Underwater production system and underwater production method of fluidized mining based natural gas hydrate

A production system and natural gas technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of gasification and unobvious advantages in lifting efficiency, so as to avoid potential risks and reduce high-drop lifting Energy consumption and the effect of improving lifting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

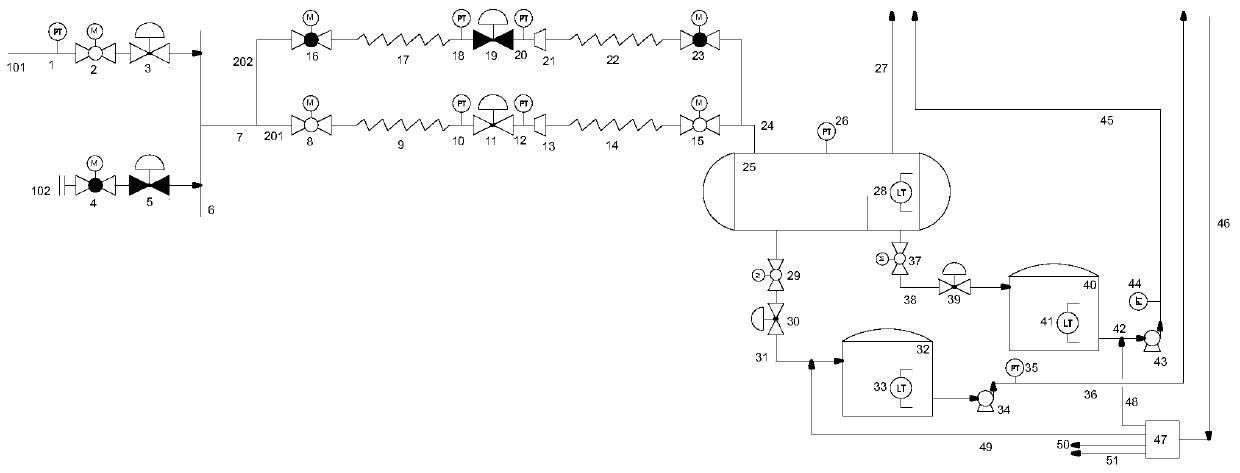

[0033] An underwater production system of natural gas hydrate based on fluidized mining, which mainly includes: collection pipeline 101, reserved collection pipeline 102, pressure transmitter 1, ball valve 2, regulating valve 3, reserved ball valve 4, reserved regulating valve 5. Underwater manifold 6, merged pipeline 7, normally open pipeline 201, standby pipeline 202, ball valve 8, primary crushing system 9, pressure transmitter 10, pressure reducing valve 11, pressure transmitter 12, expansion Diameter size head 13, secondary crushing system 14, ball valve 15, ball valve 16, primary crushing system 17, pressure transmitter 18, pressure reducing valve 19, pressure transmitter 20, expanding size head 21, secondary crushing system 22. Ball valve 23, separator inlet pipeline 24, horizontal weir plate separator 25, pressure transmitter 26, gas phase export pipeline 27, liquid level transmitter 28, ball valve 29, regulating valve 30, cement sand pipeline 31, Mud mortar storage tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com