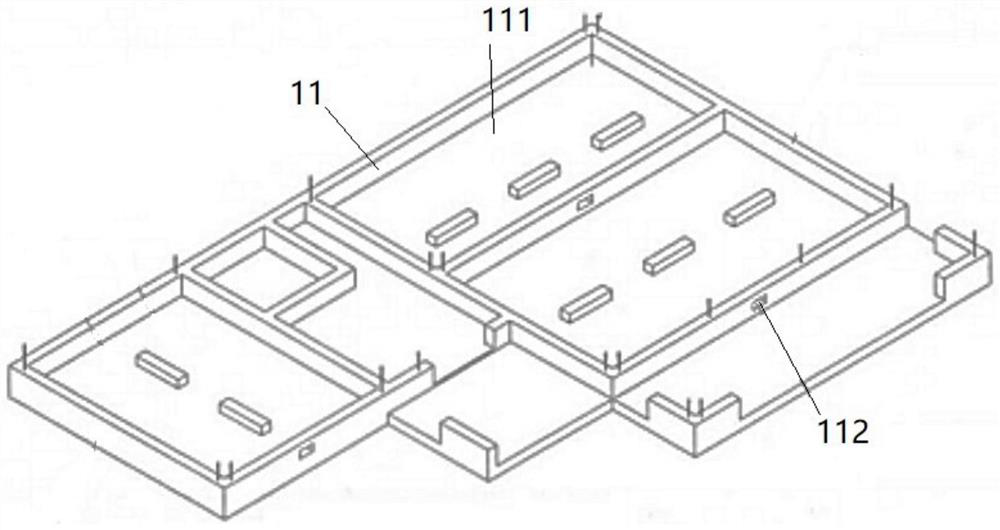

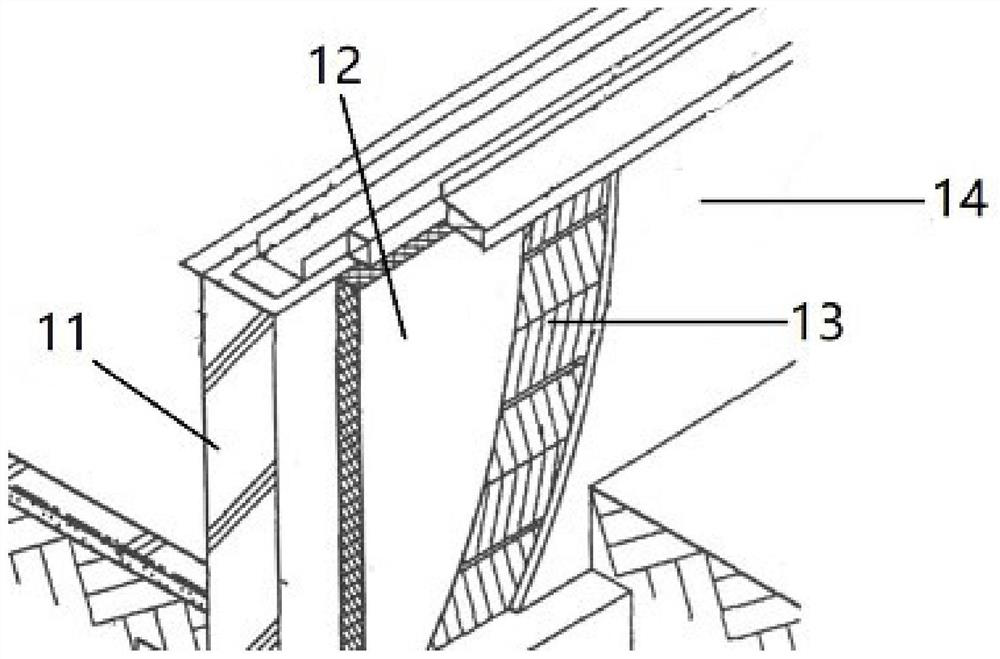

[0028] Embodiment 1: The main structure of a green environment-friendly prefabricated building, refer to the attached Figure 1-8 , including a base base 1, a floor 2 installed on the base base 1 and a wall 3 installed on the floor 2, the base base 1 includes a base wall 11 and several cavities 111 surrounded by the base wall 11 , there is at least one ventilation opening 112 on the foundation wall 11 surrounding each cavity 111, and the cavity 111 communicates with the outside through the ventilation opening 112, and a first heat preservation board is installed on the peripheral wall of the foundation wall 11 12. A reinforced mesh 13 is fixed on the outside of the first insulation board 12, and a cement mortar layer 14 is laid on the outside of the reinforcement mesh 13. The first insulation board 12 and the cement mortar layer 14 are provided with openings corresponding to the ventilation openings 112. Bit vias;

[0029] The floor 2 includes side beams 21 and floor beams 22...

Embodiment 2

[0032] Embodiment 2: The main structure of a green environment-friendly prefabricated building, refer to the attached Figure 1-8 , including a base base 1, a floor 2 installed on the base base 1 and a wall 3 installed on the floor 2, the base base 1 includes a base wall 11 and several cavities 111 surrounded by the base wall 11 , there is at least one ventilation opening 112 on the foundation wall 11 surrounding each cavity 111, and the cavity 111 communicates with the outside through the ventilation opening 112, and a first heat preservation board is installed on the peripheral wall of the foundation wall 11 12. A reinforced mesh 13 is fixed on the outside of the first insulation board 12, and a cement mortar layer 14 is laid on the outside of the reinforcement mesh 13. The first insulation board 12 and the cement mortar layer 14 are provided with openings corresponding to the ventilation openings 112. Bit vias;

[0033]The floor 2 includes side beams 21 and floor beams 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com